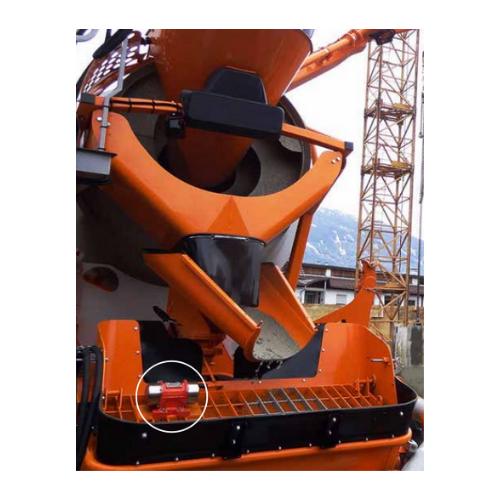

Continuous impact vibrator for aggregate reclaiming

Tackle material flow challenges head-on by preventing common issues like bridging and rat-holing, optimizing the efficiency of your bulk handling operations.

Prevents Material Bridging and Rat-Holing

The P-Series Continuous Impact Vibrators from WAMGROUP are engineered to combat material flow challenges such as bridging and rat-holing across various industries, including construction, food processing, and chemical manufacturing. These vibrators function by creating continuous shockwaves via the internal piston’s impact on the mounting base, effectively promoting material flow. With their ability to operate under temperatures up to 200°C (390°F), these vibrators are suitable for both indoor and outdoor environments, making them ideal for settings like cement plants or flour mills. The P-Series supports pressure operations from 2 to 6 bars (29 to 87 PSI), and its aluminum and powder-coated cast iron construction ensures durability and robustness. Available in three sizes, the vibrators are ATEX-compliant for safe use in potentially explosive environments. Additionally, these vibrators facilitate integration into existing production lines with features like easy installation on welded base plates and a recommended safety chain to prevent accidental dislodgment during installation or maintenance.

Benefits

- Ensures uninterrupted material flow, minimizing blockages and process downtime.

- Safely operates in explosive environments with ATEX compliance.

- Withstands high temperatures, supporting diverse industrial applications.

- Easy installation reduces setup time and maintenance efforts.

- Durable construction for long-term performance in harsh operational conditions.

- Applications

- Building, Rubber processing, Biscuit processing, Chemical ad-mixtures, Bakery plants, Paint processing, Animal feed milling, Beverage processing, Tobacco processing, Pharmaceuticals processing, Plastics processing, Dust filtration, Noodle making, Flour milling, Spices, Chocolate processing, Construction, Mining, Glass processing, Grain storage, Silo manufacturing, Coffee processing, Cement processing, Bin, Pasta, Convenience food, Detergent processing, Port technology, Power plants, Winery plants, Foundries, Industrial waste handling, Salt processing, Fertilizer processing

- End products

- Spaghetti, Biscuits, Nitrogen fertilizers, Grain storage silos, Industrial adhesives, Acrylic paints, Processed tobacco, Craft beer, Bottled wine, Ceramic tiles, Bulk cement storage, Industrial filter cartridges, Clinker, Croissants, Glass bottles, Iron ore pellets, Rubber gaskets, Instant coffee, Ground spices, Animal feed, Instant soup mixes, Liquid detergents, Ramen noodles, Pvc pellets, Industrial waste briquettes, Pain relief tablets, Steel castings, Table salt, Power plant ash bins, Wheat kernels, Flour, Chocolate bars, Concrete

- Steps before

- Material Storage, Material Conveying, Loading

- Steps after

- Aggregate Reclaiming, Material Flow Aiding, Discharge to Conveyors

- Input ingredients

- bulk materials, wet powders, electrostatic powders, clay, sludge, manure

- Output ingredients

- material flow, reduced incrustations, eliminated bridging, resolved rat-holing

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Pressure Range

- 2 to 6 bar (29 ~ 87 PSI)

- Operating Temperature

- Up to 200 °C (390 °F)

- Material

- Powder-coated grey cast iron, Aluminium

- Suitable for Explosive Environments

- ATEX-compliant

- Size Availability

- Three sizes available

- Working Mechanism

- Shockwave generation via internal piston impact

- Pressure Range

- 2 to 6 bar (29 ~ 87 PSI)

- Operating Environment

- Outdoor and indoor applications

- Temperature Range

- Up to 200 °C (390 °F)

- Installation Method

- Base mounting plate

- Welded on the wall

- Safety Features

- Safety chain to avoid accidental dropping

- Explosion Safety

- ATEX-compliant

- Material Type

- Suitable for bulk materials that stick to walls

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Operation type

- Intermittent blows for continuous operation

- ATEX certification

- Compliance for potentially explosive environments

- Material

- Aluminium, powder-coated grey cast iron

- External Body Material

- Aluminium, Powder-coated Grey Cast Iron (RAL 2009)

- Vibration Mounting Plate

- Base Mounting Plate to be Welded

- Temperature Resistance

- Up to 200°C (390°F)

- Noise Reduction Kit

- Available

- Safety Chain

- Included