External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material discharge across industries with versatile motovibrators designed to tackle challenging processing tasks, optimize production efficiency, and seamlessly integrate into your existing systems.

Enhances Material Flow and Discharge Efficiency

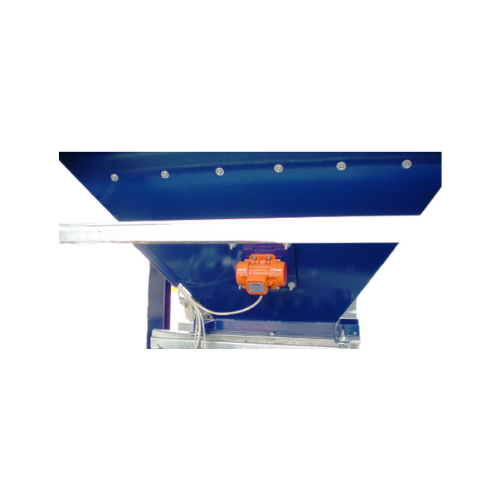

The MVE External Electric Motovibrators from WAMGROUP offer a wide range of centrifugal forces from 20 to 26,000 kg, designed to enhance material flow and discharge efficiency across various industries. These motovibrators feature a rugged FMEA-designed cast casing housing an electric motor with eccentric weights, facilitating both circular and linear vibrations depending on the application requirements. Equipped with ATEX ExII3D and ETL, Class II, Division 2 certifications, they are safe for use in environments with potentially flammable dust. Typical applications include ready-mix and precast concrete production, flour and rice milling, feed and food processing, and chemical manufacturing, producing end-products like concrete panels, animal fodder, and polymer pellets. The motovibrators are versatile, offering multiple voltage options to match global electric specifications, and they support 2, 4, 6, or 8 poles with three-phase, single-phase, or DC motors. Additionally, features like vacuum-impregnated windings and premium bearings ensure durability, while optional PTC components enhance thermal protection, making it a robust choice for diverse industrial flow-aiding needs.

Benefits

- Optimizes material discharge efficiency, reducing bottlenecks in production lines.

- Enhances operational safety with ATEX and ETL certifications for hazardous environments.

- Provides versatile integration with multiple voltage compatibility for global standards.

- Minimizes maintenance costs with durable FMEA-designed casing and premium bearings.

- Offers flexibility in vibration applications, supporting both circular and linear movements.

- Applications

- Lime, Asphalt mixing, Concrete blocks, Cosmetics, Biogas, Chemical ad-mixtures, Shot blasting, Drymix building materials, Municipal waste water treatment, Chocolate, Bakery products, Cement, Tobacco processing, Detergents, Iron and steel, Industrial solid waste handling, Distillery, Glass, Flour milling, Brick, Spices, Rice milling, Biomass, Winery, Rubber, Precast concrete, Cocoa, Ceramics, Concrete consolidation, Animal feed, Seed processing, Pet food, Convenience food, Varnish, Roof tile, Meat processing, Oil, Fish processing, Power plants, Plastics, Resins, Sand, Marble processing, Baby food, Salt, Paints, Vegetable processing, Foundries, Aluminium extrusion, Pharmaceuticals, Coffee, Wood biomass, Gypsum, Ready-mix concrete, Breweries, Fruit

- End products

- Aluminum profiles, Dog kibble, Distilled spirits, Wood pellets, Iron castings, Polished marble slabs, Sunflower seeds, Beer, Cement blocks, Rubber tires, Wood varnish, Mixed spices, Cocoa powder, Sawdust briquettes, Steel beams, Bottled wine, Epoxy resin, Electricity from coal, Ceramic tiles, Concrete pillars, Glass sheets, Milled rice, Portland cement, Croissants, Metal shot, Plasterboard, Canned vegetables, Processed fish fillets, Liquid detergent, Vegetable oil, White flour, Acrylic paint, Packaged tobacco, Chemical additives for construction, Clay bricks, Ground coffee, Pain relief tablets, Quicklime, Instant noodles, Table salt, Cured meat, Treated waste water, Baby formula, Sandpaper, Precast concrete panels, Recycled plastic, Chocolate bars, Biogas fuel, Roof shingles, Asphalt compound, Animal fodder, Polymer pellets, Drymix mortar, Lipstick

- Steps before

- Grinding, Crushing, Mixing, DryMix Building Materials Processing, Precast Concrete Production, Animal Feed Milling, Cement Processing, Fine Aggregate Mixing

- Steps after

- Screening, Vibrating, Sizing, Compacting, Concrete Consolidation, Drying, Concrete Pumps, Filling

- Input ingredients

- material flow, bulk solids, hazardous environments, potentially flammable dusts, eccentric weights

- Output ingredients

- centrifugal force, circular movement, linear movement, screened materials, conveyed materials, size compacted materials

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Centrifugal force

- 20 ~ 26, 000 kg

- Voltage

- Multiple voltages available

- Motor type

- Single phase / Three-phase / DC

- Poles

- 2, 4, 6, 8 poles

- Insulation class

- Class F

- Working Mechanism

- Single or Dual Motovibrators

- Movement Type

- Circular / Linear

- Application Method

- Attached to Hoppers/Silos

- Force Range

- 20 to 26, 000 kg

- Motor Type

- Single Phase / Three-Phase / DC

- Hazardous Environment Suitability

- ATEX ExII3D, ETL Class II

- Vacuum Impregnation

- Yes

- Bearing Quality

- Premium

- Voltage Compatibility

- Multiple Voltages Worldwide

- Automation Level

- Not Specified

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- ETL certification

- Class II, Division 2

- Motor Casing Material

- Cast Iron

- Motor Type

- Single Phase, Three Phase, DC

- Centrifugal Force Range

- 20 to 26, 000 kg

- Number of Poles

- 2, 4, 6, 8 Poles

- Eccentric Weight Position

- Both Shaft Ends

- Protection Grade

- ATEX ExII3D and ETL Certification

- Control panel type

- Standard / Advanced

- Voltage options

- Multiple voltages available

- Pole options

- 2, 4, 6, 8 poles

- Motor type

- Single phase / Three-phase / DC

- PTC feature availability

- Available from size 60

- Mass adjustment

- Split covers for quick adjustment from size 60

- Casing material

- Stainless steel on request from size 60