Vibrating extractor for silo and hopper product distribution

Ensure consistent product flow and precise distribution from your storage systems with this vibrating extractor, ideal for maintaining uniformity in processing operations.

Extracts, Meters, and Distributes Bulk Materials

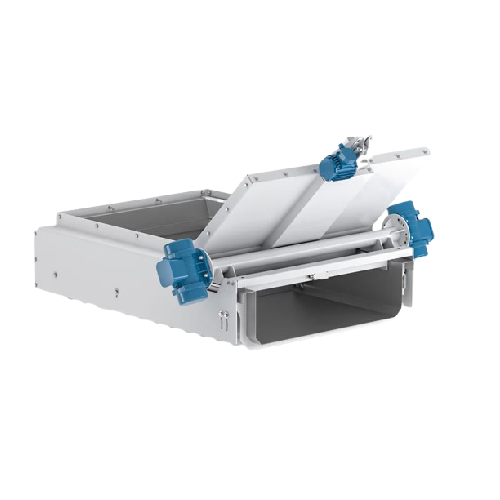

The EV Vibrating Extractor from GEA is a precise solution for extracting, metering, and distributing bulk materials directly from silos or hoppers. Specially designed for industries such as food, pharmaceuticals, and chemicals, it tackles metering challenges by ensuring consistent material flow across the outlet width. This extractor features a high-grade stainless-steel tank supported on a fixed, painted carbon steel frame with suspension elements to dampen vibrations. Its dual rotary electric vibrators allow for straightforward manual adjustment, offering flexibility in operation.

With processing applications spanning from flour and dairy powders to biofuels and chemical granules, the machine is versatile enough to handle various solid, granule, and powder types. Throughput can be customized with manual or optional motor-driven dampers, adapting to your specific production demands. The integrated sensor ensures continuous product presence, optimizing for special requirements like producing precise mixtures.

The EV Vibrating Extractor can be integrated into new or existing production lines, offering the potential for enhanced energy efficiency and precise control with optional engineering support for configurations tailored to your specific needs.

Benefits

- Ensures precise material flow and reduces waste with accurate metering and distribution.

- Minimizes operational downtime with easy manual adjustment of the vibrating unit.

- Increases production flexibility with variable throughput options via manual or motor-driven dampers.

- Enhances product purity and consistency with integrated product presence monitoring.

- Supports various industries with its robust, corrosion-resistant stainless-steel construction.

- Applications

- Food, Chemicals, Personal care, Gas and energy, Marine, Beverage, Refrigeration, Oil, Heating, Environment, Home, New food, Dairy, Pharmaceuticals

- End products

- Biofuels, Skincare creams, Refrigerants, Plant-based protein powders, Sugar, Haircare formulations, Fishmeal, Recycled materials, Dairy powder, Flour, Pharmaceutical powders, Crude oil, Chemical granules

- Steps before

- Storage, Blending, Weighing

- Steps after

- Metering, Uniform distribution, Quality control

- Input ingredients

- product from silo, material from hopper

- Output ingredients

- metered product, uniformly distributed product

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Tank Material

- Stainless Steel

- Frame Material

- Painted Carbon Steel

- Vibrating Unit

- Two Rotary Electric Vibrators

- Suspension Elements

- Varies with Extractor Size

- Automation Level

- Manual / Motor-driven Damper

- Product Monitoring

- Product Presence Sensor

- Working mechanism

- Vibrating unit with rotary electric vibrators

- Integrated steps

- Product extraction and uniform distribution

- Batch vs. continuous operation

- Continuous

- Automation level

- Manual with optional motor-drive damper

- Manual adjustment

- Eccentric weights

- Suspension system

- Variable number of suspension elements

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tank material

- Stainless steel

- Frame material

- Painted carbon steel

- Discharge method

- Vibration

- Footprint

- Variable, based on model size

- Suspension system

- Multiple suspension elements

- Vibration mechanism

- Rotary electric vibrators

- Adjustability

- Manual adjustment of eccentric weights

- Tank material

- Stainless steel

- Frame material

- Painted carbon steel