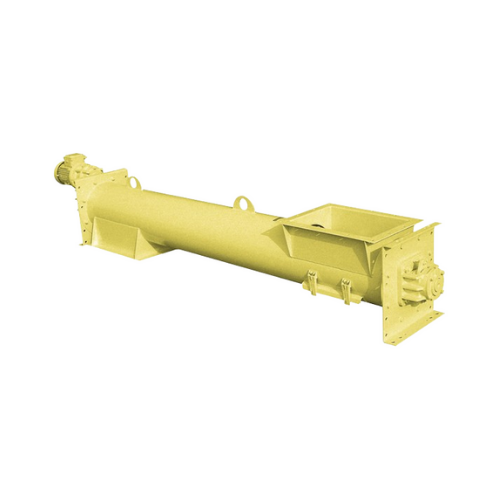

Tubular trough screw conveyors for gentle powder and granular material handling

Achieve precise powder and granular material management with minimal residue and maintain particle integrity, essential for operations in conveying and feeding processes where consistent quality and efficiency are priorities.

Conveys and Feeds Granular and Powder Materials

The CAO Tubular Trough Screw Conveyor from WAMGROUP is engineered for precision in conveying and feeding powder and granular materials across multiple industries, including flour and animal feed milling. Its modular design, available in both light and medium heavy-duty versions, features robust carbon steel construction with helicoid screw flighting. This setup ensures minimal material residue and preserves particle integrity during transport. The conveyor supports a range of applications from flour milling to animal feed additives processing and is capable of handling products such as bread flour, cornflakes, and pet food.

Equipped with a gear motor, the CAO Conveyor offers seamless integration into high-speed, continuous processes, with customizable configurations to meet specific needs. Its modular sections, available with various inlet and outlet shapes, ensure easy adaptation to existing setups. Compliance with ATEX, Zone 22 standards adds another layer of safety, making it suitable for potentially explosive environments. Maintenance is streamlined through self-lubricating intermediate bearings and adjustable shaft seals that protect against material infiltration. This conveyor is an optimal choice for operators seeking efficient, reliable material handling solutions with extensive global support for spare parts and engineering assistance.

Benefits

- Preserves material integrity with minimal residue handling.

- Facilitates seamless integration in high-speed continuous operations.

- Ensures safety in explosive environments with ATEX, Zone 22 certification.

- Provides flexibility with customizable configurations for diverse applications.

- Simplifies maintenance with self-lubricating bearings and adjustable shaft seals.

- Applications

- Animal feed, Flour milling by-products, Meals, Animal feed additives, Fish food, Pet food, Cereals, Flour, Rice milling

- End products

- Cornflakes, All-purpose flour, Bread flour, Brown rice, Fish pellets, Poultry feed, Granola, Cattle feed, White rice, Cat kibble, Dog food

- Steps before

- Grinding, Drying

- Steps after

- Packing, Mixing

- Input ingredients

- powdery materials, granular materials, flour, cereals, meals, milling by-products

- Output ingredients

- no material residue, conserved particle size, conveyed flour, conveyed cereals, conveyed meals

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Material of Construction

- Carbon Steel

- Surface Finishing

- Powder-coated

- Inlet/Outlet Spout Type

- Circular, Square, or Rectangular

- Drive Unit

- Gear Motor

- Flighting Type

- Helicoid

- Shaft Seals

- Adjustable

- Certification

- ATEX Zone 22

- Capacity

- Light and Medium Heavy-Duty Design

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- CIP / Manual

- Abrasion resistance

- Yes

- Biological compatibility

- No

- Cleanability

- Moderate

- Corrosive resistance (e.g. acids)

- Limited

- Density/particle size

- 0.5–2.5 g/cm³ / Fine to coarse granules

- ATEX certification

- Zone 22

- Conveying tube shape

- Tubular

- Material of construction

- Carbon steel

- Screw flighting type

- Helicoid

- Drive type

- Gear motor

- Section length

- Standard modular sections

- Inlet/outlet spouts

- Circular, square, or rectangular

- Shaft seal type

- Adjustable shaft seals

- Intermediate hanger bearings

- Self-lubricating available

- Flange type

- WAM standard flanges

- Discharge method

- End or side outlets

- Weight-bearing components

- Robust cast iron

- Design version

- Light-duty and medium heavy-duty

- Customization

- Available with ATEX, Zone 22 certification

- Drive configurations

- Direct gear motor, Offset gear motor

- Inlet/outlet configuration

- Circular, square, or rectangular

- Screws (augers) configurations

- Ribbon flight, paddles, others

- Shaft seals

- Gas or air-purged, grease chamber