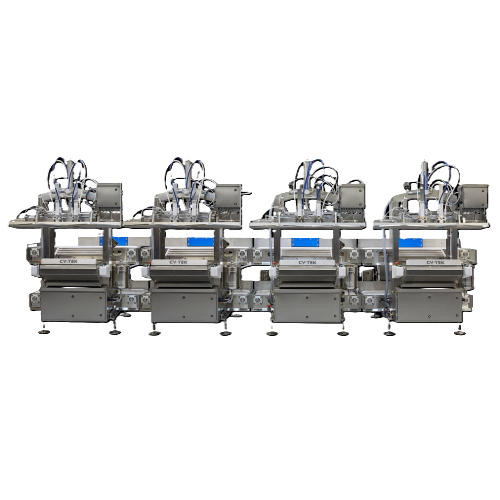

Multi-station modified atmosphere packaging system for bulk products

Optimize your packaging efficiency with a system designed for high-speed, multi-station operations, perfect for maintaining product freshness and extending shelf life through precise modified atmosphere techniques.

Packages and Seals with Modified Atmosphere

The MARK III mHSP from CV-TEK is a versatile multi-station modified atmosphere packaging machine designed for the food processing industry. This machine integrates seamlessly into packaging lines, utilizing a combination of vacuuming, sealing, and gas flushing to maintain product integrity and extend shelf life. Available in configurations of 2, 3, or 4 modules, it offers unmatched flexibility and scalability, allowing you to adapt to changing production needs with ease.

Each module features independent infeed and outfeed belts, supported by Smart-Belt technology for precise material handling, ensuring high throughput with minimal product loss. The stainless steel construction meets USDA standards, offering resistance to harsh washdown environments and ensuring sanitary conditions. Incorporating safety features such as self-locking ratcheted seal bars and TÜV-certified control systems, the MARK III mHSP maintains a focus on operator safety.

Common applications include the packaging of snacks, sweets, sauces, and more, with end products like potato chips and ready-to-eat meals. Designed for high-speed operations, this machine accommodates vacuum pumps and gas probes suitable for CO2 and N2, with energy-efficient options minimizing operational costs. Whether you’re handling bulk goods or dairy products, the MARK III mHSP delivers robust performance tailored to your specific needs.

Benefits

- Increases shelf life and product freshness through efficient modified atmosphere packaging.

- Customizable modular design provides flexibility to scale operations as needed.

- Ensures operator safety with self-locking seal bars and safety features.

- Lowers operational costs due to energy-efficient vacuum and gas flushing systems.

- Facilitates quick maintenance with tool-free access for cleaning and inspection.

- Applications

- Sauces, Snacks, Pet food, Processed foods, Bulk food products, Nuts, Sweets, Cereals, Spices, Packaged foods

- End products

- Canned beans, Cornflakes, Dry dog food, Potato chips, Chocolate bars, Ground cinnamon, Rice, Ready-to-eat meals, Tomato sauce, Almonds

- Steps before

- Product Preparation, Material Loading

- Steps after

- Final Packaging, Distribution

- Input ingredients

- vacuum-gas probes, C02, N2

- Output ingredients

- packaged products, sealed packages

- Market info

- CV-TEK (Middleby) is known for its expertise in designing and manufacturing modified atmosphere packaging (MAP) systems, offering innovative packaging solutions that enhance product shelf life and quality in the food processing industry.

- Seal Bar Length

- 54 inches (1370mm)

- Gas Accumulator Tank

- SS for higher speeds

- Infeed/Outfeed Belt Width

- 18 inches, optional 22 inches

- Vacuum/Gas Probes Material

- 100% Teflon, 100% sanitize-able

- Air Line Requirement

- 5 cfm @ 100 psi – 1-inch line

- Gas Line Requirement

- 3/4-inch line at 100psi

- Voltage Requirement

- 3 ph / 60 hz / 440/480 V – 10 amps per station

- Vacuum Pump Type

- Dry-vane or water-ring (additional charge)

- Vacuum Pump Capacity

- 38 CFM

- Frame Material

- 7-gauge polished stainless steel

- Control System

- Wired to UL specifications, CE self-certifying

- Automation Level

- Semi-auto multi-function

- Temperature and Pressure Resistance

- High-pressure, high-temperature caustic wash

- Modular Configuration

- 2, 3, 4+ stations, expandable

- Smart-Belt Technology

- Detects and stops/starts infeed belt

- Safety Features

- Self-locking safety ratcheted seal bar lock

- Hose Types

- White hose (vacuum), Blue hose (gas)

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- PLC / Manual

- Changeover time

- Minimal with modular addition

- Cleaning method

- Manual / Easy to sanitize components

- CIP/SIP

- Not mentioned

- Energy efficiency

- Not explicitly mentioned

- Integration flexibility

- Modular with customized station additions

- Adaptation capability

- Module addition in minutes

- Cleanability

- 100% sanitize-able

- Open,easy to inspect

- Corrosive resistance (e.g. acids)

- Stainless steel components

- Shape and size of seal bars

- 54-inch (1370mm) lector-polished

- Tank material

- Stainless steel

- Feed method

- Infeed belt

- Discharge method

- Outfeed belt

- Frame material

- 7-gauge polished stainless steel

- Control panel type

- Smart-Belt technology

- Vacuum and gas probes material

- 100% Teflon

- Control panel type

- Two-hand controls, Semi-auto multi-function

- Integration possibilities

- Modular infeed/outfeed belts, Easy module addition with water-tight cable

- Seal bar size

- 54-inch (1370mm) lector-polished

- Material

- Solid 7-gauge polished stainless steel

- Gas accumulator tank

- SS gas accumulator tank for higher speeds

- Hose type

- White vacuum, Blue gas (C02 or N2)

- Vacuum/gas probes material

- 100% Teflon

- Frame construction

- Solid frame, high-pressure wash

- Seal bar safety feature

- Self-locking safety ratcheted seal bar lock