Hydrothermal kiln for oats and sorghum

Optimize your grain production with advanced enzyme inactivation and hydrothermal treatment, ensuring uniform, premium quality in every batch while maintaining energy efficiency and meeting stringent food safety standards.

Hydrothermally Treats and Conditions Grains

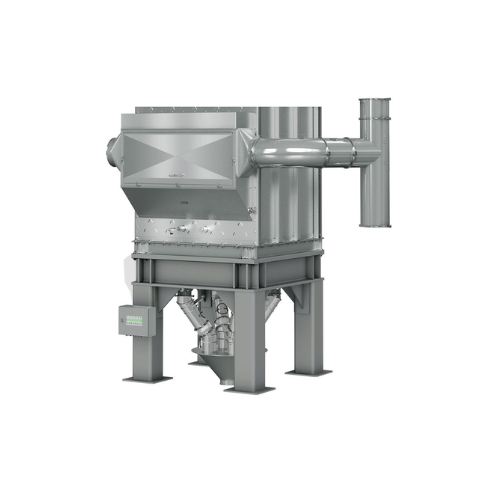

The Granotherm Kiln DNCB from Bühler Group is a modular hydrothermal treatment system designed for precise grain processing. It features a multi-section design with 2 to 8 heating sections and 1 to 3 cooling sections, adaptable to your desired throughput. The kiln’s stainless steel construction ensures durability and compliance with strict food safety standards, preventing residues and ensuring product purity. It processes grains such as oats and sorghum into end-products like oat flakes and sorghum flour while efficiently inactivating enzymes to prevent rancidity. The Granotherm Kiln is engineered for continuous operation with electronic cycle control for precise processing. Energy efficiency is enhanced through optimal insulation, reducing consumption. Cleaning is streamlined with easy-to-remove components and quick-access flaps, reducing downtime. Configurable to meet specific needs, it provides a reliable solution for food and feed industries committed to high-performance grain processing.

Benefits

- Configurable modular design maximizes production flexibility and efficiency.

- Minimizes energy usage through advanced insulation, reducing operational costs.

- Stainless steel construction ensures compliance with strict food safety standards.

- Enhances product stability by effectively inactivating spoilage-causing enzymes.

- Facilitates easy maintenance, decreasing downtime and maintenance-related expenses.

- Applications

- Snacks, Groats, Grain, Dairy, Grains, Oats, Sorghum, Pulses, Paddy, Spices, Aqua feed, Breakfast cereals, Animal feed, Pasta, Pet food, Nuts, Rice, Dried fruits, Baked goods, Oilseeds, Wheat, Confectionery, Vegetables

- End products

- Spaghetti, Livestock feed pellets, Dog kibble, Bread, Wheat flour, Sorghum flour, Cereal bars, Sun-dried tomatoes, Basmati rice, Parboiled rice, Muesli base, Canola oil, Jasmine rice, Cookies, Spice blends, Granola bars, Barley malt, Grain bars, Lentil flour, Macaroni, Milk powder, Cat food, Granola, Yogurt powder, Dried apricots, Groat granules, Oat flakes, Sorghum syrup, Cashews, Almonds, Sunflower oil, Rice cereal, Rolled oats, Crackers, Fish feed pellets, Raisins

- Steps before

- Drying, Dehulling, Sifting, Grain handling

- Steps after

- Cooling, Sorting, Weighing, Packing

- Input ingredients

- oats, sorghum, grains, groats

- Output ingredients

- uniform products, premium products, nutty taste

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Capacity

- Variable, configured per module

- Heating Sections

- 2 to 8

- Cooling Sections

- 1 to 3

- Material

- Stainless steel

- Energy Efficiency

- Low energy consumption

- Operation Time

- 24/7 operation

- Temperature Control

- Finely regulated

- Retention Time

- Adjustable

- Dosing

- Moisture and heat

- Modular design

- 2 to 8 heating sections, 1 to 3 cooling sections

- Temperature control

- Adjustable heating compartments

- Energy efficiency

- Low energy consumption

- Continuous operation capability

- Designed for 24/7 operation

- Cleaning method

- Easy maintenance and cleaning access

- Automation level

- Electronic cycle control

- Cleanability

- Stainless steel construction

- Corrosive resistance (e.g. acids)

- High, due to stainless steel

- Biological compatibility

- Food-grade stainless steel

- Modular Design

- 2 to 8 heating sections, 1 to 3 cooling sections

- Material

- Stainless Steel

- Configuration Options

- Customizable to throughput needs

- Modular design

- 2 to 8 heating sections, 1 to 3 cooling sections

- Stainless steel construction

- All parts in contact with the product

- Retention time control

- Adjustable

- Moisture and heat dosing

- Precise regulation

- Electronic cycle control

- Finely regulated process