Bin level indicators for wastewater treatment

Ensure reliable material level monitoring in your silos and hoppers with ILT-type indicators designed for precise electric signaling and efficient process integration.

Monitors and Signals Material Levels in Storage Bins

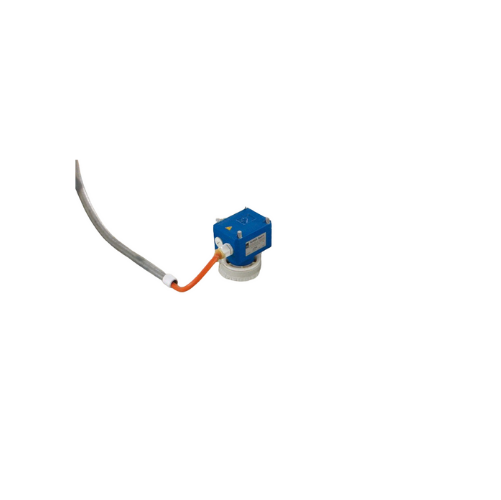

The ILT-type Bin Level Indicators from WAMGROUP offer a reliable solution for efficient level measurement and material monitoring across a range of industries, including construction, food processing, and environmental technology. These rotary level indicators use a mechanical paddle to detect material presence, stopping rotation at maximum fill and restarting when levels decrease. This ensures accurate signaling in applications with varied bulk densities, such as concrete, flour, and plastics.

Built to withstand high process temperatures and available with multivoltage capability, the ILT indicators are adaptable to diverse industrial environments. All contact parts are crafted from stainless steel, providing robust corrosion resistance. Certified under ATEX regulations, these indicators ensure safety when operating in potentially explosive atmospheres.

Integration into your existing systems is straightforward, with options for both top and side installations in bins, hoppers, or silos. Multiple paddle designs allow for precise measurement tailored to specific material characteristics. The ILT indicators emphasize cost-effectiveness and minimal maintenance, supporting continuous operations with enhanced operational safety and efficiency.

Benefits

- Ensures precise inventory control by accurately monitoring material levels.

- Reduces maintenance with durable stainless steel construction and robust design.

- Enhances operational safety with ATEX certification for explosive atmospheres.

- Adapts to varied material densities with versatile paddle designs.

- Simplifies installation and integration with flexible mounting options.

- Applications

- Lime, Asphalt, Building, Sludge treatment, Cosmetics, Drymix building materials, Minerals, Municipal waste water treatment, Cement, Dust filtration, Detergents, Iron and steel, Glass, Flour milling, Brick, Spices, Construction, Lime dosing, Rice milling, Rubber, Precast concrete, Ceramics, Animal feed, Marble, Pet food, Pasta, Noodle, Roof tile, Sugar, Varnish, Biscuit, Fertilizer, Power plants, Plastics, Pharmaceuticals, Bakeries, Fish food, Paint, Gypsum, Ready-mix concrete

- End products

- Dog kibble, Dried pasta, Treated sludge, Marble countertops, Concrete blocks, Wheat flour, Npk fertilizers, Hydrated lime, Asphalt pavement, Red clay bricks, Rubber sheets, Dust collection, Polished rice, Spice blends, Liquid shampoo, Bar soap, Steel beams, Ceramic tiles, Mortar mixes, Fly ash, Plastic pellets, Artisan bread, Gypsum wallboard, Cement powder, Granulated sugar, Acrylic paint, Reclaimed water, Cattle feed pellets, Polyurethane varnish, Quicklime, Instant noodles, Baked cookies, Precast concrete panels, Quartz sand, Roof shingles, Fish feed pellets, Aspirin tablets, Glass bottles

- Steps before

- Material Handling, Conveying, Filling Bins, Feeding

- Steps after

- Material Discharge, Level Monitoring, Bulk Solids Loading

- Input ingredients

- powdery materials, granular materials, bulk solids

- Output ingredients

- electric signals, system components activation, material level measurement

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Material level type

- Minimum/Maximum

- Installation type

- Top or side-mounted

- Operation method

- Rotary action

- Material compatibility

- Powdery and granular materials

- Contact material

- Stainless steel

- Process temperature options

- High/Low

- Certification

- ATEX-certified

- Voltage type

- Multivoltage

- Measuring paddle type

- Different types, suitable for all densities

- Working Mechanism

- Rotary action for signaling

- Installation Type

- Top or side-mounted

- Automation Level

- Manual/Automatic

- Process Temperature Options

- High/Low

- Material Level Detection

- Minimum or maximum levels

- Measuring Paddle Type

- Various types

- Density Compatibility

- Suitable for all densities

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Control panel type

- Multivoltage design

- Material construction

- Stainless steel parts

- Measurement method

- Rotary action

- Installation type

- Top or side-mounted

- Process temperature options

- High or low

- Process temperature options

- High or low

- Measuring paddle types

- Various types for different densities

- Installation type

- Top or side-mounted