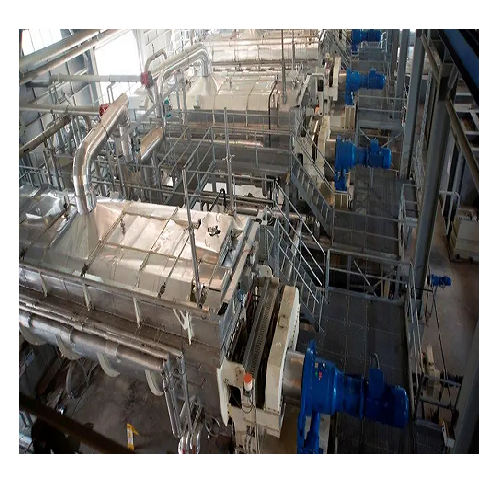

Paddle dryer for industrial sludge

Achieve consistent drying and pasteurization of complex materials with this advanced paddle dryer, designed for thorough heat transfer and hygienic treatment, ensuring your production line maintains optimal quality and efficiency.

Processes Sludge and Biomass with Efficient Heat Transfer

The ANDRITZ Gouda Paddle Dryer is engineered for maximum efficiency in drying applications, particularly suitable for sludge and biomass processing. Featuring rotating heated paddle shafts in a heated trough, this equipment ensures exceptional heat transfer and uniform product quality by maintaining consistent temperature control without back-mixing. Its specialized paddle design enables hygienic treatment and pasteurization, handling materials such as industrial and municipal sludge, polymers, gypsum, and more. Capable of drying products to specific moisture levels, it aids in producing biosolids pellets, fertilizer granules, and other end-products. Designed for continuous operation, this paddle dryer includes a vacuum option allowing for low-temperature processing, optimizing energy consumption. Constructed with corrosion-resistant materials, it stands up to high temperatures and heavy-duty use, certified by ASME, TÜV, and other international standards. With automatic integration possibilities, the unit offers a clean operation that aligns with environmental compliance and operational safety.

Benefits

- Ensures consistent product quality through precise temperature control and uniform heat distribution.

- Enhances operational safety and hygiene with fully enclosed, vacuum-capable processing.

- Offers flexible drying options to achieve desired moisture levels for various end-products.

- Optimizes energy usage with an efficient heat transfer system, minimizing operational costs.

- Provides long-term reliability and durability even in corrosive environments, backed by global certifications.

- Applications

- Chemicals, Polymers, Food, Metal powders, Cocoa, Sugar, Minerals, Milk, Industrial sludge, Drilling mud, Flour, Starch, Municipal sludge, Gypsum, Paper sludge, Digested manure, Biomass

- End products

- Processed animal feed, Metal alloy powders, Modified starch, Cocoa powder, Dried polymers, Recycled paper fibers, Granulated sugar, Dried drilling cuttings, Mineral concentrates, Bread flour, Dried milk powder, Compost, Gypsum wallboard components, Fertilizer granules, Biosolids pellets

- Steps before

- Concentration, Separation, Pre-treatment

- Steps after

- Pasteurization, Hygienic treatment, Incineration, Recycling, Packing

- Input ingredients

- sludge, industrial sludge, municipal sludge, drilling mud, paper sludge, biomass, digested manure, chemicals, polymers, gypsum, minerals, metal powders, food, milk, starch, cocoa, flour, sugar

- Output ingredients

- dried sludge, dry solids, pasteurized sludge, hygienically treated sludge

- Market info

- ANDRITZ is known for its expertise in supplying industrial ETO equipment and services, specializing in sectors like pulp and paper, hydropower, and metals. It has a strong reputation for innovation and engineering excellence.

- Heat Transfer

- Excellent due to specially shaped paddles

- Sludge Retention Time

- Long

- Average Sludge Temperature

- 100°C

- Dry Solids Level

- 35-40%

- Temperature Control

- Excellent

- Product Quality

- Uniform

- Machine Design

- Hygienic

- Operational Mode

- Fully continuous

- Plug Flow

- Good

- Temperature Range

- Low temperature possible due to vacuum

- Energy Efficiency

- High

- Construction

- Robust with accurate constant tolerances

- Lifespan

- Long, continuous lifecycle

- Heat Exchanging Surface

- High relative to volume

- Self-cleaning Capacity

- Yes, due to wedge-shaped paddles

- Shear Forces

- Yes, on paddle surface

- Flow Characteristics

- Even plug flow

- Automation

- Metris addIQ control systems

- Modification,Upgrades

- Available

- Drying method

- Once-through drying technology

- Heat transfer efficiency

- Excellent, due to specially shaped paddles

- Flow type

- Plug flow

- Operation type

- Fully continuous

- Temperature control

- Uniform product temperature

- Moisture level control

- Any residual moisture level

- Automation level

- Manual / Metris addIQ control systems

- Retention time

- Controlled for uniform end product

- Hygienic design

- Ensures pasteurization and hygienic treatment

- Energy efficiency

- High, due to compact design

- Abrasion resistance

- Yes

- Biological compatibility

- Hygienic design

- Cleanability

- Self-cleaning capacity

- Corrosive resistance (e.g. acids)

- High

- Density/particle size

- Handles various densities

- Machine footprint

- Compact

- Shape

- ω- (omega) shape trough

- Discharge method

- Adjustable overflow

- Paddle type

- Rotating heated paddle shafts

- Construction

- Robust

- Control panel type

- PLC interface

- Integration possibilities

- Metris addIQ control systems

- Discharge method

- Adjustable overflow

- Footprint

- Compact design