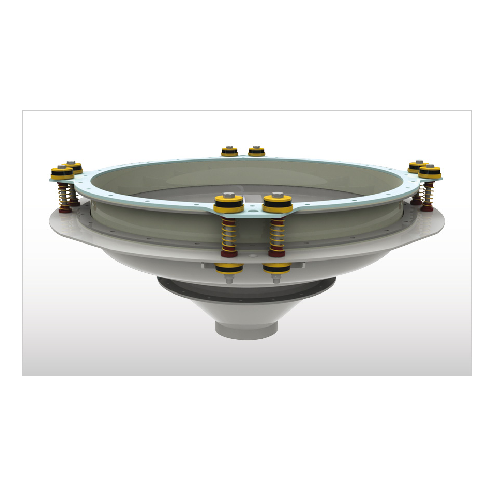

Industrial bin activator for smooth material flow

Enhance your material handling process with a solution that ensures consistent flow, preventing common issues like bridging and rat holing, while optimizing feeding efficiency. Perfect for environments dealing with powdery and granular materials where smooth discharge is essential for operational continuity.

Facilitates Material Flow and Prevents Blockages

The BAS Vibratory Bin Activator from WAMGROUP is designed for optimal material flow, addressing challenges in industries from food to heavy manufacturing. Its seamless cone design and OLI electric motovibrators generate consistent vibration, ensuring material moves smoothly, preventing blockages common in silo and hopper discharging. Particularly suited for powdery and granular products like flour, sugar, pharmaceuticals, and more, it maintains a “mass flow” condition, eliminating bridging issues. Available in carbon and stainless steel, with seals including FDA-approved options, it integrates effectively with existing systems. The BAS model offers a robust solution for upscaling production while ensuring energy efficiency and minimal maintenance, supported by WAMGROUP’s engineering expertise.

Benefits

- Ensures consistent material flow, reducing downtime from blockages and bridging.

- Operates with low power consumption, improving overall energy efficiency.

- Supports diverse applications with FDA-approved and high-temperature seal options.

- Reduces welding by 70%, increasing durability and reducing maintenance needs.

- Seamless integration into existing systems, facilitating smooth operations without extensive modifications.

- Applications

- Steel, Noodles, Biscuit processing, Cosmetics, Pesticides, Chocolate, Bakery products, Insecticides, Detergents, Granular materials, Glass, Spices, Varnishes, Rubber, Cocoa, Animal feed, Pasta, Sugar, Plastics, Soaps, Resins, Salt, Paints, Fertilizers, Pharmaceuticals, Beverages, Flour, Iron, Powdery materials, Breweries

- End products

- Dog biscuits, Spaghetti, Cream crackers, Wheat flour, Poultry feed, Cattle feed, Body wash, Bar soaps, Craft beers, Ibuprofen, Ground pepper, Rubber tires, Steel beams, Epoxy resin, Cornmeal, Glass bottles, Dark chocolate, Insect repellent, Milk chocolate, Soda drinks, Granulated sugar, Macaroni, Acrylic paint, Eye shadow, Paracetamol, Baking powder, Coffee granules, Cake mixes, Sea salt, Spray varnish, Polyethylene plastics, Nitrogen fertilizer, Lipstick

- Steps before

- Drying, Grinding

- Steps after

- Packing, Coating

- Input ingredients

- powdery materials, granular materials, flour, material inside silo

- Output ingredients

- smooth material flow, material extraction, mass flow condition, prevent bridging, avoid rat holing

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Range

- Ø 600mm ~ 2, 100mm

- Material

- Carbon steel, 304L / 316L stainless steel

- Seamless construction

- Seamless carbon or stainless steel cone

- Seal type

- SINT engineering polymer

- Electric motovibrators

- One or two OLI electric motovibrators

- Power requirement

- Low

- Welds reduction

- 70% fewer welds than traditional bin activators

- Baffle plates range

- Wide range in accordance with application

- Silo compatibility

- Suitable for shorter cone silos

- Optional features

- Suspensions for aluminum silos, fluidisation/aeration system

- Pressure version

- Negative pressure version available

- ATEX certification

- ATEX Zone 22 version available

- Food compliance

- FDA-approved, food-grade version available

- High-temperature seal

- High-temperature version available

- Material flow control

- Smooth/gyratory movement

- Automation level

- OLI electric motovibrators

- Cleaning method

- Seamless design reduces cleaning

- Batch vs. continuous operation

- Continuous

- Energy efficiency

- Low power requirement

- Abrasion resistance

- Carbon steel, 304L/316L stainless steel

- Biological compatibility

- FDA-approved, food-grade version

- Corrosive resistance

- Stainless steel (316L)

- Cleanability

- Seamless heavy-duty activator cone

- Density/particle size

- Powdery or granular materials

- FDA materials

- Food-grade version available

- ATEX certification

- Zone 22 version available

- Shape

- Half convex, half conical

- Material

- Carbon steel, 304L / 316L stainless steel

- Size Range

- Ø 600mm (23 in) ~ 2, 100mm (7 ft)

- Seal Material

- SINT engineering polymer

- Design

- Seamless heavy-duty activator cone

- Interface Type

- Flanged seal connection

- Range of Seals

- FDA-approved, food-grade version and high-temperature version

- Material Options

- Carbon steel, 304L / 316L stainless steel

- Electric Motovibrators

- One or two OLI motovibrators

- Suspensions Compatibility

- Aluminium silos

- Fluidisation/Aeration System

- Additional system available

- Outlet Spout

- With emergency slide gate

- Pressure Version

- Negative pressure version available

- ATEX Version

- Zone 22 version available