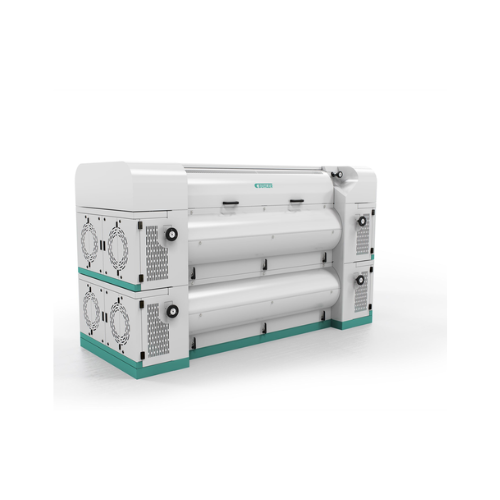

Cracking mill for oilseeds and feed

Enhance your production efficiency with a cracking mill that optimizes throughput and minimizes maintenance downtime, ensuring seamless integration into your existing processes for handling oilseeds and feed products.

Cracks and Flakes Oilseeds and Grains

The Cracking Mill OLCC from Bühler is a state-of-the-art solution for oilseed processors and feed industry businesses. This machine excels in cracking and flaking operations, essential for producing soybean meal, canola oil, and more. At the core of its design are large counter-rotating rollers, offering customizable differential speeds and roller corrugations, allowing it to handle a broad range of production demands with efficiency.

Capable of continuous and automated operations, the OLCC integrates easily into your existing production line, with a PLC-controlled system and optional smart human-machine interface for remote monitoring and automation. The innovative roller change technology drastically reduces downtime, with roller replacement taking less than two hours per pair, enhancing uptime and productivity.

Built with durable materials, the OLCC offers options for enhanced corrosion resistance, suitable for different industry requirements. Additionally, its design includes features for straightforward maintenance, such as removable doors and electronic roller gap adjustment, ensuring long-term reliability and ease of use. Fully supported by Bühler’s global service network, the OLCC promises robust performance along with engineering support tailored to your specific process needs.

Benefits

- Maximizes production efficiency with rapid roller change technology, minimizing downtime.

- Enhances product quality through customizable roller configurations, ensuring precise cracking and flaking.

- Integrates seamlessly into existing systems with smart HMI and remote monitoring capabilities, optimizing workflow.

- Reduces maintenance complexity with easy access panels and electronic adjustments, lowering operational costs.

- Accommodates a wide range of materials and production environments due to robust material options and design.

- Applications

- Cocoa, Animal feed, Baked goods, Oilseeds, Snacks, Pasta, Pet food, Confectionery, Pulses, Wheat, Grain, Beans, Spices, Chocolate, Biomass, Dairy

- End products

- Wafer biscuits, Sunflower oil, Wood pellets, Lentil flour, Wheat flour, Fish food pellets, Barley flakes, Milk powder, Soybean meal, Peanut oil, Chocolate chips, Biscotti, Cattle feed pellets, Dog treats, Breadcrumbs, Canola oil, Curry powder

- Steps before

- Pre-cleaning, Cleaning, Preparation

- Steps after

- Flaking, Pelleting, Packing, Sorting

- Input ingredients

- oilseeds, beans

- Output ingredients

- cracked oilseeds

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Roller Size

- Large counter-rotating rollers

- Customization

- Fully customizable differential speeds and roller corrugations

- Material Hardness

- Customizable hardness grades

- Automation

- Smart HMI for local and remote control

- Roller Change Time

- 2 hours per roller pair

- Maintenance Accessibility

- Removable maintenance doors, integrated sampling gates

- Electronic Roller Gap Adjustment

- Yes

- Product Bypass

- Integrated

- Magnet Strength

- Strong permanent magnets

- Pellet Production

- Oilseeds, Beans

- Automation level

- Local / Remote Control via HMI

- Roller Change Time

- Less than two hours per roller pair

- Maintenance Accessibility

- Removable Maintenance Doors

- Roller Gap Adjustment

- Electronic

- Operation Mode

- Full Automation Control

- Integration Capability

- Full Process Integration

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Footprint

- Compact design

- Roller size

- Large counter-rotating rollers

- Roller material

- Customizable hardness grades

- Control panel type

- Smart HMI interface

- Maintenance access

- Removable maintenance doors

- Sampling access

- Integrated sampling gates

- Bypass option

- Integrated product bypass

- Roller change technology

- Smart roller exchange technology

- Magnet inclusion

- Strong permanent magnets

- Control Panel Type

- Smart HMI

- Integration Possibilities

- Local and Remote Control

- Roller Configuration

- Fully Customizable Speeds and Corrugations