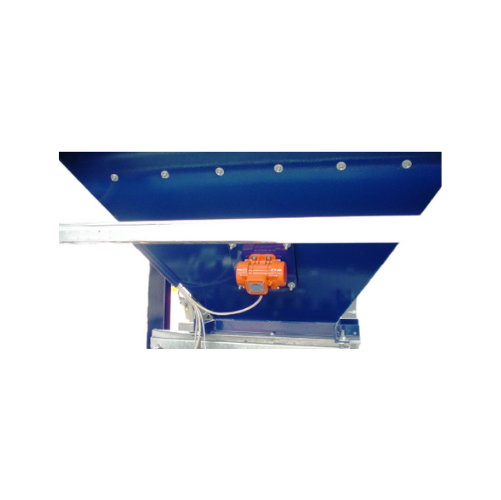

External electric motovibrators for bulk solids conveying

Enhance material flow efficiency and solve challenging discharge issues with precision-engineered motovibrators, tailored for seamless integration into vibrating equipment where controlled movement is essential.

Enhances Material Flow and Vibration Processes

The MVE External Electric Motovibrators, offered by WAMGROUP, are expertly designed to enhance vibratory flow processes across numerous industries. Encased in a robust FMEA-designed housing, these motovibrators utilize eccentric weights for precise vibrational energy management, supporting operations in conveying, screening, sizing, and compacting. Ideal for sectors such as construction, food and beverage, plastics, chemicals, and more, they efficiently aid in processing materials like concrete, flour, plastic pellets, and pharmaceuticals. With the capability to deliver centrifugal forces from 20 to 26,000 kg and operating under hazardous conditions certified by ATEX ExII3D and ETL standards, they ensure safe and effective material handling. Available in multiple motor options and pole configurations, they feature vacuum-impregnated windings and premium quality bearings for durability and reduced energy consumption. Offering a seamless integration into existing systems, the motovibrators are adaptable for linear or circular motions, ensuring flexibility in meeting specific production needs.

Benefits

- Optimizes material discharge and flow, reducing blockages and downtime in processing lines.

- Delivers variable vibration intensity for precise control, enhancing product quality and process efficiency.

- Certified for use in hazardous environments, ensuring safety in operations with flammable dusts.

- Reduces energy consumption through efficient motor operations, contributing to cost savings.

- Offers flexible integration with existing systems, accommodating diverse industrial applications.

- Applications

- Lime, Biscuits, Gas, Asphalt, Tobacco, Noodles, Biogas, Chemical ad-mixtures, Oilseed, Minerals, Bakery products, Chocolate, Cement, Waste water, Wine, Glass, Distillery, Spices, Brick, Vegetable, Biomass, Industrial solid waste, Rubber, Cocoa, Animal feed, Sugar, Marble, Varnish, Pet food, Pasta, Convenience food, Oil, Fruit, Fertilizer, Rice, Plastics, Baby food, Salt, Wood, Pharmaceuticals, Fish food, Paint, Meat, Coffee, Flour, Detergent, Gypsum, Concrete

- End products

- Dog kibble, Distilled spirits, Wood pellets, Infant formula, Precast concrete blocks, Red wine, Spaghetti pasta, Tablet pills, Hydrated lime, Fish feed, Instant meals, Rubber sheets, Animal feed pellets, Parboiled rice, Crude oil, Biogas digestate, Cement blocks, Wood varnish, Polyethylene pellets, Cocoa powder, Marble slabs, Plaster of paris, Butter biscuits, Coffee beans, Processed minerals, Recycled metals, Processed lumber, Asphalt mixes, Ground spices, Vegetable puree, Liquid detergent, Granulated sugar, Acrylic paint, Ramen noodles, Tobacco leaves, Tempered glass, Granular fertilizer, Clay bricks, Sausages, Sunflower oil, Treated waste water, All-purpose flour, Bread loaves, Natural gas, Sea salt, Canned fruits, Chocolate bars

- Steps before

- Material preparation, Particle size reduction, Initial bulk solids loading, Screening, Mixing

- Steps after

- Material discharge, Screening, Packing, Compacting

- Input ingredients

- bulk solids, building materials, plastics, chemicals, ceramics, flour, animal feed, coffee, sugar, cement, minerals, wood biomass

- Output ingredients

- conveyed materials, screened materials, compacted materials, discharged materials, flow-improved materials

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Centrifugal force

- 20 ~ 26, 000 kg

- Voltage Options

- Multiple

- Insulating Material

- Class F

- Motor Type

- Single phase, three-phase, DC

- Poles

- 2, 4, 6, 8 poles

- Windings

- Vacuum-impregnated

- Casing Design

- FMEA-designed cast casing

- Certifications

- ATEX ExII3D, ETL, Class II, Division 2

- Maximum Force

- Rotating or Linear

- Centrifugal force range

- 20 ~ 26, 000 kg

- Motor type

- Single-phase / Three-phase / DC

- Movement type

- Circular / Linear

- Force generation

- Sinusoidal centrifugal force

- Certification level

- ATEX ExII3D / ETL, Class II, Division 2

- Usage

- Hoppers / Silos / Vibrating machines

- Abrasion resistance

- High

- Cleanability

- Easy to clean surfaces

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- ATEX certification

- ExII3D

- ETL certification

- Class II, Division 2

- Casing Design

- FMEA-designed cast casing

- Motor Type

- Single phase, three-phase, or DC motor

- Poles

- 2, 4, 6, 8 poles

- Weight Range

- 20 to 26, 000 kg

- Temperature Rating for Insulation

- Class F

- Eccentric Weights

- Fitted on both shaft ends

- External Construction

- Sturdy design

- ATEX Certification

- ExII3D

- ETL Certification

- Class II, Division 2

- Centrifugal force range

- 20–26, 000 kg

- Material casing

- FMEA-designed cast

- Insulating materials

- Class F

- Customization options for small size

- PTC standard, split covers, stainless steel covers from size 60