Making Feed Premixes

Find innovative production technology for making feed premixes and connect directly with world-leading specialists

Feed premix delivers a quality blend of macro and micronutrients to meet the overall growth and health needs of animals. Although they constitute a small portion of the feed, they provide enormous benefits by adding a balanced, nutrient-rich feed that supports the animal health. Feed premix making equipment ensures a proper combination of important ingredients to generate a perfect blend.

Select your feed premixes process

Tell us about your production challenge

Nutritional composition of a quality feed premix

Feed premixes can be micro or macro premixes. While the former constitutes between 0.2-2% of the total animal feed, the latter contributes 2% to 8%. Feed manufacturers consider the original constituents of the main feed before deciding on the type of premix to use. This is to avoid having excessive or less quantity of the essential nutrients. In order to provide safe and beneficial quantities of ingredients to animals, they use a micro-dosing system that ensures precise dosing and weighing of these micro ingredients.

Generally, a feed premix contains essential nutrients like amino acids, vitamins, trace elements, antibiotics, and minerals. However, while making feed premix, producers consider the specific function and needs of the animal. For instance, poultry feed premix should contain essential amino acids like lysine, methionine, tryptophan, threonine, arginine, isoleucine, leucine, histidine, phenylalanine and valine arginine because they are vital for egg production. Cat feeds, on the other should have some of these amino acids but with the inclusion of taurine, which is essential in the development of cats’ vision.

Other important nutrients include vitamin E and selenium, which improves the immune system of chickens, vitamin D and A for bone and visual development, respectively.

Feed premix making equipment for mixing ingredients

In feed premix processing, ingredient composition and size vary significantly. Therefore, producers ensure that a uniform mix is obtained through proper mixing. Manufacturers use horizontal or rotary drum mixers for this step because they can combine raw materials with a wide range of densities. They provide a wide surface area for mixing and generate less friction. These specialized mixers can mix to a low CV (coefficient of variation). The mixing stage occurs in two steps. The first one, micro mixing, is for mixing ingredients that weigh less than a percent of the mixer’s capacity. The second step is the macro mixing, which involves incorporating and blending a carrier such as rice hulls or corn cobs into the premix.

Functions of quality feed premixes

The main purpose of a feed premix is to boost the nutritional content of poultry and livestock feeds. They are not to replace the main feeds but to optimize them to meet the animal’s requirements. They contain growth-stimulants, provide some antibiotic effects, assist animal reproduction and help them develop resistance to infections like Coccidiosis. Feed premix making equipment help manufacturers to obtain and deliver a standard dose for products like antibiotics and vitamins.

Regulation (EC) No 1831/2003 provides crucial guidelines for the manufacturing and use of feed premixes in the European Union. Its goal is to ensure that feed premixes are combined in potent and safe quantities for animals, human handlers, human consumers, and the environment. In the United States, producers should submit a Food Additive Petition for Animal Food (FAP), which contains details of the feed (the ingredients, quantity, animal nutritional benefits and intended duration of use), to the Food and Drug Administration (FDA), which approves the ingredients’ safety for the animals.

Processing steps involved in feed premixes making

Which feed premixes technology do you need?

Double shaft paddle mixers for industrial powders and granulates

Achieve precise mixing and homogenization of dry powder...

Dosing scale for accurate raw material weighing in feed recipes

Ensure precise feed formulation by weighing raw material...

Energy efficient steam dryer for feed products

Traditional drying technologies with low investment cost, such as hot air d...

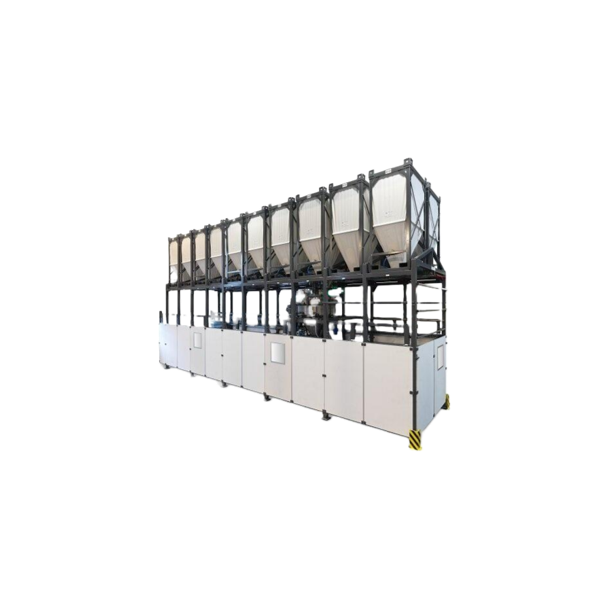

Macro ingredient dosing system

Traditional dosing systems do not have a very long operational life and are hard and expensiv...

Automatic palletizer machine for bags and boxes

The effective placement and positioning of bags and boxes can be a challen...

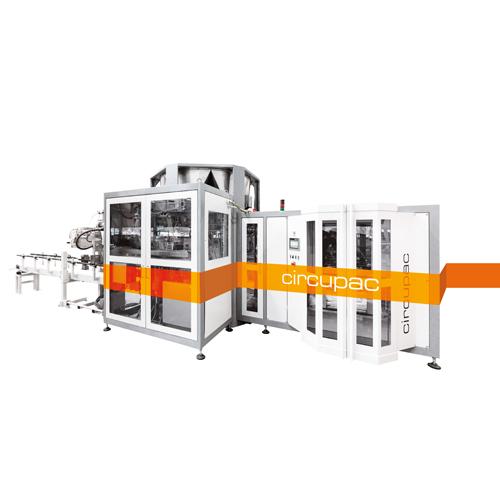

Open mouth bag filling machine for powders

The packaging of powdery products such as flour can be challenging as it is cru...

Automatic bag slitter

Unacceptably high dust levels can be generated whilst manual emptying and handling of bags, also produc...

Rotary bag packers for valve bags

Quick filling of bags while avoiding leakage out of the top of a bag can be challenging o...

Big bag solutions

Management of big bags requires specialist handling and selection of cost-effective configurations for fill...

Hygienic FIBC handling line

There are many considerations when handling FIBC’s (Flexible Intermediate Bulk Containers)...

Big bag discharge system

Dust emissions, product loss and product contamination are the main risks when discharging products ...

Special duty horizontal metering valve

Occasionally, there is no suitable standard valve available for a particular conveyi...

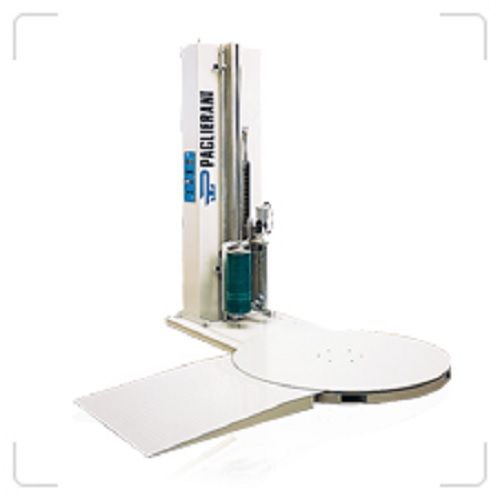

Semi-automatic stretch wrapping machine

At lower speeds, some level of automation is required to provide a cost-effective m...

Traditional palletizer for bags

Packaging lines may require a single, flexible solution that can handle many different palle...

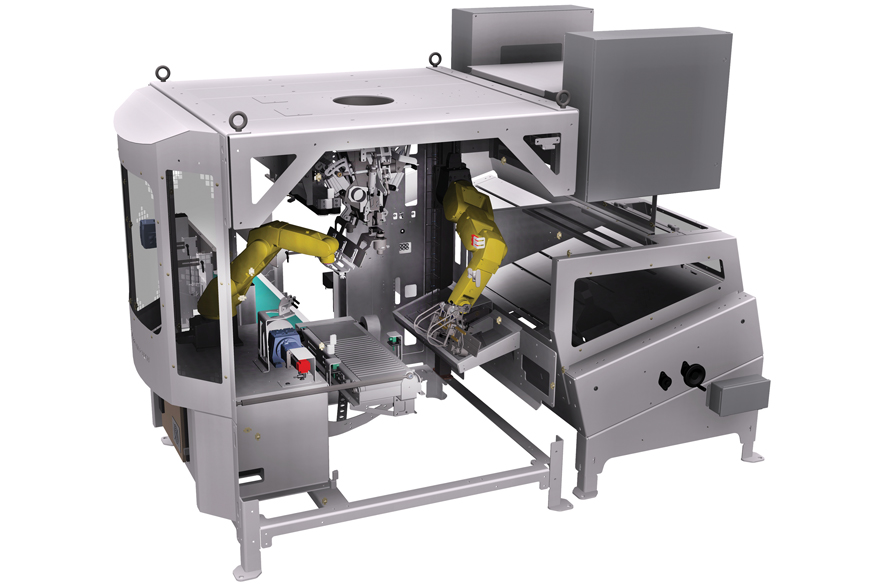

Palletizing robot arm

For high speed palletizing, palletizing high payloads, or just where greater flexibility is required, i...

Hygienic belt dryer

A belt dryer typically applies the product through an infeed chamber onto a perforated horizontal belt, w...

Robot palletizer

Palletize up to 1,800 large industrial bags per hour at a multi-pick-up configuration.

Compact palletizer

Choosing an accurate palletizer can be quite an advantageous move. This one is designed for euro, industri...

Versatile open-mouth bagger

If you want highly precise bagger for bagging multiple bag materials, here you go. This versatil...

Open-mouth baggers for free flowing powders

For bagging free flowing materials into open mouth bags, this system is ideal....

Open-mouth bottom-up baggers

Innovative bottom-up baggers for high-speed industrial packaging will help you create a dust-fr...

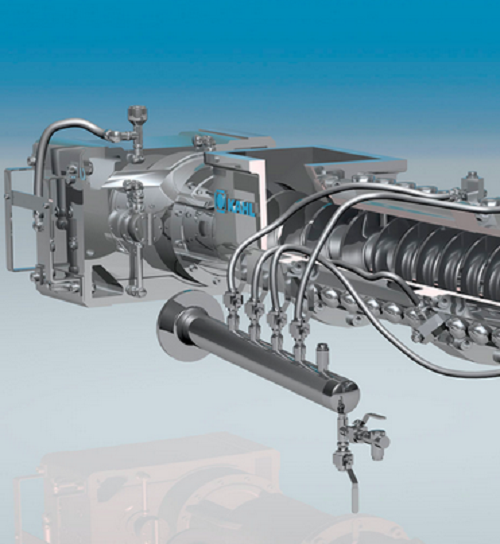

Annular gap expander for compound feed

Compound feed processing often requires a means of kneading and mixing input substra...