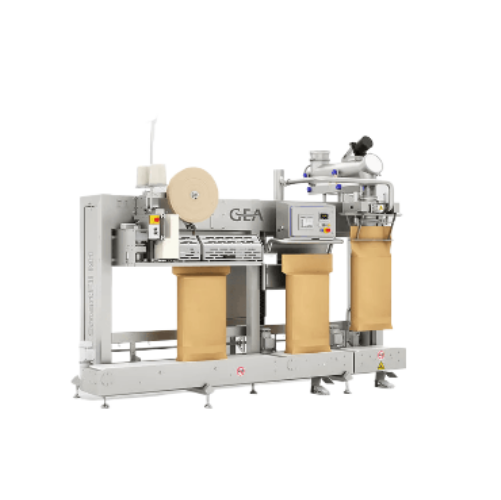

Semi-automatic powder filling system for food products

Achieve precise and flexible filling for food powders and granules with a compact, semi-automatic system, designed for easy adaptation to diverse packaging formats without compromising product integrity.

Fills, Packs, and Seals Powder and Granular Products

The GEA SmartFil M1 is a versatile powder filling and packing system designed by GEA, catering to the needs of food, beverage, and pharmaceutical manufacturers. This system stands out for its modular approach, allowing for seamless adaptation to various packaging formats, including fine powders and coarse granular products. Equipped with configurable product metering options such as vertical auger and vibratory feeder, you can efficiently fill products into open-mouth bags, boxes, or drums. With its semi-automatic operation, the SmartFil M1 is perfect for low-capacity applications, ensuring quick and safe packaging while minimizing contamination risks with its sealed filling head.

The SmartFil M1 integrates easily into production lines with its ergonomic, height-adjustable conveyor system, which facilitates rapid product and packaging changes. It offers several sealing options, including heat sealing and impulse sealing, to match your packaging requirements. Constructed from durable stainless steel, this equipment promises low maintenance and longevity. The simple operator interface allows you to swiftly adjust filling parameters and closing functions, ensuring operational efficiency. Additionally, an optional deaeration probe can improve product consolidation, making the GEA SmartFil M1 an adaptable and robust choice for diverse filling needs.

Benefits

- Enhances packaging flexibility with adjustable configurations for different product types.

- Minimizes contamination risk through a sealed filling head, ensuring product safety.

- Streamlines operations with an ergonomic design and quick-change conveyor system.

- Reduces labor requirements with semi-automatic operation and easy interface.

- Lowers maintenance costs with durable stainless steel construction.

- Applications

- Fine powders, Granular products, Coarse granular products, Food powders

- End products

- Powdered milk, Spice blends, Dried soup mix, Cocoa powder, Sugar, Infant formula, Powdered drinks, Nutritional supplements, Baking soda, Protein powder, Flour, Seasoning blends, Instant coffee

- Steps before

- Product formulation, Mixing, Sieving

- Steps after

- Sealing, Labeling, Distribution

- Input ingredients

- fine powders, coarse granular products, granular products, food powders

- Output ingredients

- filled bags, filled boxes, filled drums, sealed bags, sealed packaging

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Filling Configuration

- Semi-automatic

- Filling Volume

- Varies with bag size

- Product Metering Options

- Vertical auger / Horizontal vibratory feeder

- Filling Speed

- Low-capacity

- Sealing System

- Continuous heat sealing / Impulse sealing

- Bag Type

- Open-mouth bags / Boxes / Drums

- Automation

- Semi-automated

- Construction Material

- Stainless Steel

- Conveyor System

- Height adjustable

- Cleaning Method

- Easy maintenance (implied by low maintenance)

- Deaeration Probe

- Optional

- Filling Accuracy

- Based on metering system choice

- Sealing Method

- Glue reactivation / Sewing

- Bag Closing System

- Foldover sealer / Impulse sealer

- Operator Interface

- Configurable

- Bag Preparation

- Manual (using bag preparation station)

- Working mechanism

- Bag filling with metering auger

- Automation level

- Semi-automatic

- Batch vs. continuous operation

- Batch

- Changeover time

- Fast due to height adjustable conveyor system

- Cleaning method

- Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product granularity

- Fine powders to coarse granular products

- Product compatibility

- Powdered and granular

- Product consolidation

- Optional deaeration probe

- Machine footprint

- Compact

- Discharge method

- Footswitch operation with conveyor assist

- Control panel type

- Simple operator interface

- Feed method

- Metering auger / Vibratory feeder

- Bag clamping method

- Footswitch operation

- Sealing method

- Heat sealing / Impulse sealing / Sewing

- Metering System

- Vertical auger / Horizontal vibratory feeder

- Packaging Format

- Open-mouth bags, Boxes, Drums

- Sealing and Closing System

- Continuous heat sealing / Sewing / Impulse sealing

- Conveyor System

- Height adjustable

- Deaeration Probe

- Optional