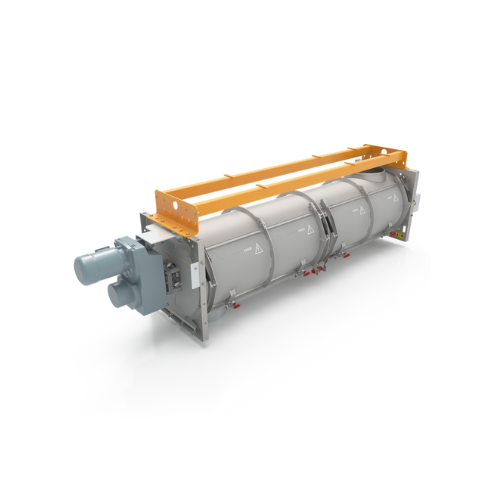

Retentioner for animal feed safety enhancement

Enhance your feed production line with a retention system designed for uniform thermal treatment, ensuring consistent product quality and improved safety by reducing contamination risks.

Ensures Uniform Retention and Thermal Treatment

Bühler’s Hytherm Retentioner revolutionizes retention and thermal treatment in pelleting processes. Utilizing a “first in, first out” protocol, it guarantees consistent treatment of powders and granules across animal feed and alternative protein lines. With retention times from 30 to 240 seconds, it supports continuous operations, boosting feed safety by minimizing contamination risks. The system features low-residue design for easy cleaning, accelerating product changeovers with minimal waste. Integrate it seamlessly with pelleting systems to achieve uniform product quality. Available in corrosion-resistant materials, it aligns with industry standards for hygiene and safety, supported by comprehensive engineering customization options.

Benefits

- Enhances feed safety by minimizing contamination risks through optimal retention times.

- Ensures consistent product quality with uniform thermal treatment processes.

- Speeds up batch changes and minimizes waste with low-residue design.

- Simplifies cleaning operations due to excellent accessibility of product contact areas.

- Seamlessly integrates with existing pelleting systems for efficient production line operations.

- Applications

- Animal feed, Baked goods, Alternative proteins, Wheat, Pulses, Pet food, Pasta, Paddy, Grain, Food ingredients, Spices, Rice, Aqua feed

- End products

- Jasmine rice, Spaghetti, Dog kibble, Chickpea flour, Wheat flour, Plant-based meat substitute, Black pepper powder, Whole grain bread, Soy protein concentrate, Parboiled rice, Fish meal, Barley grits, Cattle pellets

- Steps before

- Pelleting, Mixing, Grinding, Dough prep, Extrusion

- Steps after

- Cooling, Buffing, Packaging, Sorting, Sifting

- Input ingredients

- feed materials, raw particles, sticky formulations

- Output ingredients

- enhanced feed, uniform thermal treated products, consistent product quality

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Retention time

- 30–240 seconds

- Uniform thermal treatment

- "First in, first out" process

- Feed safety

- Minimizes risk of salmonella contamination

- Cleaning accessibility

- Excellent

- Working mechanism

- First in, first out

- Batch vs. continuous operation

- Batch

- Automation level

- Manual / PLC

- Cleaning method

- Easy cleaning

- Retention time

- 30 to 240 seconds

- Feed safety enhancement

- Minimizes salmonella risk

- Cleanability

- Easy cleaning with excellent accessibility

- Heat sensitivity

- Suitable for uniform thermal treatment

- Pellet size

- Uniform size maintained through "first in, first out" process

- Discharge method

- First in, first out

- Retention time selection

- 30 to 240 seconds

- Thermal treatment uniformity

- First in, first out

- Accessibility for cleaning

- Excellent