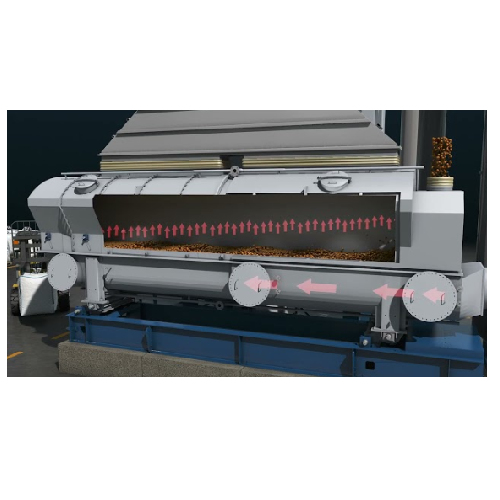

Continuous fluid bed dryers for various industrial applications

Achieve precise moisture control with fluid bed dryers, crucial for ensuring product quality across diverse materials like powders and granules. Their versatility improves outcomes in drying, cooling, and more, optimizing production in key stages.

Efficiently Dries, Cools, and Processes Powders

The Continuous Fluid Bed Dryer from TEMA Process is expertly designed for comprehensive drying and cooling of powders and granules. Utilizing fluidization principles, it offers precise control over residence time, ensuring uniform moisture removal. Ideal for minerals, chemicals, food, and biomass, it seamlessly integrates with production lines, whether in continuous or batch operations. This dryer accommodates powders like silica sand, milk powder, and fish meal with processing temperatures up to 750°C, supporting sensitive materials with gentle handling.

Engineered with a low-energy shaker mechanism, it enhances product flow and reduces friction, optimizing energy use and minimizing operational costs. Available options include static and shaking configurations, catering to different material consistencies. Crafted in durable materials, it provides robust corrosion resistance and meets industry-specific standards. Cleaning is streamlined with accessible designs and optional CIP systems. TEMA Process’ engineering support ensures customization, allowing modifications in configuration and system integration, all backed by rigorous testing for reliability.

Benefits

- Reduces energy consumption with low-frequency shaker mechanism, ensuring efficient operation.

- Provides uniform drying and cooling, enhancing product quality and consistency.

- Minimizes operational costs through integrated cooling sections and gentle material handling.

- Offers process flexibility, accommodating a wide range of materials and configurations.

- Ensures seamless integration with existing lines, supporting both continuous and batch processes.

- Applications

- Chemicals, Food, Sauces, Feed, Grains, Metal salts, Herbs, Spices, Plastics, Minerals, Biomass, Fertilizers, Fibres, Pharmaceuticals

- End products

- Dried basil, Copper sulfate, Biomass pellets, Potash fertilizer, Silica sand, Pvc granules, Vitamin supplements, Wheat flour, Npk fertilizers, Milk powder, Polyester fibers, Fish meal, Tomato sauce, Curry powder

- Steps before

- Purification, Grinding, Emulsification

- Steps after

- Sterilization, Packing, Coating, Pasteurization

- Input ingredients

- wet powder, granular materials, flakes, minerals, chemicals, food products, feed materials, biomass, sticky materials, crumbs, dextrose, rice, sugar, herbs, spices, flaked cereals, extruded cereals, milk powder, lactose, tomato pulp, citrus pulp, fish meal, fish feed, animal feed, return bread, sodium chloride, herbicides, CMC, detergents, ammonium sulphate, sodium sulphate, potassium sulphate, polymers, PVC, PVDC, plastics, EPS, fibres, metal salts, organic fertilizer, orange peel, lemon peel, sludge, manure, paper sludge, wood, biomass, refuse-derived fuel, carbon black granules, chicken manure

- Output ingredients

- dried powder, dried granules, dried flakes, dried minerals, dried chemicals, dried food products, dried feed materials, dried biomass, non-sticky materials, uniformly dried products, dried herbs and spices, dried animal feed, dried polymers, dried fertilizers, dried biomass fuels, uniform and dry product output

- Market info

- TEMA Process is renowned for its expertise in designing and manufacturing industrial drying solutions, specifically fluid bed dryers and coolers, powder processing equipment, and waste material recycling technologies, recognized for efficiency and innovative technologies across various industries.

- Air speed

- Variable 1–20 m/s

- Airflow control

- Adjustable

- Automation

- PLC-controlled

- Capacity

- Variable based on design

- Cooling option

- Integrated

- Cooling temperature

- Ambient or controlled

- Drying gas temperature

- Up to 750°C

- Drying time

- Continuous or variable

- Energy efficiency

- Low energy consumption

- Feed type

- Powder/Granular

- Process flexibility

- High

- Product temperatures

- Up to 400°C

- Shaker mechanism

- Low-frequency, high amplitude

- System design

- Continuous/Bespoke

- Volume

- Adjustable based on need

- Material compatibility

- Wide range including sticky materials

- Working Mechanism

- Fluidization via hot air

- Integrated Steps

- Drying and cooling

- Batch vs. Continuous Operation

- Continuous

- Automation Level

- PLC / Manual

- Energy Efficiency

- Low energy consumption

- Cleaning Method

- CIP / Manual

- Changeover Time

- Minimal

- CIP/SIP

- Not specified

- Handling of Sticky Products

- Yes

- Shaker Mechanism

- Low-frequency, high amplitude

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Shape

- Fluid bed

- Feed method

- Perforated bed

- Discharge method

- Shaker mechanism

- Control panel type

- PLC-controlled

- Control Panel Type

- PLC / HMI

- Integration Possibilities

- SCADA / MES

- Heat Exchanger Configuration

- Submerged / Static

- Bed Type

- Static / Shaking

- Fluid Bed Configuration

- Continuous / Batch

- Temperature Control

- Automated System

- Cooling Section

- Integrated

- Material Compatibility

- Customizable