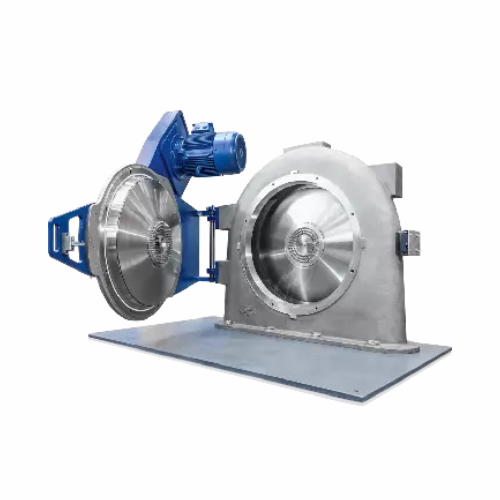

Industrial powder grinder

Achieve precise particle size reduction and classification with advanced equipment designed for continuous, high-speed operations in diverse processing environments, ensuring optimal quality for your end products.

Grinds and Classifies Powders and Granules

Hosokawa Alpine’s industrial mills and classifiers are globally recognized for their precision in grinding and classifying powders and granules. Utilizing advanced milling and classifier technology, they ensure consistent particle size for applications ranging from pharmaceuticals to food processing. With applications in mineral raw materials, chemicals, and recycling, these machines handle diverse products like quartz, acetaminophen, and whey protein powder. Operating continuously and at high speed, they are PLC-controlled for seamless integration into your production line. Designed for efficiency, they feature variable-speed motors that reduce energy consumption, and are available in stainless steel to ensure corrosion resistance. Maintenance is streamlined with an included CIP system, while customization options offer tailored solutions to meet specific production requirements. Meeting GMP and FDA standards, Hosokawa Alpine provides equipment that upholds compliance and quality in sensitive industries.

Benefits

- Ensures consistent product quality with precise particle size distribution.

- Increases efficiency with continuous, high-speed operation.

- Lowers energy costs through optimized variable-speed motor use.

- Simplifies cleaning and prevents contamination via integrated CIP system.

- Meets industry standards, ensuring compliance in pharmaceutical and food applications.

- Applications

- Detergent powders, Nuclear, Press metal powders, Plant-based proteins, Animal-based proteins, Cosmetics, Foodstuffs, Toner, Herbs, Pigments, Dairy, Chemicals, Polymers, Cosmetic powders, Kaolin, Spices, Tea, Cocoa, Animal feed, Recovered carbon black, Ceramics, Sugar, Metals, Flavours, Instant soup, Dry powder inhalants, Recycling applications, Pharmaceutics, Er tablets, Battery materials, Thickening agents, Mineral raw materials, Gypsum, Lactose, Metal salts

- End products

- Nylon granules, Laser printer toner, Wheat flour, Lithium-ion battery electrodes, Aluminum sheets, Uranium pellets, Whey protein powder, Dried basil, Xanthan gum, Cocoa powder, Reclaimed carbon black filler, Plaster of paris, Vanilla extract, Ceramic tiles, Fish meal, Ammonia powder, Recycled pvc, Protein isolate powder, Granulated sugar, Black tea leaves, Extended-release aspirin, Cyan pigment, Milk powder, Automotive metal components, Acetaminophen, Quartz powder, Copper sulfate, Bouillon cubes, Loose face powder, Lactose-free milk powder, Dpi formulations, Foundation powder, Ground cinnamon, Porcelain, Dishwashing detergent

- Steps before

- Preparation, Grinding, Granulation, Agglomeration, Mixing

- Steps after

- Classification, Packing, Testing, Coating, Final Blending

- Input ingredients

- mineral raw materials, chemicals, pharmaceuticals, cosmetics, foodstuffs, recycling materials, powders, granules, bulk materials

- Output ingredients

- ground powders, classified powders, processed granules, bulk processed materials

- Market info

- Hosokawa Micron is renowned for specializing in the manufacturing of powder and particle processing technologies, including mixing, drying, and milling equipment. They are respected for their innovative solutions and engineering excellence in industrial engineered-to-order equipment markets.

- Automation

- PLC-controlled

- Output material type

- Powders, granules, bulk materials

- Batch vs. continuous operation

- Batch / Inline Continuous

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Automation level

- Manual / PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- PLC / HMI

- Integration possibilities

- SCADA / DCS

- Discharge method

- Gravity / Pneumatic

- Compact footprint

- Yes