Open mouth bag filling machine for powders

The packaging of powdery products such as flour can be challenging as it is crucial to maintain a constant downward airflow which helps direct stray particles into the bag. A state of the art, yet reliable solution is needed which provides high-speed with a continuous motion for the efficient packaging of these products.

Save time with a fast and flexible open-mouth bagging carousel

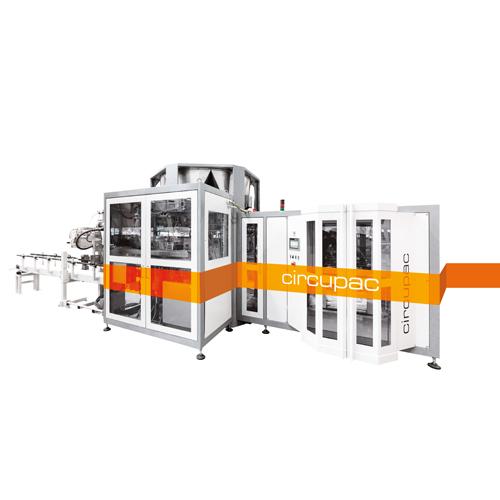

STATEC BINDER’s CIRUPAC is a high-performance bagging carousel which is extremely reliable and accurate. It is specially designed for the packaging of flour and powdery products in pillow bags and gusset bags with a filling weight of 10 kg to 50 kg. It is ideal for filling prefabricated open mouth bags made of woven PP, PE or paper, and can achieve a maximum output of up to 1200 bags per hour.

The Open-mouth bag filling machine for powders is configured with a continuously rotating carousel. The components of the machine are connected to each other with utmost precision to ensure a seamless operation. The prefabricated bags are individually separated from the magazine by vacuum suction and are sent to the pickup station. Upon arrival to the filling spout, the bag is opened and clamped to the filling spout for the filling process. The product is then measured to the specified level and poured into the bag via an intermediate hopper.

At any given time, up to six bags can be filled via the six different filling stations housed in the carousel. The filled bags are transported to the bag sealing station, and during the time of transport the product is continuously compacted by special vibration plates. All these steps take place continuously, thus ensuring a seamless packed bag output. Its applications include powdery products such as flour, animal feed premixes or corn starch, etc.

Benefits

- One master servo motor

- Product compression in the bag

- Continuous rotation

- Compact design