Single impact pneumatic hammers for flow aids

Combat material clogs and ensure smooth flow in your production line with pneumatic hammers designed to prevent bridging and rat-holing, perfect for maintaining consistent batch quality and optimizing operational efficiency.

Prevents Material Bridging and Rat-Holing

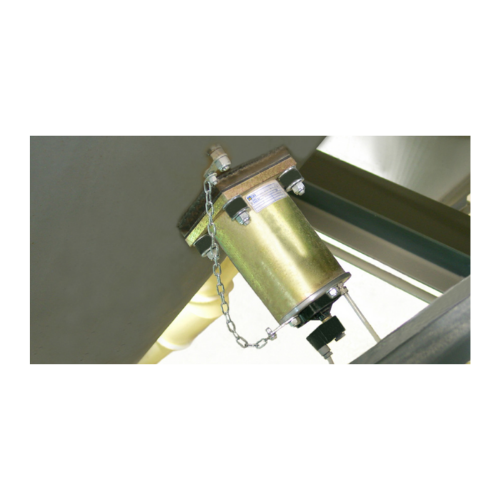

The MARTSHOCK PS Single Impact Pneumatic Hammer from WAMGROUP is engineered to tackle material flow challenges by delivering a powerful shockwave to dislodge packed or adhered powders. Designed for retrofitting without drilling, this equipment effectively prevents bridging and rat-holing in various industries including ready-mix concrete, flour milling, and plastics processing. Its robust galvanized steel and POM construction ensure durability in both indoor and outdoor settings. Operating from 3 to 6 bar, it facilitates smooth powder flow by sequentially activating hammers. The MARTSHOCK PS is available in multiple sizes and includes a mounting plate and safety chain for secure installation. Its ATEX compliance makes it suitable for potentially explosive environments.

Benefits

- Enhances material flow efficiency by preventing clogging and bridging in hoppers and silos.

- Reduces maintenance costs with easy retrofitting and installation without drilling.

- Operates safely in explosive environments, meeting ATEX certification standards.

- Durable design withstands harsh conditions, suitable for both indoor and outdoor use.

- Sequential activation minimizes energy use while maximizing material displacement.

- Applications

- Biscuits, Steel, Cosmetics, Chemical ad-mixtures, Soap, Pesticides, Drymix building materials, Coking plant products, Chocolate, Insecticides, Detergents, Distillery, Glass, Spices, Power plant (fly-ash) products, Winery, Rubber, Precast concrete, Resin, Cocoa, Animal feed, Seed processing, Sugar, Pet food, Convenience food, Varnish, Oil, Rice, Plastics, Salt, Fertilizers, Pharmaceuticals, Bakeries, Brewery, Fish food, Paint, Coffee, Flour, Iron, Ready-mix concrete

- End products

- Chardonnay wine, Poultry feed pellets, Bakery bread, Npk fertilizer, Sunflower seeds, Cream biscuits, Curry powder, Jasmine rice, Craft beer, Coke, Cocoa powder, Steel beams, Epoxy resin, High-performance concrete, Rum, Bread flour, Insect spray, Glass bottles, Automobile tires, Roasted coffee beans, Olive oil, Dry mortar mix, Dog kibbles, Granulated sugar, Acrylic paint, Fly ash cement, Milk chocolate bars, Antibacterial soap, Instant noodles, Polyethylene, Table salt, Precast concrete panels, Clear varnish, Fish feed pellets, Paracetamol tablets, Liquid foundation, Plasticizers

- Steps before

- Purification, Drying, Mixing, Grinding

- Steps after

- Packing, Loading, Silo Safety, Storage

- Input ingredients

- Output ingredients

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Pressure Range

- 3 to 6 bar (44 ~ 87 PSI)

- Shockwave Generation

- Single impact of internal piston

- Material

- Galvanized steel, POM

- Mounting Plate

- Included, welded on wall

- Sizes Available

- Three different sizes

- Operation Type

- Intermittent

- Installation Requirement

- No drilling required

- Application Environment

- Outdoor and Indoor

- Noise Reduction Kit

- Available (ATEX KIT plate)

- Timer

- Adjustable, min 30 sec

- Automation

- Fully pneumatic kit

- Working mechanism

- Impact shockwave from internal piston

- Pressure range

- 3 to 6 bar (44 ~ 87 PSI)

- Installation method

- Intermittent operation and progressive activation

- Placement flexibility

- Retrofit without drilling

- Automation level

- Manual / Progressive automation

- Environment suitability

- Indoor and outdoor use

- Size variations

- Available in three different sizes

- ATEX compliance

- Able to operate in potentially explosive environments

- Mounting components

- Includes mounting plate and safety chain

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Size

- Available in three different sizes

- Material

- Galvanized steel, POM

- Mounting Method

- Welded mounting plate

- Design

- Compact, robust design

- Application Environment

- Outdoor and indoor use

- Compact design

- Yes

- Installation method

- Welded on wall

- Available sizes

- Three different sizes