Making Flour

Find innovative production technology for making flour and connect directly with world-leading specialists

Flour processing technology has changed drastically since the days of the millstone pulled by a mule. But demand for more refined flour means that the production process is now slower than with more rudimentary techniques. When mixed with water, protein in wheat flour form an elastic gluten structure, giving bakery products their irresistible fluffiness.

Select your flour process

Tell us about your production challenge

Refine the sifted grain with a secondary sieving

The wheat grain is composed of bran, endosperm, and germ. The bran and germ are sifted out, leaving behind the carbohydrate-rich endosperm. Before modern flour processing technology, the traditional way to sift was throwing the grains up in the air and letting the lighter chaff be blown away by the wind.

After sifting, the endosperm is ready to undergo a second sieving process to refine the material in preparation for further milling.

Water conditioning peels off the outer layer more easily

Before going for grinding, grains are treated with water to facilitate the removal of the outer skin. Cold conditioning involves soaking the wheat in cold water for up to three days. Warm conditioning, by contrast, immerses the material in water at temperatures around 46°C for 60-90 minutes and lets it rest for one day.

Water temperatures are sometimes ramped up to 60°C in a technique known as hot conditioning. In this method, grains are soaked for a shorter time. An alternative approach applies steam to the material instead of water immersion.

Apply semi-wet grinding to produce gluten-free flour from rice

Rice flour is a good substitute for rye, oat, or wheat flour. Its protein content is about 6.5-7%, but it does not contain gluten, making it an ideal candidate for gluten-free products.

The grinding process typically adopts a semi-wet method. Rice is fermented in water at a 1:2 ratio for 16 hours and then crushed. The material is partially dried in oven dryers operating at 60°C until the moisture content is reduced to around 24%. It is then ready to be milled again into finer particles and dried thoroughly.

Convert chaff from flour processing technology into wheatfeed

The bran discarded at the sifting stage is a rich component for feeds. Although frequently used in pig and poultry products, wheatfeed offers a good source of fiber and phosphorous in all types of livestock feeds.

The by-product is naturally low in calcium and vitamins, but it can be blended with other ingredients to produce a balanced feed premix. Wheatfeed is usually processed into pellet feed.

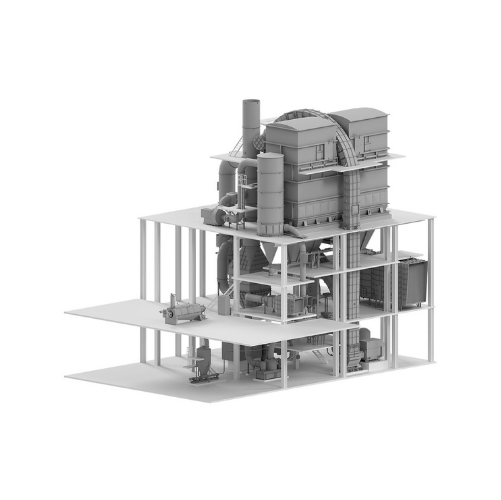

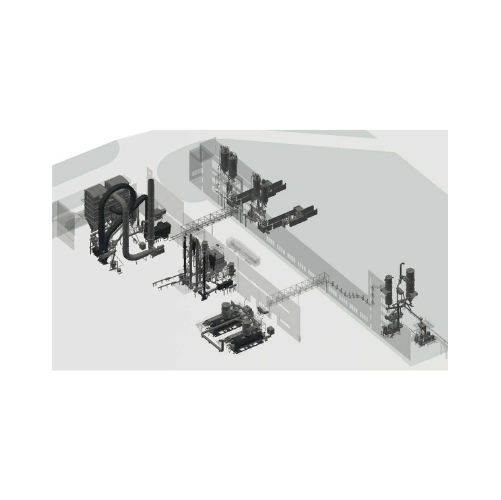

Processing steps involved in flour making

Which flour technology do you need?

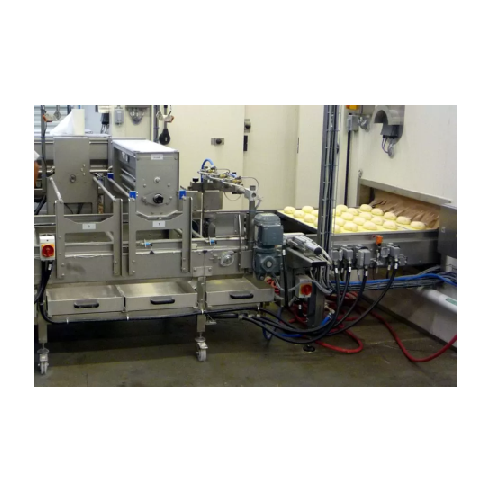

Cake and pastry depanner

Optimize your bakery’s output with this solution that seamlessly integrates into your production lin...

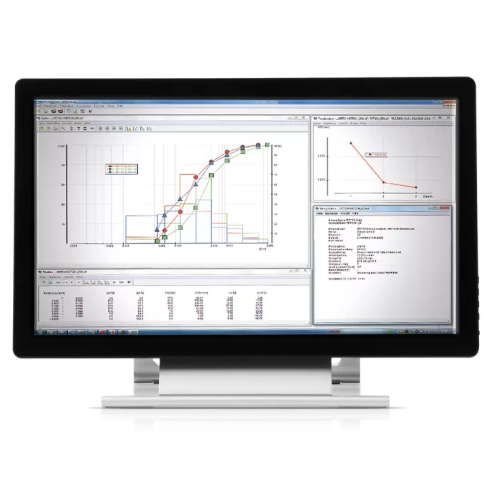

Sieve analysis software for automated evaluation

Streamline your sieving processes with automated data evaluation and prec...

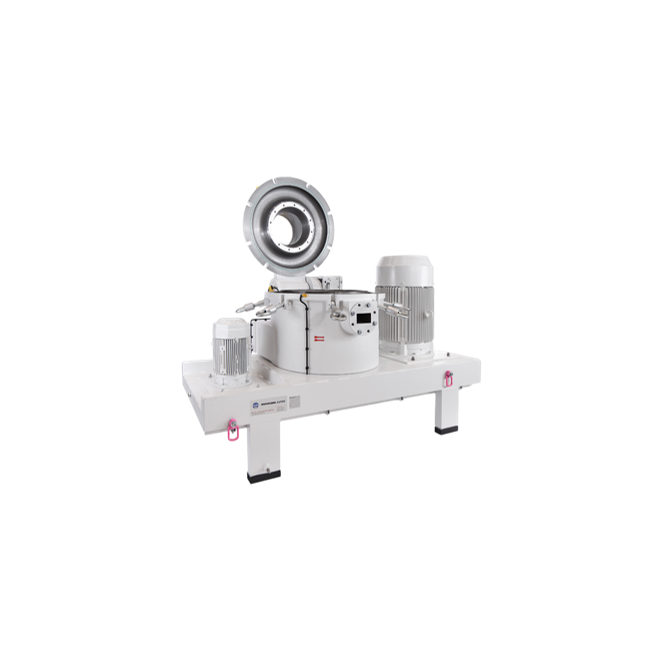

Electromagnetic sieve shaker for quality control

Achieve precise particle size distribution with this advanced electromagn...

Mesh sieves for laboratory particle size analysis

Ensure precise particle size control for a wide range of materials with...

Perforated plate sieves for particle size determination

Optimize your particle size separation with high-stability stainl...

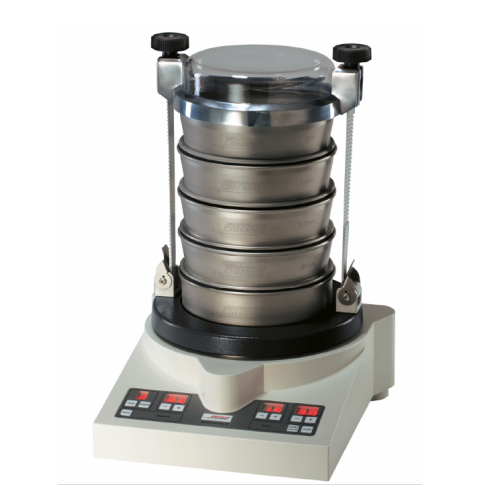

Vibratory sieve shaker

Enhance your quality control processes with this versatile sieve shaker, designed to efficiently separ...

Vibratory sieve shaker for particle size determination

Achieve precise particle size analysis with rapid, reproducible re...

Vibratory feeder for bulk materials and fine powders

Ensure consistent material flow and precise feeding for optimized pr...

Sample divider for on-site reduction of bulk materials

Ensure consistent sample analysis with precise on-site material di...

Sample dividing solutions for laboratory applications

Streamline your lab’s precision in sample preparation with so...

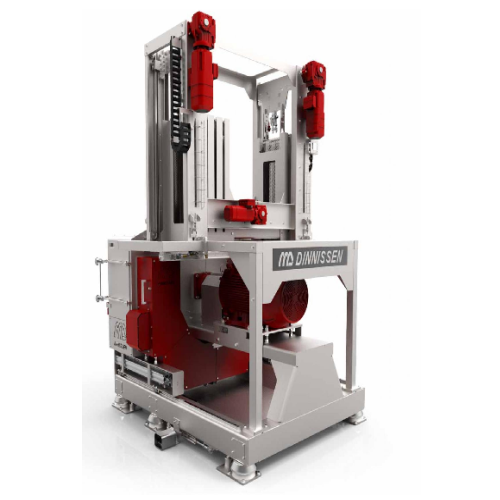

Powder sifters for industrial applications

Optimize powder consistency and enhance production flow with advanced sifting t...

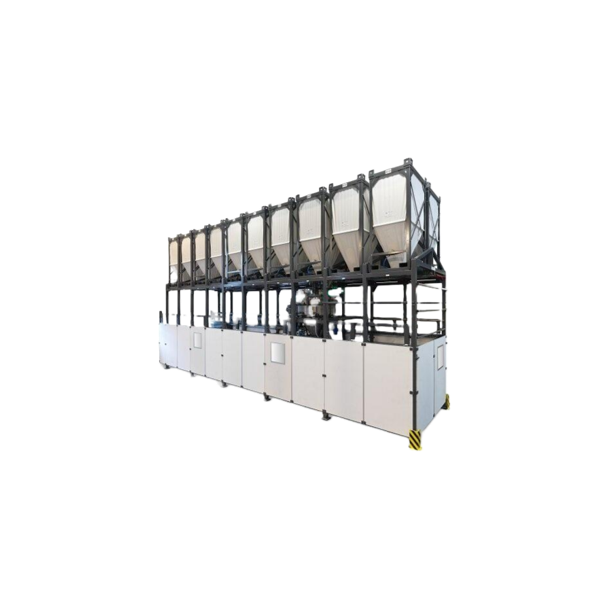

Powder unloading systems for food and dairy applications

Streamline your powder handling with customizable unloading syst...

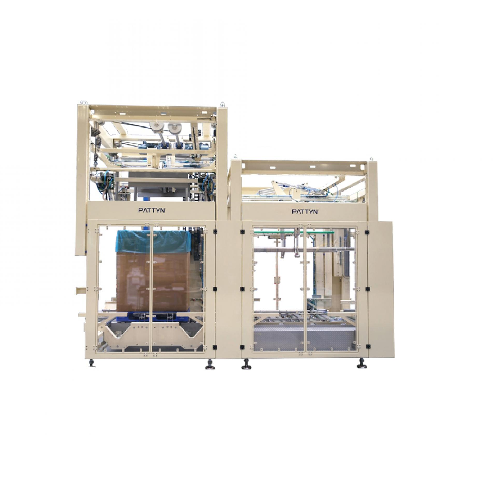

Industrial Xl bag sealer for large pallet containers

Eliminate manual handling and ensure perfect seals for bulk packagin...

Cryloc rotary screens for grain processing

Efficiently sort and separate fine particles with high precision to enhance pro...

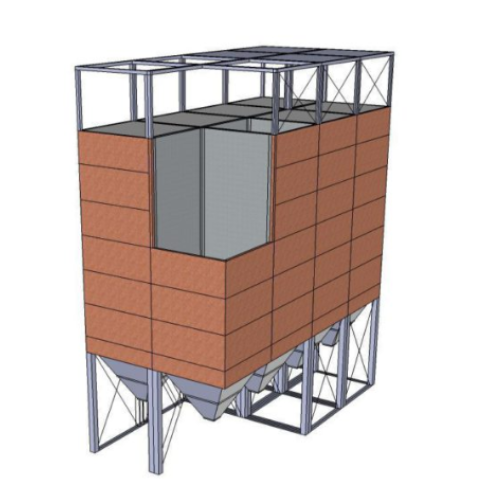

Square silo for bulk goods storage

Maximize your storage efficiency by 25% with square silos, uniquely designed for effecti...

Bucket elevators for bulk material handling

Efficiently transport and discharge granular and powdered materials with preci...

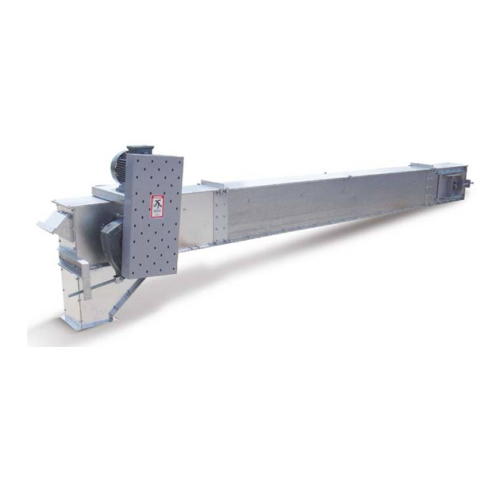

Efficient powder and granulate flight conveyors

Elevate your production efficiency with our cutting-edge flight conveyors,...

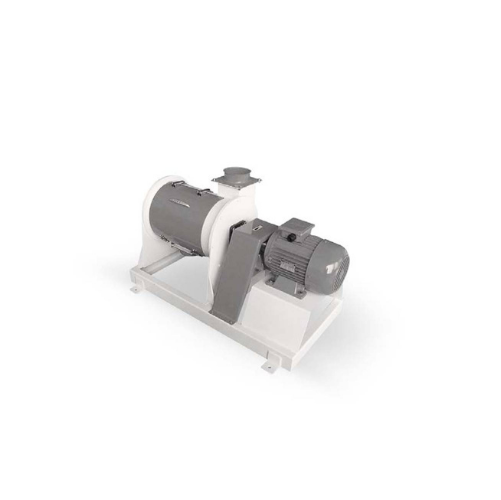

Rotary dischargers for powders and granules

Prevent production halts with this solution designed for efficient discharge o...

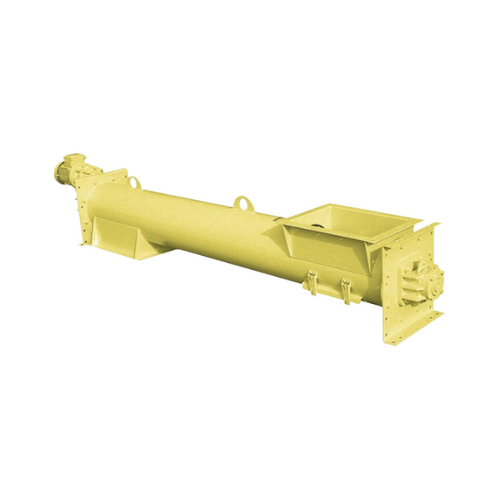

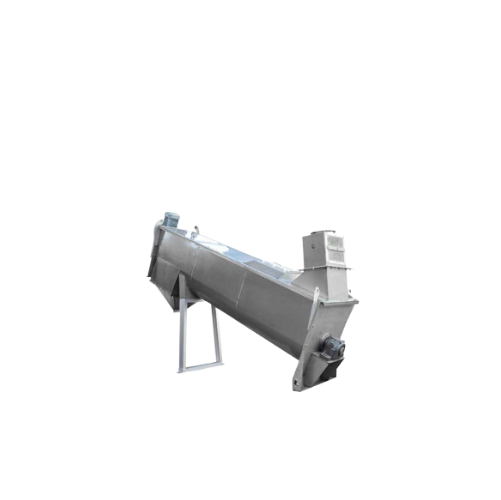

Screw conveyors for grain processing and feed mills

Optimize your production line with versatile screw conveyors, designe...

Self-driving transport system for industrial packaging

Streamline internal logistics with a self-navigating vehicle desig...

Compact sealing system for bags and boxes

Achieve seamless, high-speed packaging with a compact solution designed to handl...

Silo unloader for difficult products

Tackle challenging silo extractions with a robust unloading system designed for high-s...

Sweep auger for flat bottom silos

Optimize your grain storage operations with a fully automatic sweep auger designed to eff...

Unloader for conical bottom silos

Eliminate product flow challenges effortlessly with this hydraulic-driven unloader, ensur...

Dough proofing solution for stress-free fermented dough

Ensure stress-free dough handling and optimal fermentation before...

Circular sifter for fatty products and flours

Achieve precise separation and grading of nuts and flours, optimizing your p...

Versatile bread slicer for bakeries and supermarkets

Effortlessly slice various bread types with precision and speed, ens...

Flake ice weighing and batching system for dough processing

Optimize your dough’s freshness and consistency with p...

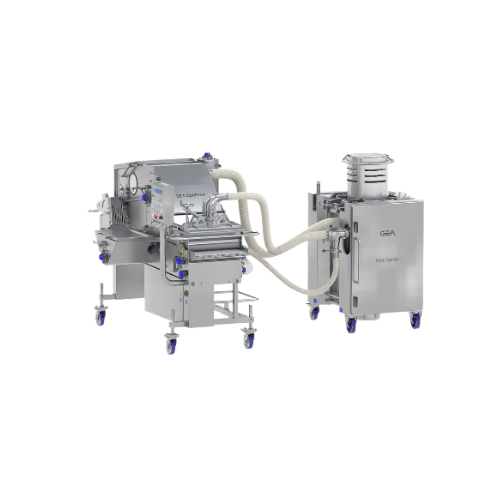

Flour applicator for convenience foods and snacks

Achieve uniformly coated products, such as chicken nuggets and fish fil...

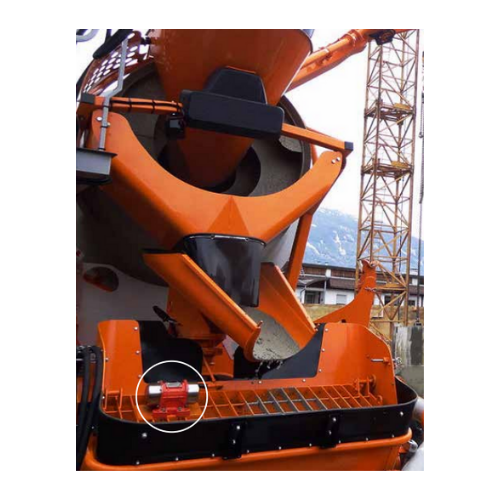

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

Cryogenic chilling systems for food processing

Efficiently maintain precise temperatures to enhance product quality and sa...

Cryogenic chilling for food processing

Optimize your food production line with cutting-edge cryogenic chilling solutions, d...

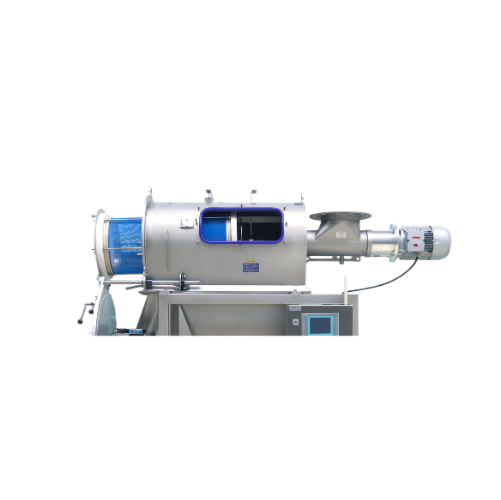

Industrial mixer for vegetable, powder, rice, noodle blending

Effortlessly achieve consistent blends with this 100-liter...

Commercial food drum mixer for sauerkraut and salads

Streamline your batch production with this versatile commercial food...

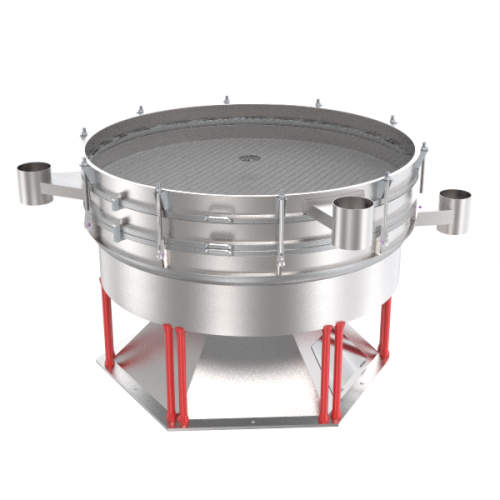

Vibrating tumbler screener for dry and wet screening

Achieve efficient dry and wet material separation with a high-capaci...

Universal mill for fine grinding in food and pharma industries

Achieve unparalleled particle size reduction with high-pe...

High-speed centrifugal sifter for food and pharma applications

Optimize your powder processing with a high-speed centrif...

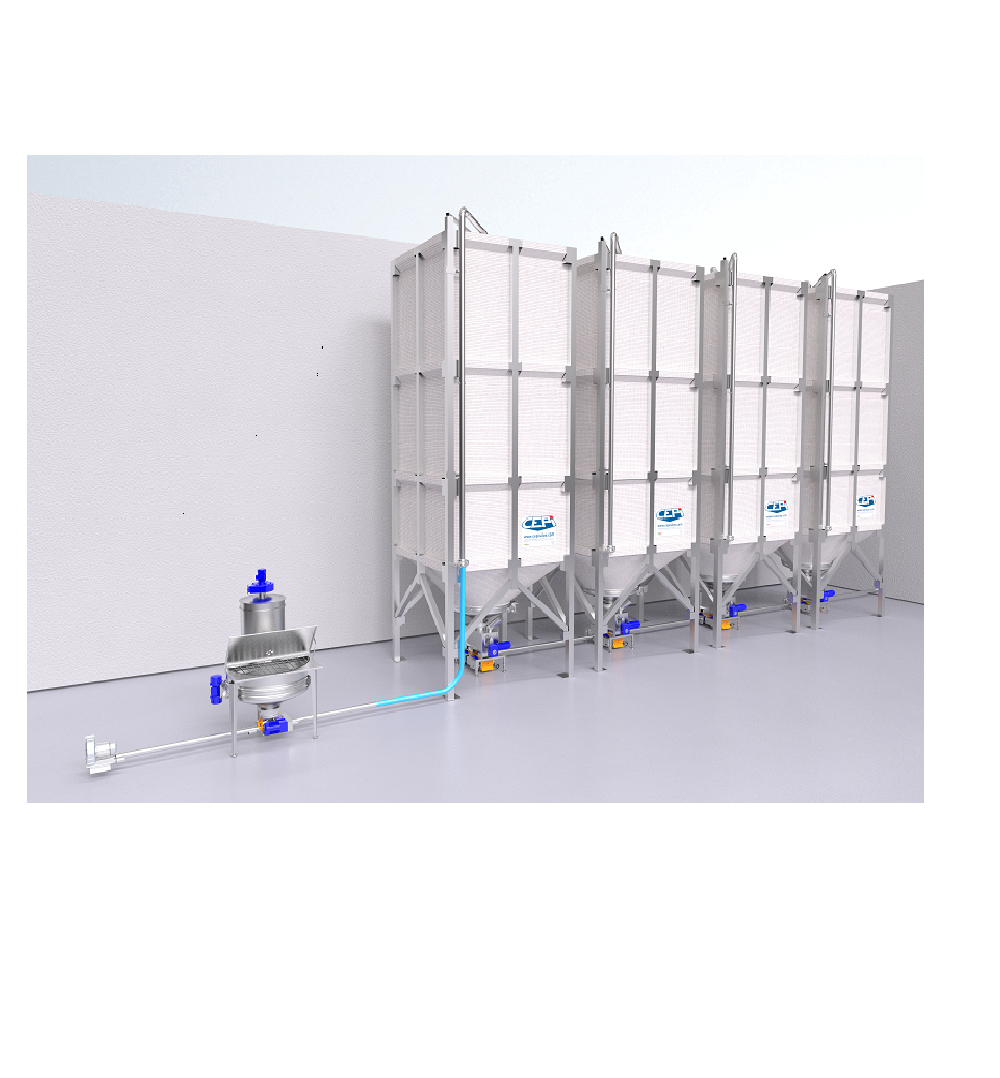

Industrial silos for powdered and granulated products

Optimize your storage and material flow for powdered and granulated...

Bag dump station for handling solid foodstuffs

Efficiently manage manual dosing of solid foodstuffs and powders with this ...

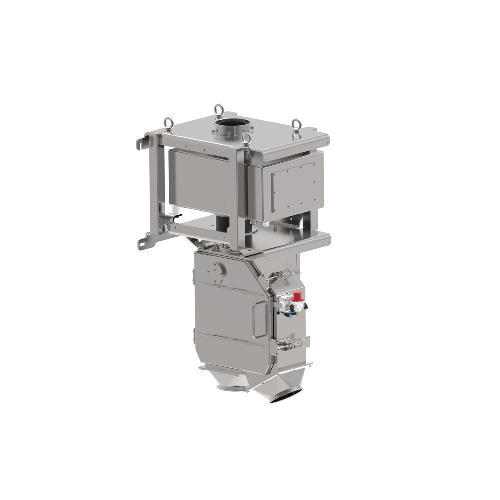

Big bag unloading station for solid materials

Streamline your production line by efficiently handling and dosing bulk soli...

Micro ingredients loading station for solid additives

Optimize precision dosing and ensure smooth transfer of powdered in...

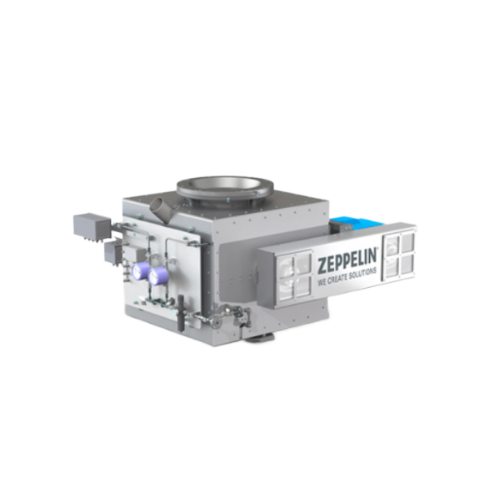

Industrial sieving solution for solid materials

Effortlessly separate impurities and adjust particle size for optimal prod...

Industrial v-type solids blender for homogeneous mixture

Achieve precise blending of diverse powders and solids using the...

Buffer tanks for powdered or granulated solids storage

Enhance your production line with buffer tanks designed for precis...

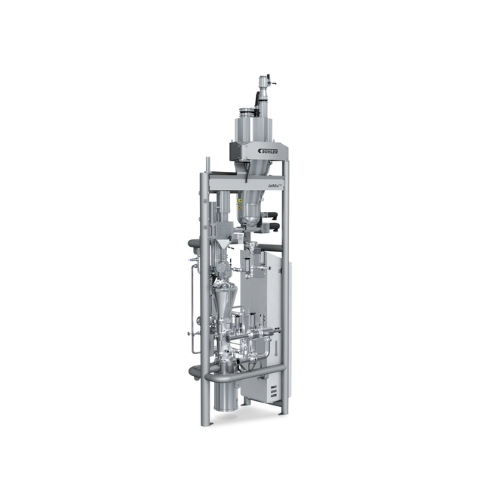

Continuous vertical form fill seal packaging solution

Experience unrivaled accessibility and efficiency in packaging fres...

Rotary doypack packaging system for various materials

Enhance your packaging line with versatile doypack machines designe...

Rotary doypack for granules, liquids, and powders

Enhance your packaging line with a rotary doypack system designed to ef...

Tray sealing machine for buckets

Ensure efficient sealing and preservation with high-speed tray sealing for various food pro...

Vertical stick pack sachet packaging solution

Ideal for mid-scale operations, this vertical stick pack machine streamlines...

Automatic vertical casepacker for efficient packaging integration

Streamline your packaging process with a vertical cas...

Tray sealer for food packaging buckets

Enhance your packaging efficiency with a highly adaptable tray sealer, designed for ...

Tray sealer for packaged food products

Optimize your food packaging with precise sealing and advanced Modified Atmosphere P...

Traysealer for medium production

Streamline your packaging process with high-speed traysealing, ensuring freshness and exten...

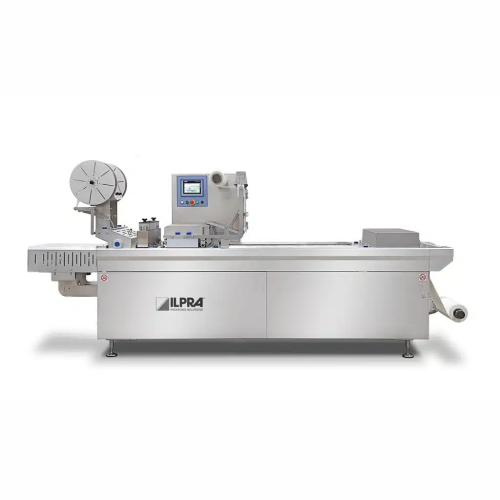

Thermoforming packaging solution for food and medical applications

Enhance your packaging line with a solution designed...

Compact thermoforming packaging system for food industry

Revolutionize your packaging line with a space-saving solution t...

Linear and auger weighing systems for non-free-flowing products

Optimize your production line with precise weighing and ...

Metal detector for small to medium-sized products

Ensure product integrity and compliance by seamlessly integrating metal...

Multi head weigher for precise portioning

Ensure consistent product portions with our multi head weigher, ideal for high-s...

Vertical form fill seal for small to medium production runs

Ideal for scaling production, this compact packaging solutio...

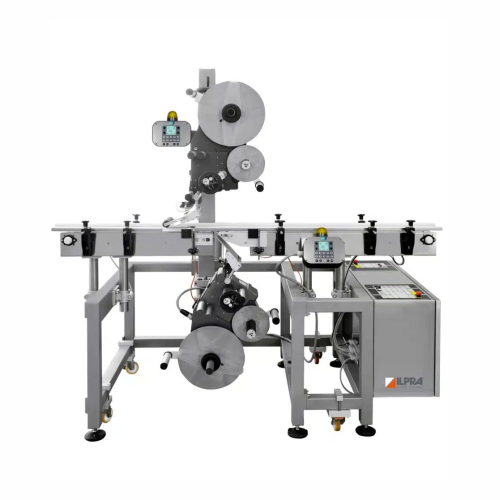

Automatic c-wrap labelling for packaged products

Enhance your production line with precise C-wrap labelling, seamlessly in...

Automatic top & bottom labelling system

Enhance your packaging line efficiency by applying precise top and bottom labels to...

Industrial check-weigher for accurate product weight verification

Ensure precise weight compliance and reduce waste wit...

Rotary filler and sealer for dairy products

Optimize your filling and sealing needs with a compact solution designed for c...

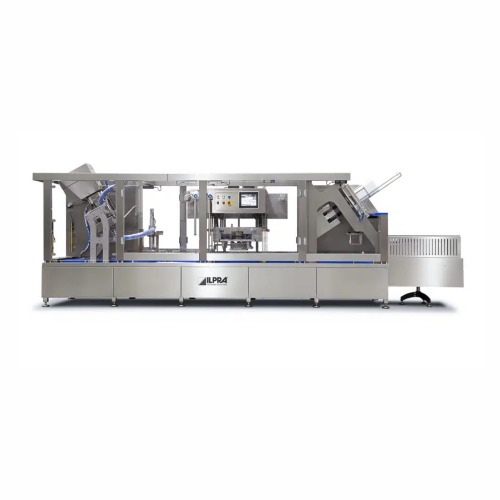

Automatic filling and sealing solution for medium to large production

Streamline your high-capacity filling and sealing...

Rotary filler for optimized production processes

Streamline your fill and seal process with precise timing control and enh...

Entry-level in-line traysealer for ready-to-eat meals

Streamline your ready meal packaging with a compact traysealer that...

Semi-automatic tray sealer for skin packaging

Optimize your small-scale food packaging with a compact tray sealer designed...

Pneumatic conveying systems for industrial applications

Efficiently transport bulk materials or liquids across your produ...

Industrial pick and place system for packaging

Streamline your packaging line with precise robotic pick and place operatio...

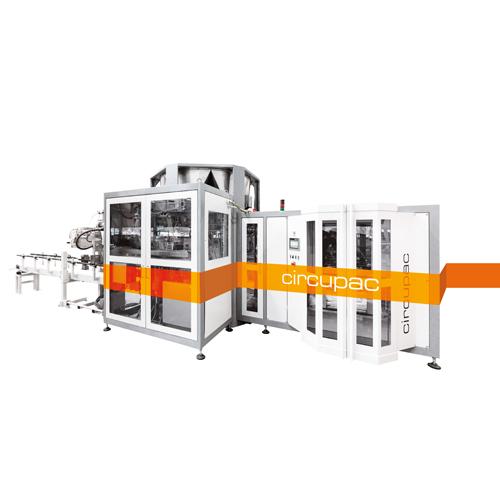

High-speed continuous rotating packaging solution

Transform your packaging efficiency with versatile operations, accommod...

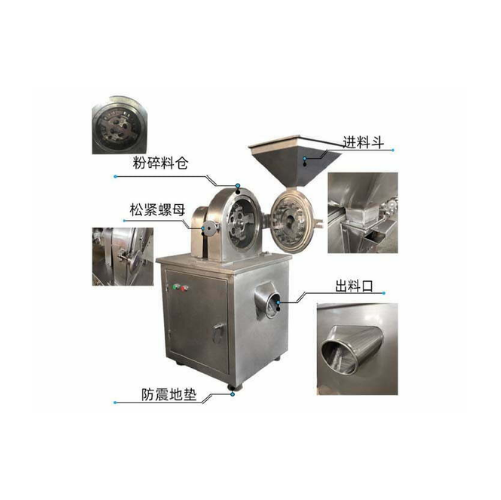

Industrial powder grinder

Achieve precise particle size reduction and classification with advanced equipment designed for co...

Vacuum dryers for powders and bulk solids

Achieve precise drying and mixing of sensitive materials with advanced vacuum te...

Pneumatic conveying system for bulk material handling

Efficiently transport bulk materials with precision through pneumat...

Industrial pre-crusher for coarse crushing

Optimize your production line by efficiently transforming clumped materials int...

Table roller mills for mineral raw material comminution

Achieve precise mineral raw material comminution and energy-effic...

Fluidised bed opposed jet mill for fine particle processing

Achieve precise and consistent particle sizes with high-spee...

Jet mill for toner and pigment industries

Optimize particle size and distribution for high-demand applications with this h...

Roller press for fine-grained material compaction

Achieve optimal density and stability in your solid press agglomerates ...

High-pressure roller compactors for chemical, food, and minerals industries

Achieve precise particle compaction and br...

Multiprocessing system for flexible research and production

Optimize your process development with a versatile system th...

Pelleting and spheronizing equipment for chemical granulates

Optimize your production line with versatile pelleting and ...

Low-dust granulator for plastic parts recycling

Achieve efficient comminution with minimized dust generation, ideal for pr...

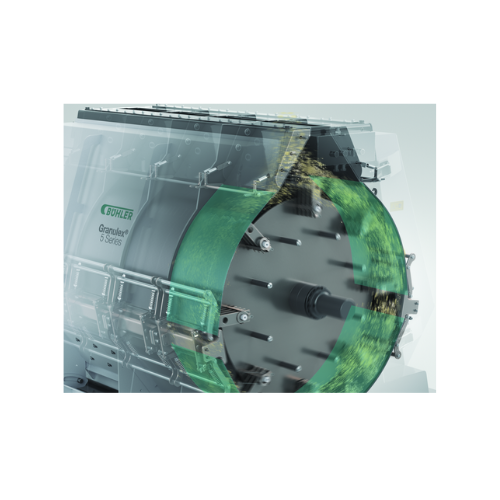

Industrial granulator for high-throughput plastic recycling

Facing challenges in efficiently recycling high-volume plast...

High pressure roller mill for medium-fine crushing

Achieve precision in particle size with high-pressure roller mills, id...

High-pressure roller mill for medium-fine crushing

Achieve precise granule distribution in medium-fine crushing applicati...

Spiral jet mill for superfine powder production

Achieve consistent ultra-fine powder with precise particle size control, c...

Fluidised bed opposed jet mill for ultrafine powder production

Achieve contamination-free ultrafine powder milling with ...

Sugar grinding and recrystallization system

Optimize your sugar production with a system that integrates grinding and recr...

Versatile fine impact mill for soft materials

Achieve precision grinding with flexibility for a wide range of materials, e...

Flake crushers for gentle crushing of brittle materials

For processes needing precise granule control, our equipment ensu...

Industrial granulators for plastic recycling

Streamline your recycling operations with a solution that not only reduces en...

Fine cutting mill for soft to medium-hard plastics

Achieve precise size reduction and smooth particle shapes in plastic p...

Compact granulator for plastic comminution

Optimize your plastic recycling operations with a compact granulator designed t...

Heavy-duty shredder for difficult materials

Struggling with stubborn materials that resist conventional shredding? This ro...

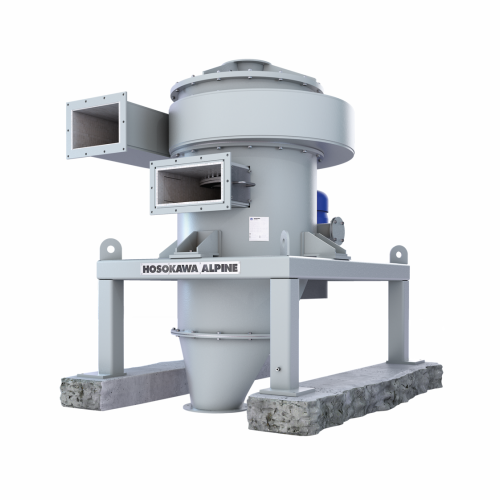

Air classifier for fine powder processing

Enhance your production line with precise particle size control and energy-effic...

Gravity classifier for precise particle separation

Achieve sharp separations in particle processing with minimal maintena...

Ultrafine classifier for toner and pigments

Achieve unparalleled precision in classifying fine powders essential for high-...

Ultrafine air classifier for powder separation

Achieve precise particle separation with technology designed to enhance you...

Ultrafine classifier for soft to medium-hard mineral processing

Achieve exceptional particle precision with an ultrafine...

Discharge systems for difficult bulk materials

Achieve seamless bulk material discharge with our advanced systems that eff...

Automatic bulk material filling system

Ensure precise, contamination-free filling of various bulk materials with an advance...

Powder flowability and compressibility analysis

Ensure accurate powder flowability and compressibility data with this adva...

Dry grinding mill for superfine products

Achieve high fineness in your comminution processes with this advanced dry grindin...

Ball mill for dry comminution of hard materials

Achieve ultrafine particle sizes and precise material breakdown with this ...

Air classifier for fine to medium-fine separation

Reduce energy consumption and wear while achieving high precision in th...

Laboratory system for powder and particle processing

When precision in powder processing is crucial, this versatile labor...

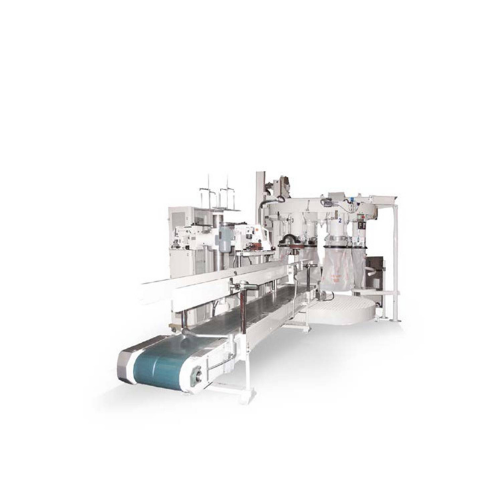

Stationary entry packaging system for valve bags

Optimize your packaging workflow with a high-speed, modular filling syste...

Integrated packaging system for valve and tubular film bags

Achieve precision and efficiency in your packaging line with...

Fully automatic bag applicator for valve bags

Maximize your packaging line efficiency with a high-speed system that seamle...

Stainless steel intermediate bulk containers for pharmaceutical use

Ensure safe, efficient transport and handling of po...

High capacity production milling for bulk materials

Optimize your production with our high-capacity milling solution, des...

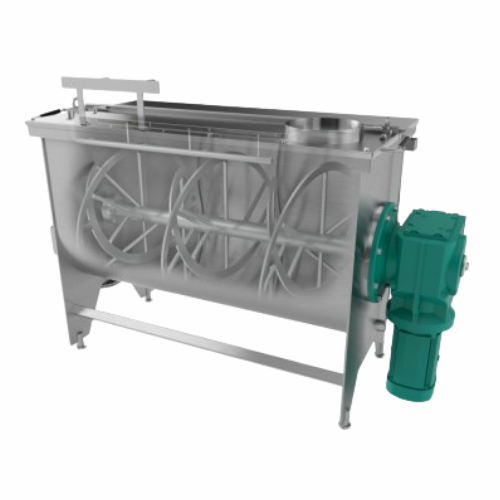

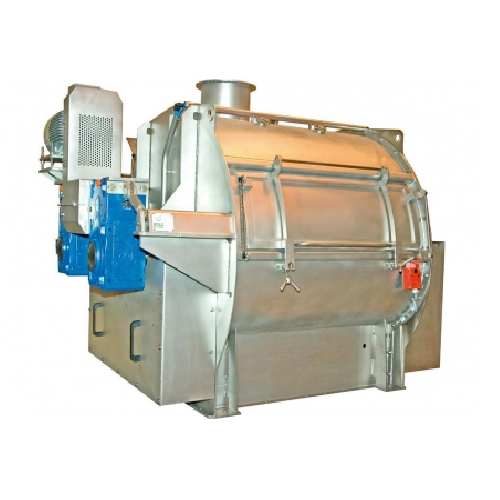

Ribbon blender for homogeneous blending of solids

Achieve perfectly consistent blends with a ribbon blender that ensures ...

Continuous mechanical clipband closing system for bags

Streamline your bakery packaging process with a high-speed clipban...

Vibratory sieve shaker for precise particle size distribution

Achieve precise particle size distribution with advanced v...

Variable speed rotor mill for sample preparation

Achieve rapid and precise grinding of various materials with a versatile ...

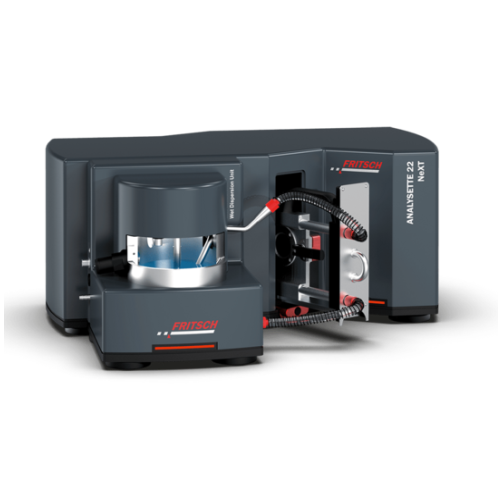

Laser particle sizer for accurate particle size distribution

Achieve precise control over particle size distribution wit...

Vibratory micro mill for fine comminution

Achieve precise particle size reduction and homogeneity for medium-hard to britt...

Advanced dough mixing solution with removable bowl

Efficiently blending and kneading diverse doughs, this mixer enhances ...

Premium stainless steel spiral mixer for doughs

Perfect for bakeries aiming to deliver consistent artisan breads, this spi...

Sourdough fermentation unit for rye pre-doughs

Optimize your sourdough production with this compact unit, enabling precise...

Hammer mill with automatic screen exchange

Optimize your milling operations with a high-speed solution that ensures seamle...

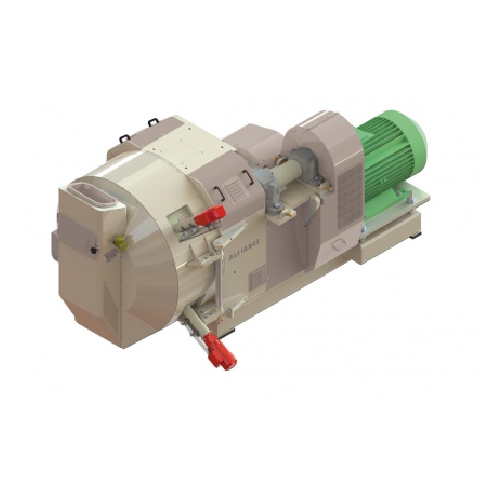

Industrial hammer mill for grinding and sifting

Ensure precise particle size reduction and consistent product quality with...

Industrial centrifugal sifter for solid particulate materials

Quickly and accurately sift a wide range of powders and gr...

Roller mills for high-demand crushing applications

Optimize your production line with versatile roller mills designed to ...

Heavy-duty roll crushers for crushing applications

Optimize your crushing and grinding processes with robust roll crusher...

Efficient barley malt crushing with roller mills

Achieve precise particle size control in your processing line with a robu...

Bulk bag weighing system for batching operations

Streamline your batching process by accurately weighing minor ingredients...

Industrial hammermill for size reduction

Optimize your production line with high-efficiency size reduction, designed to han...

Precision feeders and mixers for plastics processing

Achieve precise blending and feeding for plastics processing with mo...

Industrial smart flow meter

Ensure precise metering and smooth handling of bulk materials with a device that eliminates movi...

Food extruders for pet food production

Achieve precise control in food production with advanced twin screw extruders, desig...

Grain separator for impurity removal in milling

Optimize grain cleaning with a high-performance separator designed to effi...

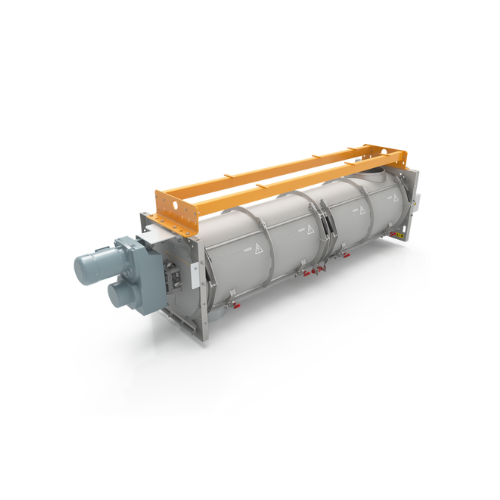

High-capacity tubular screw conveyor for grain transport

Optimize your production flow with a robust solution that ensure...

High-throughput grain cleaner

Maximize efficiency in grain processing with a high-throughput cleaner designed to handle dive...

Vertical hammer mill for feed and grain processing

Optimize your milling operations and improve energy efficiency with th...

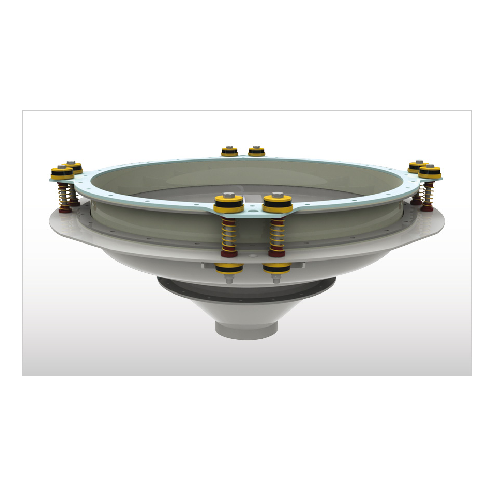

Vibro discharger for silo emptying

Achieve complete and even discharging of bulk materials from various silo types, ensurin...

Efficient grain destoning and concentrating system

Optimize your grain processing with a solution that ensures precise se...

Automatic rice whitening solution

Need consistent rice whiteness and bran removal without manual intervention? This high-sp...

Vertical rice whitener

Optimize rice and grain outputs with high-yield vertical whitening technology, designed to preserve pr...

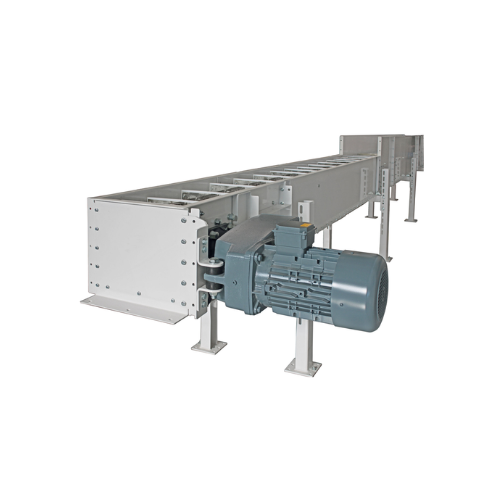

Chain conveyor for grain and floury products

Ensure seamless material handling with a versatile chain conveyor designed fo...

Trough screw conveyor for grain transport

Streamline your grain processing with a reliable conveyor system that ensures ef...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Optical sorter for coffee, grains, nuts, and plastic flakes

Ensure precise defect detection and foreign material removal...

Optical sorter for grains, coffee, nuts, and plastics

Ensure consistent product quality and minimize waste with advanced ...

Optical sorter for rice

Enhance your product quality by efficiently sorting and removing color defects and foreign materials ...

Batch mixer for animal feed

Streamline your mixing process with a high-speed batch mixer that delivers up to 20 mixing cycle...

Purifier for high-quality semolina production

Achieve consistent semolina purity with this high-capacity purifier, ensurin...

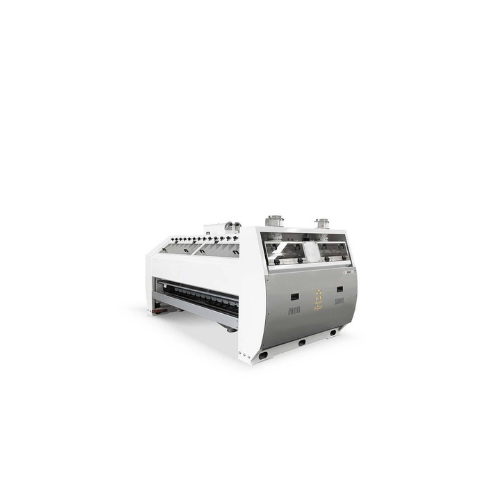

Four-roller and eight-roller mill for wheat and grain grinding

Optimize your grinding operations with this versatile rol...

Grain scourer for wheat, durum, and rye

Enhance grain processing by efficiently removing impurities like dust, sand, and so...

Grain sifter for milling applications

Optimize your grain processing by efficiently sifting and sorting a variety of produc...

Industrial sieving solution for powders and granulates

Ensure top sanitation and food safety in your production line with...

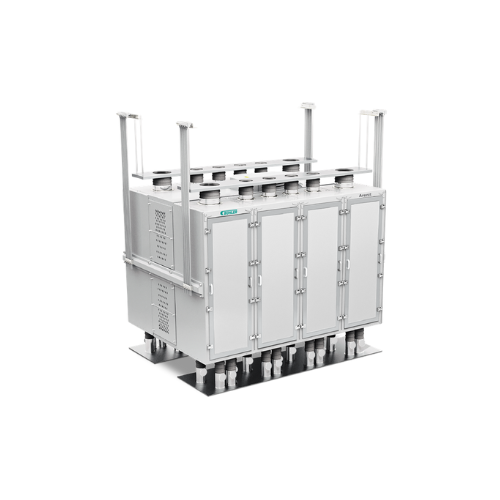

Industrial grain plansifter

Streamline your milling process with high-capacity sifting and grading for grains, ensuring prec...

Optical sorter for coffee beans

Achieve precise color differentiation and advanced foreign matter detection, optimizing your...

Grain purifier for wheat and corn milling

Optimize grain processing with a high-throughput purifier designed to enhance pu...

Scraped surface heat exchanger for viscous liquids

Optimize heating and cooling of viscous liquids efficiently with conti...

Hammer mill for fine grinding in food and feed industries

Achieve exceptionally fine particle-size distribution with a h...

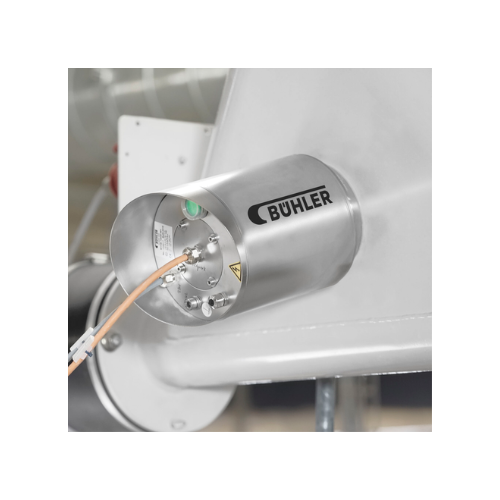

Real-time quality analyzer for flour and semolina

Ensure consistent flour and semolina quality with a cutting-edge online...

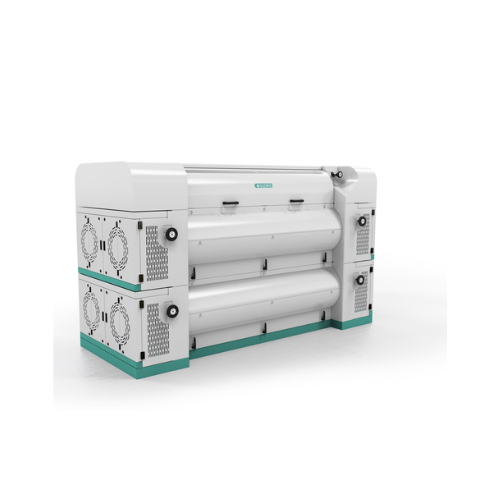

Square plansifter for sifting and sorting flours

Enhance flour production efficiency with this advanced square plansifter,...

Sieve tensioning device for milling applications

Achieve precise and consistent tensioning across various sieve frames wit...

Online color and specks measurement for milling processes

Ensure your milling process consistently delivers top-quality ...

Moisture control system for grain milling

Optimize moisture levels precisely within your grain milling process, ensuring c...

Retentioner for animal feed safety enhancement

Enhance your feed production line with a retention system designed for unif...

Impact machine for milling applications

Optimize your grain processing with this versatile impact machine, designed to refi...

Hydration solutions for baked goods

Achieve consistent dough quality faster with a system that precisely hydrates and mixes...

Laboratory plansifter for particle-size distribution

Optimize your grain milling and brewing operations with precise part...

Horizontal hammer mill for grain processing

Optimize your grinding processes with our horizontal hammer mill, designed to ...

Industrial hammer mill for size reduction in food and feed processing

Achieve precise grinding and milling for diverse ...

High-throughput hammer mill for animal feed production

Ideal for high-throughput operations, this hammer mill ensures pre...

Fully automatic bagging station for granular products

Streamline your packaging line with a high-speed solution designed ...

Automatic bagging station for powdery products

Streamline your packaging line with a reliable solution designed for high-s...

Grainplus screening system for grain quality

Ensure precision in grain cleaning with a compact and efficient sieving techn...

Automatic silo scale for grain processing

Enhance your grain handling operations with precision weighing and dosing, ensur...

Hydrothermal kiln for oats and sorghum

Optimize your grain production with advanced enzyme inactivation and hydrothermal tr...

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Flat storage system for grain

Designed to accommodate various agricultural products, this flat storage system ensures effici...

Four-roller and eight-roller mill for grains

Optimize your grain processing with precise roller configurations, ensuring c...

Discharge station for bags and big bags

Ensure consistent material flow and hygiene in your production line with a versatil...

Grain cleaning drum sieve

Optimize your grain processing with this versatile pre-cleaning solution designed to efficiently r...

Continuous-flow dryer for grain and oilseeds

Streamline your grain and oilseed processes with efficient moisture eliminati...

Enclosed belt conveyor for grain handling

Optimize your material transportation and ensure dust-free operations with this ...

Malt conditioner for optimal brewing efficiency

Enhance your milling process with precise moisture control, ensuring optim...

High-performance cracking mill for oilseeds

Optimize your oilseed processing with a versatile mill designed to enhance eff...

Cracking mill for oilseeds and feed

Enhance your production efficiency with a cracking mill that optimizes throughput and m...

Optical sorter for grain and seed sorting

Ensure precise defect detection and efficient sorting of grains, pulses, and see...

Efficient destoner for wheat and rye

Achieve optimal grain purity with a high-speed destoning solution that efficiently rem...

Weighing and receiving container for floury products

Achieve precise and consistent ingredient proportions with this syst...

Bran finisher for wheat and rye

Enhance your milling efficiency by separating finer flour from bran with ease. This compact ...

Optical sorter for wheat applications

Effortlessly enhance product purity by eliminating color defects and foreign material...

Soybean dehulling separator

Enhance the quality of your oilseeds and grains by efficiently separating hulls and impurities, ...

Integrated grinding system for wheat and grain

Optimize your grinding process with a system that delivers consistent parti...

Tubular screw conveyor for grain transport

Efficiently discharge and dose raw materials with high precision, ensuring seam...

Industrial grain cleaner

Improve grain quality while cutting energy costs significantly with a high-throughput grain cleaner ...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Fluid-bed toaster for cereal processing

Achieve precise control over texture and taste while reducing operating costs with ...

Air-recycling aspiration channel for grain cleaning

Optimize grain processing with an innovative air-recycling system tha...

Flour sifting and sorting solution for grain mills

Optimize your milling operations with efficient sifting and sorting te...

Grain purifier for high-yield flour and semolina

Optimize your milling process with advanced purification and grading, ens...

Square plansifter for flour and semolina rebolting

Achieve superior flour and semolina quality by efficiently sifting and...

Grain product plansifter

Optimize your grain processing with a magnetic drive plansifter that efficiently sifts and sorts a d...

Industrial plansifter for grain sifting and grading

Optimize your production line with precision grain separation, mainta...

Chain conveyor for grain handling

Optimize your production line with a customizable chain conveyor that ensures efficient, ...

Trough screw conveyor for transporting grains

Efficiently transport and handle bulk materials like grains and flour with r...

Bran finisher for efficient flour and bran separation

Optimize your grain processing efficiency with a solution designed ...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

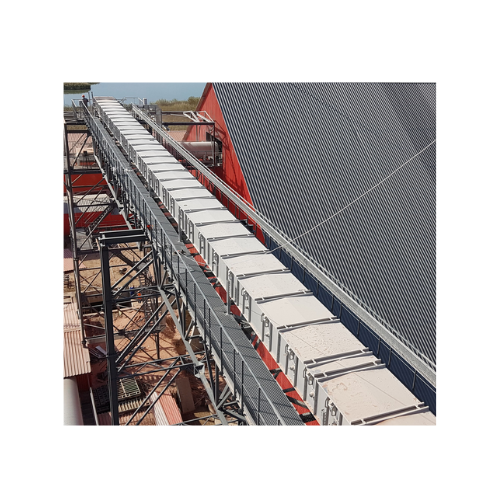

High-capacity horizontal conveyor for bulk storage

Optimize your high-speed bulk material handling with a durable and eff...

Laboratory plansifter for grain milling and brewing

Achieve precise particle-size distribution and quality control across...

Integrated grinder for wheat and grain

Achieve superior grinding performance and energy efficiency with this fully integrat...

Air cleaners for grain dust removal

Enhance safety and operational efficiency by effectively removing dust and light partic...

Small plansifter for grain milling

Optimize your grain milling with a compact plansifter designed for high-speed, precise s...

Vertical grain conveying solution for animal feed and bulk materials

Efficiently transport and elevate various bulk mat...

Bran finisher for flour milling

Enhancing your milling process, this solution boosts flour yields by efficiently separating ...

Standard starch viscometer for gelatinization analysis

Ensure precise gelatinization property measurement with real-time ...

Digital torque viscometer for starch analysis

Experience rapid and precise starch gelatinization analysis with a compact, ...

Coffee roasting system

Optimize your coffee production from green beans to finely ground espresso with this versatile system,...

Flour handling plant for pasta production

Streamline your production with precision handling and processing of flour for p...

Material handling system for confectionery production

Optimize your production line with a system designed for efficient ...

Laboratory grain milling system

Achieve precise grain milling and sample preparation with high-speed capability and gentle t...

Moisture analyzer for flour and tobacco

Optimize your moisture measurement process with precision and speed, ensuring quali...

Extensograph for assessing dough rheology

Optimize dough quality with precise rheological analysis, ensuring your baking p...

Gluten-free flour mixing solution

Ensure consistent dough quality and precise analysis in gluten-free production with a rob...

Flour and dough analyzer

Enhance your dough and flour testing with precise rheological analysis, ensuring optimal water absor...

Gluten quality testing solution

Ensure optimal flour quality by rapidly assessing gluten properties, allowing you to refine ...

Measuring mixer for small grain samples

Optimize the precision of your formulation processes with a solution designed for p...

Measuring mixer for flour and dough analysis

Optimize your dough consistency and quality with precise mixing and kneading ...

Measuring mixer for flour farinograph tests

Achieve precise dough consistency with ease—this mixer ensures reliable testin...

Bran duster for flour yield and ash content optimization

Enhance your milling efficiency by optimizing flour yield and pr...

Industrial sample preparation mill

Ensure precise moisture, protein, and fat content analysis with this reliable milling so...

Flour and dough analyzer for quality control

Ensure precise flour and dough quality analysis with dependable standards com...

Standard flour viscometer

Ensure your baked goods meet the highest quality standards with precise starch and enzyme activity...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

Integrated pickup station for bagged products and big bags

Streamline the handling and transition of bulk materials with...

Modular big bag discharge station for bulk material handling

Streamline your bulk material handling with a customizable ...

Dust-free docking collar for containers and bins

Achieve seamless, dust-free connections between containers and processing...

Bag feeding hopper for bulk solids

Optimize your material handling with a robust feeding hopper that seamlessly integrates ...

Dust-free big bag connection system for bulk solids

Eliminate dust and ensure reliable discharge with this vacuum docking...

Industrial checkweighers for medium-large products

Manage large and heavy packagings with precision and efficiency, ensur...

Mill sifter for precise bulk density and particle size distribution

Achieve precise particle size and uniform bulk dens...

Paddle dryer for industrial sludge

Achieve consistent drying and pasteurization of complex materials with this advanced pad...

Volumetric filler for bags and rigid containers

Optimize precision filling of powders and granules with a versatile soluti...

Multi-fill powder filling system

Achieve precise and consistent filling for your powdered and granulated products with a mod...

Tumbler screening for fine and ultra-fine sieving

For operations demanding precise particle separation, this solution off...

In-line filling system for various container sizes

Streamline your production with versatile in-line filling solutions th...

Industrial auger sack filler for large bags

Designed to efficiently fill large bags and sacks, this advanced filling machi...

Vertical form fill seal filling system for auger applications

Effortlessly integrate precise powder and granule filling ...

Industrial bagging system for high-speed processing

Optimize your packaging line with this engineered-to-order bagging sy...

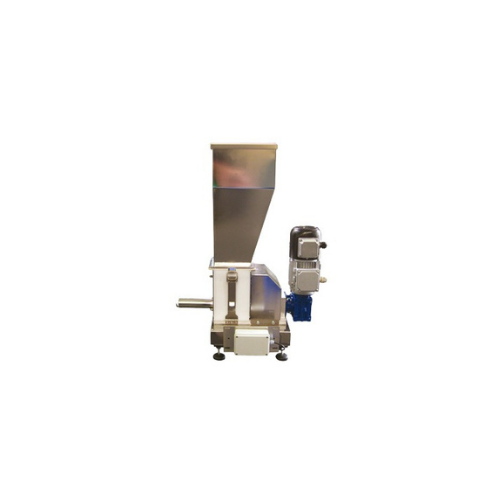

Breader for flour and free-flowing coating materials

Efficiently apply even coatings on a variety of food products, from ...

Electric breading applicator for high-volume food production

Enhance coating precision and ensure dust containment with ...

Flour and crumb feeders for breading and pre-dusting processes

Optimize your breading and pre-dusting operations with ad...

Cyclone filter for pneumatic conveying systems

Efficiently separate and filter airborne dust in pneumatic conveying lines,...

Self-cleaning silo filter

Ensure purity and compliance by trapping dust effectively during silo loading, while maintaining c...

Square sieve for removing foreign bodies and grain sizes

Achieve precise material separation and enhance product purity w...

Industrial vibrating extractor for homogeneous product conveyance

Ensure consistent flow of dry bulk materials with a v...

Loading box for granular products in production lines

Optimize your production line with a manual-to-continuous loading b...

Scrap grinding system for reprocessing dry pasta

Efficiently reprocess dry pasta into reusable flour and dough, minimizing...

Storage silos for granular products

Enhance storage efficiency and flexibility with modular silos, ensuring precise monitor...

Big bag emptying station for bulk product handling

Streamline your bulk material handling with a station designed to effi...

Finished product storage silos for industrial applications

Optimize your storage capabilities with silos that ensure saf...

Vibrating extractor for silo and hopper product distribution

Ensure consistent product flow and precise distribution fro...

Big bag emptying station for raw materials

Streamline your material handling process by efficiently lifting, emptying, and...

Big bag loading station for bulk product handling

Efficiently manage big bag handling with a system that combines hoistin...

Lean phase pressure conveying for powder handling

Effortlessly transport and manage powdered materials with lean phase pr...

Vacuum powder sampler for particle size distribution control

Ensure precise quality control with a vacuum powder sampler...

Bulk storage silos for food products

Ensure optimal powder storage and handling with versatile silos designed for efficient...

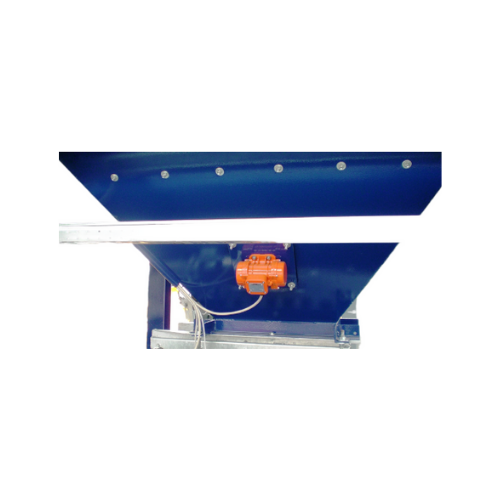

Vibration table for food, feed, and chemical industries

Optimize your production line with a versatile vibration table de...

Continuous motion packaging for short-cut pasta

Optimize your packing line with a high-speed solution designed for efficie...

Dust-free flour applicator for food coating

Eliminate dust from your coating process with precise flour application, ensur...

Low care bulk powder fillers

Optimize your production efficiency by accurately filling flexible bulk containers with dry pow...

Plastic bag sealer for polyethylene bags

Achieve consistent hermetic sealing of polyethylene bags while preserving the inte...

Semi-automatic powder filling system for food products

Achieve precise and flexible filling for food powders and granules...

Industrial powder fillers for various containers

Optimize your packaging line with high-speed powder fillers that handle d...

Cyclone separator for pneumatic conveyor systems

Enhance efficiency in pneumatic conveyor systems by effectively separatin...

Pneumatic conveying diverter valve for abrasive bulk materials

Streamline the flow of abrasive materials in your pneumat...

Industrial rotary sifter for bulk materials

Ensure precision and quality in your production line with a robust solution de...

Rotary sifter for bulk material separation

Eliminate foreign particles and ensure precise grain size verification with a h...

Pneumatic conveying systems diverter valve

Effortlessly manage bulk material flow with precision, ensuring seamless transi...

Rotary sifter for bulk material preparation

Ensure precise material preparation and protect downstream processes by integr...

Pneumatic mixer for fluidizable bulk materials

Achieve uniform and gentle mixing of powdered ingredients with minimal effo...

Industrial fine dust particle ventilation filter

Optimize your production line with a modular filtration system designed t...

Dosing and conveying screw for dry bulk materials

Efficiently manage the precise dosing and conveying of dry, powder, and...

Bin vent filter for dust control in modular systems

Optimize your production line by efficiently controlling dust and fin...

Rotary feeder for powdered bulk materials

Achieve precise control in feeding and discharging powdered materials with a rot...

Fluidizing bed for bulk material discharge

Optimize your material flow with a fluidizing bed designed for seamless dischar...

Fluidizing bed blending silo for powder mixing

Optimize your batch mixing process with a fluidizing bed blending silo, des...

High-pressure rotary feeder for powder and agglomerates

Optimize your production line with a high-torque solution that ef...

High-pressure rotary feeder for bulk material handling

Manage high-pressure bulk material distribution with precision, en...

A-type rotary feeder for powder and pelleted bulk materials

Ensure precise feeding and discharging of powdered and pelle...

High performance spiral mixer for dough preparation

Achieve consistent dough quality with ease by integrating a high-perf...

Automatic dough mixing system for high-quality doughs

Transform your dough production with a system designed for rapid, c...

Mixing system for long dough resting times

Achieve consistent dough quality with extended resting times, optimizing water ...

Linear mixing system for high-capacity dough production

Achieve perfect dough consistency with precise mixing, rapid cycl...

Continuous tunnel oven for panettone baking

Optimize your bakery production with a modular tunnel oven that integrates sea...

Dough divider for various dough types

Achieve precise portioning in your dough production with a solution designed to handl...

Weight accurate dough divider for various dough types

Achieve high-speed, precise dough portioning with adjustable pressu...

Dough divider for varied dough types

Achieve precise and consistent dough portioning with a single pocket divider designed ...

Industrial dough proofer for high-capacity baking lines

Optimize your baking process with high-speed proofing, ensuring d...

Intermediate proofer for dough processing

Enhance your dough production process with efficient proofing solutions that ens...

Industrial long moulder for pan and hearth bread

Enhance your bread production with precise sheeting and curling that impr...

Single-shaft ribbon blender for homogeneous mixing

Achieve high-quality, precise blending of delicate and temperature-sen...

Tanker loading bellow for dust-free bulk solids loading

Optimize tanker loading while minimizing dust emissions with this...

Bulk solids conveying systems

Efficiently move and manage bulk materials with precision and reliability, ensuring seamless i...

Bulk solids discharging and loading solution

Optimize your bulk material handling with equipment that ensures efficient an...

Pneumatic conveying system for bulk solids

Ensure efficient and dust-free transport of bulk materials with a pneumatic con...

Batch-type single shaft mixer for industrial mixing

Achieve precise and uniform mixing with high-speed, single-shaft mixe...

Butterfly valves for dry powder and granule flow interception

Ensure precise control over material flow in your processi...

Atex-certified flanged polygonal dust collectors

Ensure dust control and compliance in explosive environments with our com...

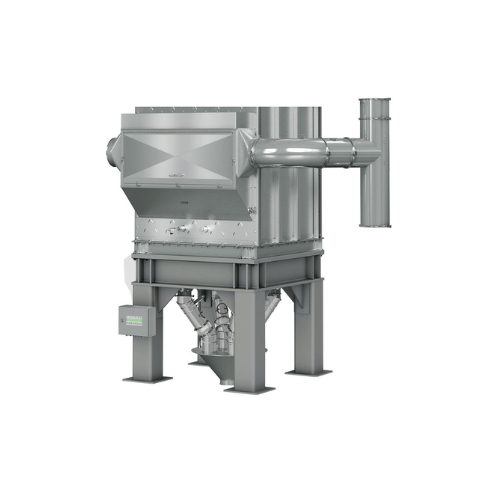

Industrial dust collection system for air filtration

Optimize air quality in your production line with this compact dust ...

Atex certified flanged round dust collectors

Designed for potentially explosive environments, these flanged round dust col...

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to ma...

Flanged round dust collectors for industrial air filtration

Optimize your industrial processes with a dust collection sy...

Fit-frame butterfly valves for dry bulk solids

Achieve precise control and minimize contamination in your dry bulk materia...

Butterfly valves for powders and granules

Ensure precise flow control and reliable sealing for gravity-fed or pneumatic sy...

Butterfly valves for powder and granular material handling

Experience seamless material control with advanced butterfly ...

Industrial slide valve for heavy-duty applications

When managing gravity material flow in abrasive environments, achievin...

Low profile slide valve for controlling powder flow

Optimize your powder and granule flow management with precision-engin...

Slide valves for flow interception in powder and granular materials

Effectively manage the flow of powdery and granular...

Tapered single shaft screw feeder for flour mills

Ensure consistent material flow and minimal residue with this precise s...

Diverter valves for pneumatic conveying lines

Experience precise flow control in pneumatic conveying with diverter valves ...

Drum-type diverter valves for pneumatic conveying

Optimize your pneumatic conveying system by effortlessly controlling th...

Vibro-aerators for bulk solids discharging

Optimize your powder flow and ensure consistent discharge with this advanced ae...

Spring-loaded pressure relief valves for silo overfill protection

Ensure safety and prevent costly overfills with press...

Stainless steel tubular screw conveyor for bulk solids handling

Ensure precise material handling with stainless steel tu...

Single shaft screw feeders for consistent material feeding

Tackle challenging materials with poor flow characteristics b...

Drop-through rotary valve for powder and granular material feeding

Achieve precise control in discharging and feeding p...

Blow-through rotary valves for pneumatic conveying

Optimize your pneumatic conveying systems with high-efficiency blow-th...

Rotary ball vibrators for aggregate reclaiming

Enhance efficiency in your production line with a solution that optimizes t...

Manual bag opener for bulk solids discharging

Effortlessly open and empty bags while containing dust emissions, ensuring a...

Single impact pneumatic hammers for flow aids

Combat material clogs and ensure smooth flow in your production line with pn...

Pneumatic hammers for bulk solids discharging

Optimize your production efficiency and solve material flow challenges with ...

Pneumatic hammers for aiding material flow

Optimize material flow and eliminate blockages in your processing line with pne...

Industrial vibrator for high-frequency vibration

Achieve efficient material flow and compaction across various production ...

Rotary turbine vibrators for bulk solids discharging

Enhance the efficiency of material handling with high-speed, low-noi...

Rotary turbine vibrators for material flow aid

Optimize your production efficiency with high-speed, silent operation vibra...

Continuous impact vibrators for bulk material removal

Combat material flow issues like bridging and rat-holing with our i...

Continuous impact vibrator for aggregate reclaiming

Tackle material flow challenges head-on by preventing common issues l...

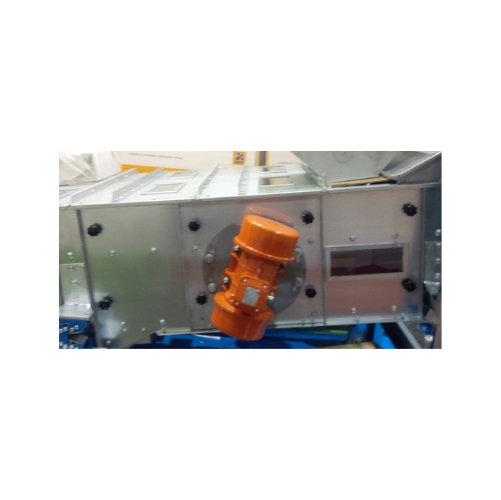

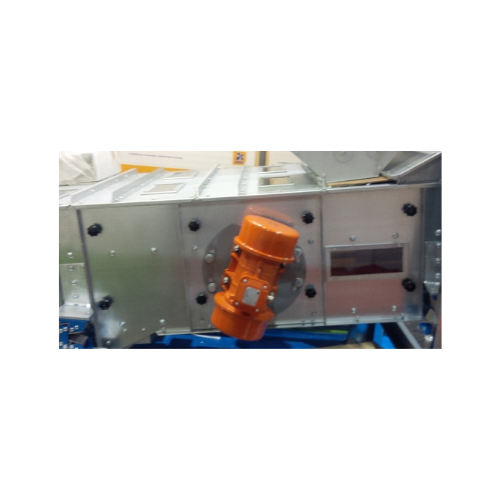

Electric motovibrators for flour milling sieving

Enhance precision in your milling operations with motovibrators that deli...

External electric motovibrators for efficient flour sieving

Optimize material flow in your milling operations with preci...

Live bin bottom for difficult material discharge

Efficiently manage the discharge of challenging materials like biological...

External electric motovibrators for bulk solids conveying

Enhance material flow efficiency and solve challenging dischar...

Industrial electric vibrator for bulk solids discharging

Enhance material flow efficiency and ensure consistent output ac...

External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material disc...

External electric motovibrators for hazardous materials

Ensure safety and efficiency in hazardous environments with relia...

Micro-batch feeders for powder and granular material

Struggling with clog-prone powders? Gain precise control and consist...

High efficiency micro-batch feeder for powdery or granular materials

Achieve precise volumetric feeding and metering of...

Trough screw conveyor for flour mills

Optimize your flour processing with efficient material handling, precisely designed f...

Aeration pads for powdery material flow in silos

Ensure consistent material flow in your silos and bins with a reliable ae...

Bin level indicator for bulk solids

Ensure precise material level detection across your production processes, minimizing th...

Bin level indicators for wastewater treatment

Ensure reliable material level monitoring in your silos and hoppers with ILT...

Bin level indicators for powder and granular material

Ensure precise inventory management and prevent overflows in your p...

Pipe couplings for pneumatic conveying lines

Ensure a secure and quick connection for your pneumatic lines with these pipe...

Electric gear motor actuators for slide valves

Achieve precise control over industrial slide valves in high-speed operatio...

Stainless steel trough screw conveyor

Ideal for precise handling of powdery and granular materials, this solution ensures m...

Loss-in-weight screw feeder for precise powder dosing

Achieve high precision in continuous dosing with this advanced scre...

High capacity vertical conveying for grains and cereals

Ensure efficient vertical transport of bulk materials like cereal...

High capacity vertical conveying for flour

For consistent, high-speed handling of delicate and powdery materials, this eng...

Waste bag compactor for bulk solids

Efficiently compact waste bags to a fraction of their volume, streamlining disposal whi...

Vibratory outlet hopper for bulk material discharge

Struggling with material bridging and inconsistent discharge? Enhance...

Industrial bin activator for smooth material flow

Enhance your material handling process with a solution that ensures con...

Rotary bin discharger for bulk solids

Efficiently manage bulk solids with a rotary bin discharger that minimizes residue an...

Tapered twin shaft screw feeders for bulk solids

Ensure consistent flow and avoid material bridging challenges with a solu...

Tubular trough screw conveyors for gentle powder and granular material handling

Achieve precise powder and granular ma...

Vibratory hopper for bulk solids discharge

Ensure consistent material flow and prevent bridging in storage silos with this...

Bin activator for silo and hopper discharge

Ensure optimal material flow and prevent blockages in your storage systems wit...

Vibratory outlet hopper for bulk solids discharge

Reduce material handling challenges with highly efficient vibration tec...

Powder locks for safe bulk material handling

Ensure containment and prevent contamination while processing sensitive bulk ...

Powder handling vacuum conveyor system

Streamline your material transfer with a versatile vacuum conveyor system that ensur...

Big-bag unloading station for bulk materials

Facilitate seamless integration into your production line with efficient bulk...

Rotary pouch packaging system for food and powder products

Streamline your packaging process with a rotary system that e...

Vertical form fill seal for large bag packaging

For operations requiring precise, large bag packaging, this equipment ensu...

Vertical form fill seal for bulk bag packaging

Streamline your bulk bag packaging with efficiency and precision, ideal for...

Industrial printers and labelers for packaging

Ensure precise package identification and traceability with robust printing...

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Flash dryer for corn starch

Reduce energy consumption and maintain product quality with efficient drying solutions designed ...

Wheat processing systems for industrial applications

Maximize efficiency in wheat processing with a system designed for p...

Baking form storage system

Optimize your production line with efficient and flexible baking form storage and buffering, ensu...

Vertical packaging system for medium-high speed applications

Optimize your packaging line with a system that delivers pr...

Vibro bran finisher for milling operations

Optimize your grain processing with an advanced vibratory system designed to en...

Screw conveyor for grain or finished products

Optimize your production line with a space-efficient screw conveyor designed...

Vitamin adding system for ground products

Ensure precise vitamin dosing in continuous production lines, enhancing nutritio...

Chain conveyor for horizontal transportation

Efficiently handle diverse materials with a reliable chain conveyor, designed...

Industrial drum detacher for semolina and bran separation

Achieve precise separation of semolina and bran with minimal e...

Flowmeter for precise wheat measurement

Ensure consistent product quality and optimize flow control with precise measuremen...

Conveyor system for packaged product transportation

Efficiently streamline the movement of your packaged goods with a rob...

Industrial roller mill for high-stability milling

Optimize your milling process with a high-speed roller system designed ...

Double deck roller mill for grain milling

Achieve superior milling results with increased efficiency and hygiene in proces...

Tube screw conveyor for flour and fine-milled materials

Optimize your production line by efficiently transporting flour a...

Turbo sifter for milling processes

Optimize your milling efficiency with a high-speed turbo sifter designed to precisely se...

Flour distribution system

Efficiently streamline the regulation and distribution of flours within your production line, ensu...

Flour screw conveyor for horizontal transport

Efficiently transport milled products horizontally with our innovative screw...

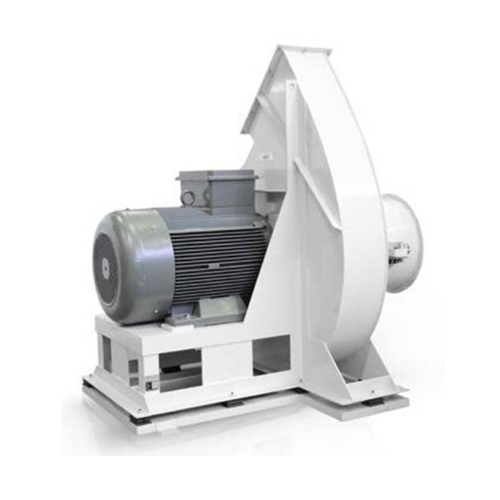

Pneumatic fan for milling industry applications

Effortlessly reduce noise and vibration while optimizing energy use in gra...

Pneumatic cyclone for effective product-air separation

Optimize particle separation with high-speed pneumatic cyclones, e...

Pneumatic diverting valve for powder and granule transfer

Efficiently redirect bulk materials from one point to another ...

Industrial semolina purifier

Enhance your grain processing with high-capacity semolina purification, ensuring efficient clea...

Separation system for low-density materials from grains

Efficiently separate lightweight impurities from dense grains to ...

Industrial extraction scale for accurate material weighing

Ensure precise ingredient proportions in your milling operati...

Grain separator for removing foreign materials

Ensure high-quality grain processing by efficiently removing foreign materi...

Silo discharger for freely flowing materials

Optimize your material flow and prevent bottlenecks with a highly efficient s...

Automated grain blending system

Achieve precise blending ratios for grains and seeds, streamlining your production line by a...

Automatic packaging machine for open-mouth bags

Optimize your packaging line with precision weighing and high-speed baggin...

Automatic dampening system for wheat moisture regulation

Enhance your milling efficiency by precisely controlling wheat m...

Blending machine for pre-grinding or tempering processes

Optimize your grain processing with precise blending and mixing ...

Horizontal wheat transport conveyor

Efficiently transport grains horizontally without breakage while maintaining product in...

Square plansifter for grain milling

Achieve precise grain separation and enhanced purity levels with this high-performance ...

High capacity carousel packaging solution

For high-capacity milling operations, this packaging solution minimizes labor an...

Bran finisher for flour mills

Enhance your milling efficiency by effectively separating flour particles from bran, ensuring ...

Industrial grain control plansifter

Ensure precise grain quality control with an advanced plansifter, essential for guarant...

Bucket elevator for grain and powder products

Efficiently transport bulk materials like grain and powder vertically with p...

Industrial heavy particle separator for wheat cleaning

Optimize the performance of your filtration systems by interceptin...

Maize flour and semolina milling solution

Efficiently transform corn into diverse food products by combining precision cle...

Ecluse for pneumatic conveying systems

Ensure seamless and leak-free material flow in continuous and high-speed operations ...

Flour insect control system

Eliminate pest contamination and preserve flour quality with high-speed larva destruction, ensur...

Square plansifter for flour production

Optimize your flour milling process with enhanced sifting and classification, ensuri...

Industrial airlock for pneumatic systems

Ensure precise air and product separation in your pneumatic systems, maintaining m...

Industrial impact detacher for semolina processing

Optimize your grain processing line with a solution designed to enhanc...

Semolina purifier for milling operations

Achieve precise separation and classification of semolina and bran with this purif...

Jet filter for industrial air purification

For facilities grappling with dust and pollutant control, enhancing air quality...

Horizontal scourer for flour and semolina mills

Achieve efficient grain cleaning by removing hulls and contaminants seamle...

Industrial hammer mill for food industry grinding

Efficiently reduce raw material size with high-speed precision grinding...

Double story paddy sieve for rice cleaning

Efficiently cleanse and separate impurities from rice, lentils, and grains, ens...

High capacity grain sifter

Efficiently separate and clean a variety of grain types with minimal space requirements, ensuring...

Classifier for flour, semolina, and pulse factories

Optimize grain processing with a high-capacity classification solutio...

Hammer mill feeder for controlled grain processing

Optimize your feed production line with precise material control, redu...

Inclined intensive dampener for grain processing

Ensure consistent moisture levels for optimal grain processing and enhanc...

Low pressure fan for grain cleaning

Optimize your grain processing with our low pressure fan, effectively classifying and c...

Blower for vertical and horizontal grain transport

Efficiently transport grains, legumes, and flour both vertically and h...

Intensive dampening system for flour mills

Enhance grain quality and moisture control with a high-speed solution that mini...

Vibratory storage hopper with inclined screw conveyor

Enhance your production line efficiency with a vibratory storage ho...

Volumetric auger filler for powder packaging

Streamline your powder packaging process with precise and efficient volumetri...

Volumetric auger filler for precise powder weighing

Optimize your production line with a high-speed volumetric auger fill...

Volumetric auger for powder weighing and depositing

Ensure precise powder weighing and depositing for consistent product ...

Sachet powder filling machine

Optimize your packaging line with this efficient solution for precise powder filling, ensuring...

Gravimetric auger filler for powder weighing

Achieve precise powder filling with this gravimetric auger solution, ensuring...

Bag tipping unit for Cip processes in powder handling

Ensure seamless powder handling and high hygiene standards in your ...

Autonomous ingredient dissolver for high-volume dry ingredient mixing

Efficiently mix multiple high volumes of dry ingr...

Continuous fluid bed dryers for various industrial applications

Achieve precise moisture control with fluid bed dryers, ...

Ventilation and dehumidification for meat processing plants

Achieve precise humidity and condensation control in meat pr...

Dry ingredient blending solution for confectionery and bakery products

Achieve seamless integration of dry inclusions i...

Automated ingredient weighing and dosing system

Streamline your production process with precise and consistent ingredient ...

Chili powder milling machine

Transform raw spices into finely milled powders effortlessly with this high-speed grinding solu...

Cassava crusher for efficient starch processing

Optimize your cassava and grain processing with this robust crusher, desig...

Spice and pharmaceutical powder grinder

Efficiently transform raw materials into fine powders, ensuring optimal consistency...

Pneumatic inline sifter for dry flowing material

Ensure precise particle segregation and foreign matter removal with this ...

High-capacity industrial sifter for chemical and food processing

Achieve unparalleled screening precision and efficiency...

Accu-feed system for dry material separation

Boost efficiency by combining storage, feeding, and screening into one space-...

Round vibratory separation for high capacity screening

Maximize screening efficiency with dual screen vibratory technolog...

Dough cup elevator for bakeries

Effortlessly transport and elevate dough pieces with precision to optimize your bread produc...

Industrial bread production line

Optimize your dough processing workflow with this robust system designed to streamline high...

Thermal conditioning for improved meal flow and starch digestibility

Ensure optimal meal flow and starch digestibility ...

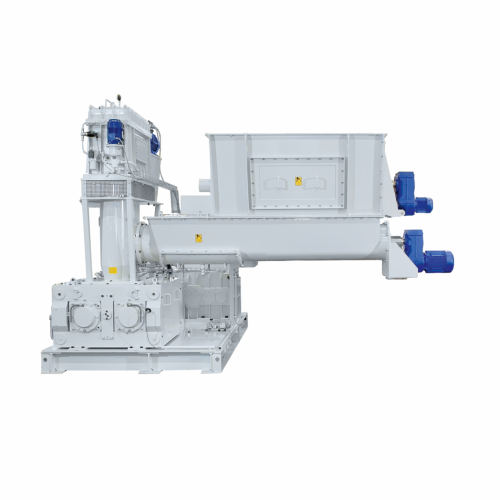

Twin shaft paddle mixer for bulk materials

Achieve precise blend consistency with a twin shaft paddle mixer designed to ha...

Conical dough rounder for perfectly round dough balls

Achieve impeccable dough rounding with precision-engineered technol...

Continuous mixer for accurate ingredient blending

Achieve precise mixing in continuous production with optimal control ov...

Dosing screw system for precise ingredient management

Achieve unparalleled precision in formulating mixtures with our dos...

Pellet mill for powdery product processing

Transform powdery materials into durable pellets with precision and efficiency,...

Small batch mixing rotosphere blender for food industry

Achieve precise mixing of small batch powders and granules with a...

High-capacity pre-cleaner drum for grain silo storage

Optimize your pre-cleaning process with a high-capacity drum that e...

Industrial hammermill for fine grinding applications

Elevate your milling efficiency with hammermills designed for precis...

High-capacity sleeve filters for silo dedusting

Optimize your production with filtration systems that ensure efficient dus...

Pellet mill conditioner for optimal granulation

Enhance pellet quality and efficiency by seamlessly integrating steam mixi...

Pellet mill for powdery animal feed products

Maximize plant efficiency and product quality with a versatile pelleting solu...

Agricultural cleaner-separator for grain processing

Optimize your grain processing with a versatile cleaner-separator eng...

Stationary drying system for agricultural products

Optimize moisture control and energy efficiency in your drying process...

Stationary grain dryer with exhaust air system

Optimize your drying process with a system designed to handle diverse mater...

High-force texture analyser for precise measurement

Achieve unparalleled precision in texture analysis for high-force app...

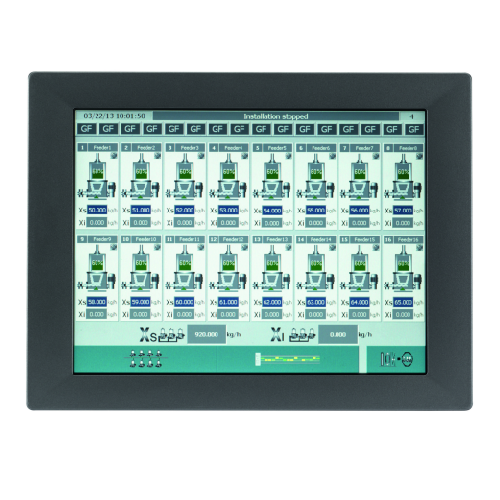

Gravimetric feeder operator interface

Efficiently manage up to 16 gravimetric feeders with a user-friendly interface, enabl...

Metal detection system for powders & granules

Ensure product integrity and protect your machinery from metallic contaminan...

In-line metal detector for liquids & pastes

Ensure product safety by seamlessly integrating a metal detection system into ...

In-line metal detector for pneumatic systems

Ensure product purity and operational efficiency with a solution that effecti...

Conveyor belt metal detection system

Ensure seamless product safety with a system that detects and separates metallic conta...

Metal detector systems for conveyor belts and chutes

Ensure the integrity of your production line by efficiently detectin...

Sanitary modular bulk silos for efficient storage

Maximize your storage capacity and streamline assembly with a modular s...

Modular bulk storage bins for efficient material handling

Maximize your storage efficiency with bolt-together solutions ...

Mass flow rate feeder for bulk powders

Achieve precise control and consistent material flow in high-speed manufacturing env...

Coriolis mass flow meter for powdered materials

Achieve precise continuous feeding and control of bulk solids like cement ...

Bulk reception solution for industrial material handling

Optimize your operations with an above-ground bulk reception sys...

Industrial belt and bucket elevators

Optimize your material handling with elevators designed for high-speed conveying and e...

Bread topping system for consistent seed and flour application

Achieve precise topping consistency with our system, desi...

Industrial storage silos for food ingredients

Optimize your food processing operation with robust storage solutions that s...

Horizontal cartoner for food products

Depending on the primary product packages, food products like confectionery (biscuits...

Washing cabinet for food bulk containers

With an ever-increasing demand for output and stricter hygiene regulations for foo...

Tunnel washer for food containers

With an increase in demand for production across food service and manufacturing companies...

Milling and drying machine for fine powders

When you need to produce ultra-fine powders, the milling and drying process em...

Hygienic floor scale

The food and pharmaceutical industries require maintaining high levels of sanitations as well as logisti...

Open mouth bagging machine

If you are a manufacturer of fertilizers, bulk chemicals, sugar, seeds, or any grains it is likel...

Open mouth bag filling machine for powders

The packaging of powdery products such as flour can be challenging as it is cru...

High capacity grading sieve

An industrial vibratory separator machine is multi-purpose, able to carry out a variety of diffe...

Metal detector for granulated products

Free-fall applications, such us flour, sugar, spices and other granulated or powdere...

ATEX Indoor silo for sugar and flour

Storing granulated or powdered materials such as sugar and flour prior to processing r...

Continuous vertical cartoner

When producing cereals, it is paramount to stay on top of market trends. New packaging forms ca...

Tumbler sieve for classifying and dedusting granular materials

For the classification of delicate granular material, scr...

High volume particles separation sieve

For large scale production processes in the chemicals or food industries that requir...

Multifrequency sieve for separation of difficult particles

Separating particles in difficult-to-process materials for pr...

Two-way flap type diverter valve

Routing powder, pellets or granules from a product source to two receiving points must be d...

Open-mouth baggers for free flowing powders

For bagging free flowing materials into open mouth bags, this system is ideal....

Open-mouth bagging carousel for flour

When you need a carousel for packing powdery bulk materials, the bagging carousel tha...

Manual bagger with gross weigher

This is a manual bagging set with an electronic gross weighing system to meet international...