Pelleting Equipment

Find innovative pelleting equipment and connect directly with world-leading technology suppliers

Pelleting equipment transforms powdered, mashed, or grounded material into a denser cylindrical shape. Pellet processing compresses the fine material against a perforated die, where it will be shaped and cut. Although granulating and extrusion also produce pellet-like products, manufacturing pellets is a distinct process.

Two primary types of pellet processing equipment

The main element in the pellet machine is the die. Select the die according to the specific characteristics of your material and the manufacturing variables of your product. Preventive maintenance is another critical consideration for industrial pelleting machines. Regular upkeep prolongs the service life of the die and protects the quality of your process. Make sure to clean the die after each batch and change dies before the wear damages the machine.

There are two main categories of pellet mills or presses: the flat die and the ring die. You may also hear about screw press pellet machines, but the operating principle is closer to the extrusion process than the pelleting process.

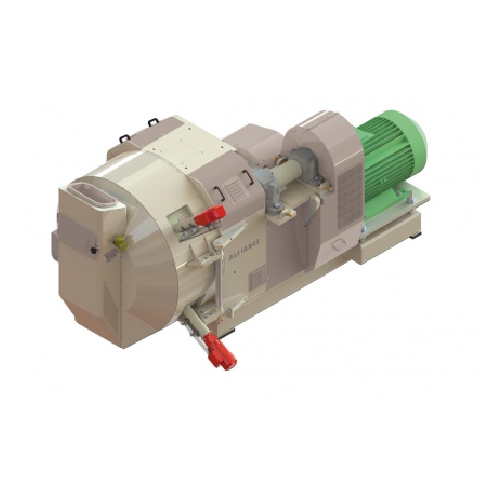

Flat die pellet machines are easier to maintain

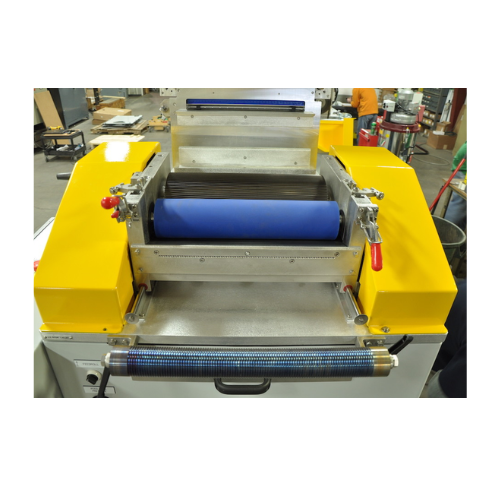

Flat die pellet machines have a perforated disk or plate, and rollers press the material through the disk holes. The vertical design of these industrial pelleting mills makes the process simpler and their cleaning more convenient.

Flat die machines fall into two groups: die-driven and roller-driven. Die-driven flat die pelletizers have stationary rollers and a rotating die, whereas, in the roller-driven type, the die is still, and the rollers rotate. The latter configuration exerts more compression power on the raw materials, so it is a better option for pelleting hard materials such as sawdust hardwoods. Meanwhile, it creates less stress on the die, prolonging its life.

Flat die presses are typically used to make biomass pellets from wood, manure, straw, alfalfa, or fodder. However, this technology is also suitable for small-scale animal feed production.

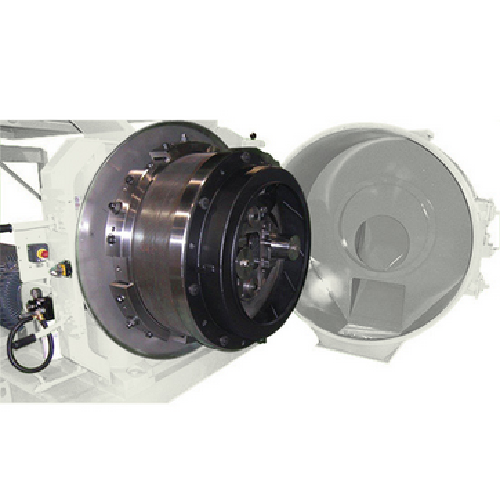

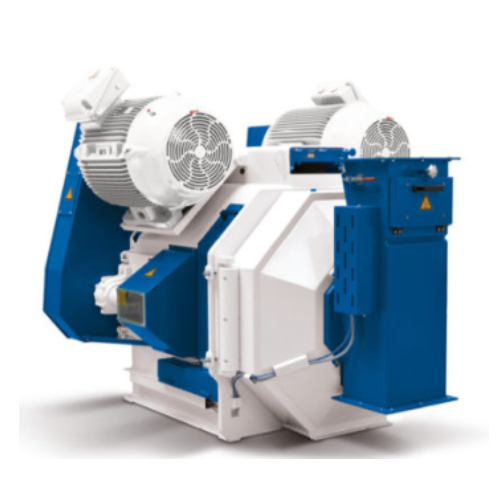

Ring die pellet manufacturing equipment is suitable for mash materials

As the name suggests, the die in a ring pellet processing mill is perforated onto a circular plate. This pellet machine can be horizontal or vertical, depending on its feed orientation.

The ring die in a horizontal pellet press is, ironically, placed vertically. The mill receives moisturized mashed and mixed ingredients into its interior chamber, where rollers compress them against the rotating die. The friction between the rollers and the die heats the material as it passes through the holes of the die. The blades cut the material into hot dense pellets at the set size. Horizontal ring die pelletizers are commonly used in the animal feed industry.

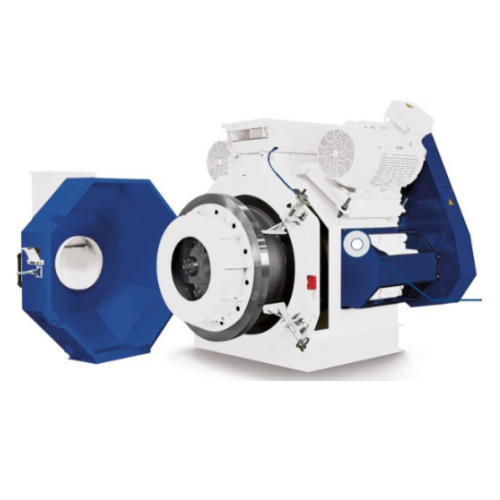

Vertical ring die systems generate centrifugal force

The ring die is placed horizontally in vertical pellet machines. But the name of vertical pellet is given because the hopper is above the ring die, letting the raw materials fall directly into the ring die. The plate and the rollers rotate in opposite directions and at different speeds, creating a centrifugal force. Such pellet mill equipment is frequently used for pellet manufacturing in the biomass industry.

Pelleting equipment often find applications in the feed and biomass industries. It is generally possible to produce feed pellets using a mill designed for biomass materials, but the opposite cannot be done. The technical reason is that biomass materials are not as soft and malleable as feed ingredients and thus require a more resistant die.

Pellet processing for feed

An industrial feed pelleting line involves a hammer mill, mixer, pre-conditioner, pellet mill, and cooler. Pellet presses are used to produce compound feed and feed concentrates, as well as specialized feed for poultry, swine, cattle, and other farm animals. Sinking pellets may also be made using a pelleting machine, but aquafeed products are typically produced with an extrusion line.

For farm production or small-scale production, there is a more basic pellet manufacturing process involving a flat die pellet. It is a vertical process, where the mixed ingredients are fed through a hopper on the top and descend into a turning roller that presses them against the die.

Mind the gap between the roller and die

Pellet processing appears simple, but the range of variables makes it complex. The operator handling pelleting equipment must set the distance between the die and the rollers, the length of the cut by the blades, control the steam in the pre-conditioner, and establish the rotating speed, heat, and flow rate. They also need to keep an eye on the electrical motor settings and the overall performance.

Automatic pellet mills self-adjust the gap distance between the roller and the die. But in manual pellet machines, you need to adjust the distance. If the roller is too close to the die, this will reduce the life of the die. On the other hand, if the distance is too great, it causes efficiency loss.

Raw materials determine process setting in biomass pellets

Pellet manufacturing lines for biomass or biofuel pellets comprise a cutter or chopper (in the case of wood), a hammer mill, a pellet mill, and a cooler. Fine particles from powdered biomass or sawdust are pressed into the holes of the die to produce solid and compact pellets.

Biomass is easier to handle than feed during the pellet production process. However, biomass pellets present more challenges because the mill settings change according to the raw material. At the same time, biomaterials turned into pellet fuel and fertilizer pellets are safer for the environment than unprocessed biomass.

What are you making?

Alfalfa meal

Aquafeed

Bioplastics

Carbon black

Chicken feed

Cottonseed meal

Extruded aquafeed

Feed concentrates

Fishmeal powder

Floating pellets

Homeopathy

Kaolin

Limestone

Nitrogen fertilizer

Pellet fuel

Pelleted feed

Plant waste

Polymers

Rodenticides

Shrimp feed

Sinking pellets

Slow sinking pellets

Sludge

Straw

Synthetic resin

Vegetable seeds

Wood pellets

Which pelleting technology do you need?

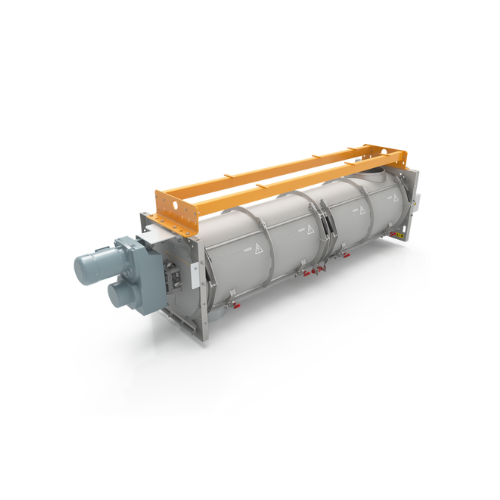

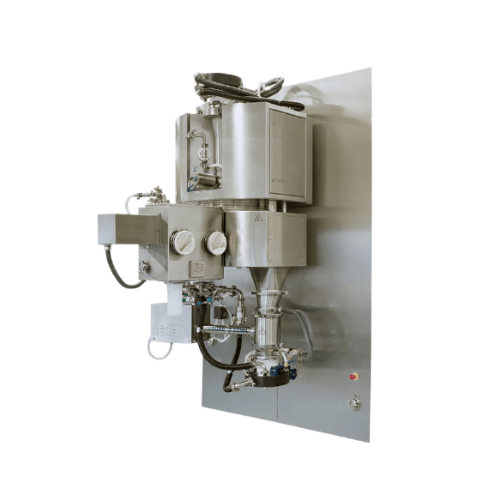

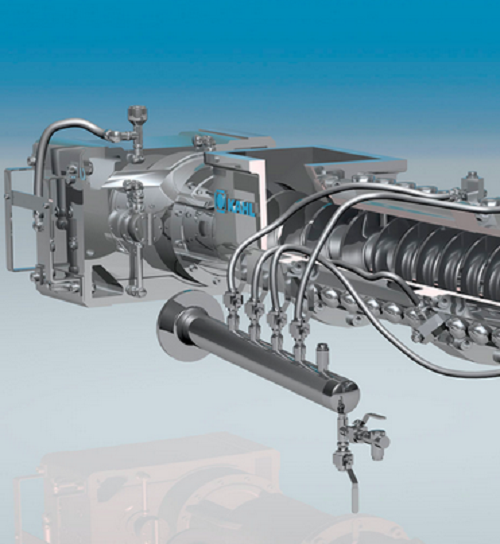

Retention time barrel for feed pelleting

Enhance your feed processing efficiency with a specialized retention time barrel, ...

Pelleting and spheronizing equipment for chemical granulates

Optimize your production line with versatile pelleting and ...

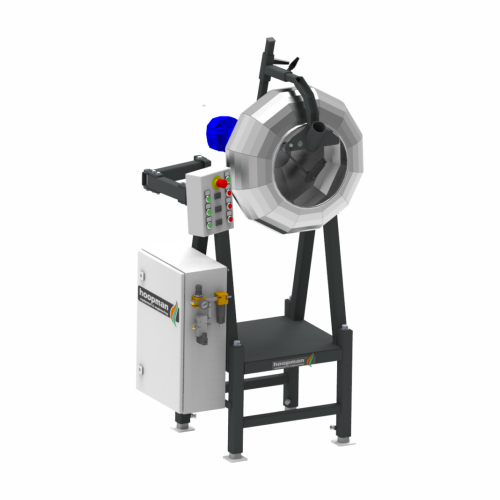

Pelleting equipment for precision seed treatment

Achieve consistent and precise coating of seeds with exceptional control ...

Pellet mill for noise-reduced pelleting

Optimize production with a pellet mill designed to minimize noise and enhance lubri...

Rotary Seed Pelleting Machine

When pelleting large batches of seeds like flower, vegetable, or agricultural types, it is imp...

Seed Pelleting Machine

Seed pelleting or encrusting is the addition of materials like powders and liquids to seeds to increas...

Pelleting line for manure fertilizer

Manure fertilizer needs to be made marketable by making them visually attractive, with...

Pelleting press for feed and petfood

The production of agricultural feed and pet food products requires machines and plants...

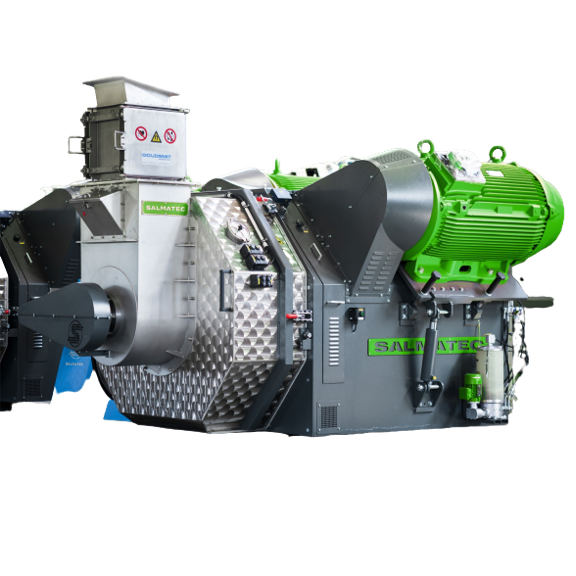

Pelleting press for biomass

Utilization of biomass for energy and other applications requires consistent and reliable compac...

Pelleting press with overhead drive

Production of certain pelletized products requires working with output products of a pa...

Hygienic pelleting press

The production of pelletized or granularized food products requires hygienic presses designed for hi...

Small scale pelleting press

Many industries require reliable pelletizing equipment with smaller scale production capacities....

Feed mill compactor for improved pellet quality

Optimize your feed production with a compactor designed to enhance pellet ...

Table roller mills for mineral raw material comminution

Achieve precise mineral raw material comminution and energy-effic...

Pellet mills for feed, plastics, and industrial products

Optimize pelleting output across diverse materials with precisio...

High-capacity pelletizer for oilseed meal processing

Maximize throughput and ensure consistency in your pelleting process...

Retentioner for animal feed safety enhancement

Enhance your feed production line with a retention system designed for unif...

Pellet mill for powdery animal feed products

Maximize plant efficiency and product quality with a versatile pelleting solu...

Industrial pellet mill

At the industrial level, the application areas of pellets range widely in fields such as feeds, biomas...

Pellet mill for high efficiency animal feed production

Achieve stable, vibration-free pellet production with enhanced ene...

Pellet mill for animal feed production

Optimize your feed production with a robust pellet mill designed to enhance the dura...

Product intake solutions for feed processing

Optimize your feed production with efficient material intake systems, ensurin...

Counterflow pellet coolers

Optimize temperature control and enhance product integrity in your feed production line with prec...

Process automation for feed mills

Optimize your feed production line by seamlessly integrating advanced process automation ...

Compactors and granulators for powdery products

Transform loose powders into dense, free-flowing granules that enhance han...

Gear pelletizer for stable cylindrical pellets

Achieve uniform pellet size and stability in your production line with a lo...

Ultra-fine grinding jet mill for coarse and fibrous materials

Effortlessly achieve ultra-fine particle sizes in coarse a...

Compact granulator for plastic comminution

Optimize your plastic recycling operations with a compact granulator designed t...

Grass and alfalfa encrusting line

Enhance seed performance with precise encrusting technology, ideal for agricultural seeds...

Organic seed coating lines

Achieve optimal seed coating with a natural, biodegradable solution that minimizes energy use and...

Integrated coater and dryer for fragile seeds

When you need to gently coat fragile seeds like cucumber, melon, and beans, ...

Mid-capacity film coating solution

Enhance your seed coating and biofuel pellet production with a customizable turn-key sol...

Rotary seed coating system

Enhance seed coating precision with high-capacity rotary systems, minimizing damage and boosting ...

Liquid matrix priming unit

Ensure seed vitality and improve germination rates with advanced liquid matrix priming, designed ...

Pelletizer for pharmaceutical and biotech applications

Achieve precise pellet formation with adjustable pan angles and li...

Air pelletizer for wood and natural fiber compounds

Optimize your pelletizing process with air-based cooling and conveyin...

Underwater pelletizing system for thermoplastic materials

Optimize your thermoplastic pellet production with a reliable ...

Compact laboratory mixer for high-shear granulation

Streamline your R&D processes with advanced mixing and granulati...

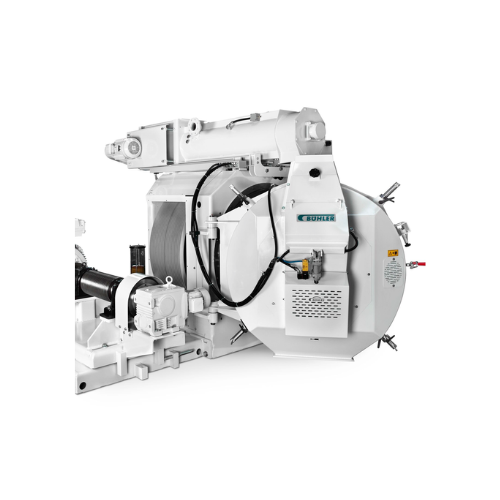

High-capacity ring-die pellet mill for animal feed production

Optimize your high-capacity feed production with this pell...

Laboratory pellet press for testing and formulation

Achieve precise pellet formulation and performance testing with versa...

High-capacity pellet crumbler

Achieve precise pellet size reduction with this high-capacity solution, designed for effortles...

Small-scale pellet mill for animal feed production

Achieve precise pellet formulation for diverse feedstocks with an effi...

Underwater pelletizer for sticky thermoplastics

Enhance pelletizing efficiency for challenging products with optimal therm...

Centric pelletizer for direct extrusion

Effortlessly transform materials into uniform granules with our high-speed pelletiz...

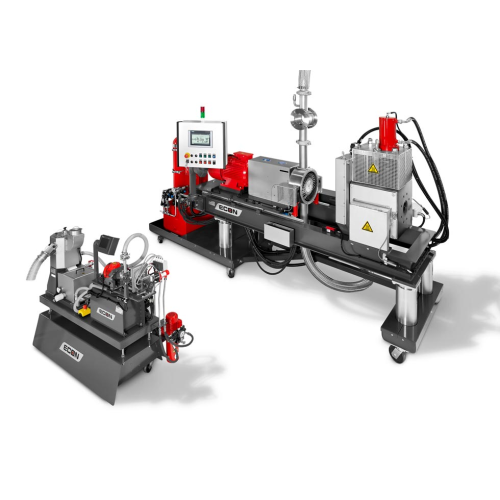

Twin screw pelletizer for continuous production 150 kg/h

Achieve precise pellet density adjustments and seamless integrat...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Pellet mill for biomass and sunflower hulls

Achieve high-speed, continuous production of durable pellets from varied mater...

Ball mill for chocolate, cocoa, and nut products

Optimize your grinding processes and achieve perfect product consistency ...

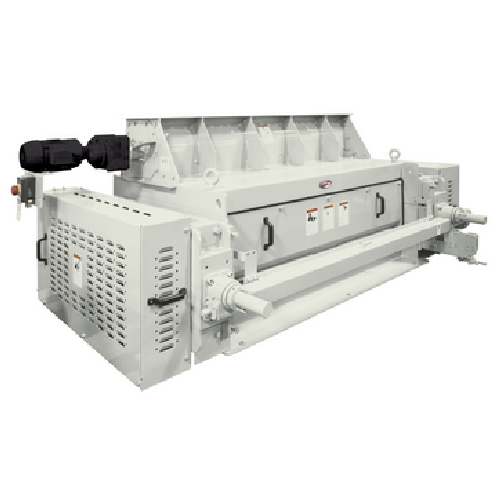

High-throughput hammer mill for animal feed production

Ideal for high-throughput operations, this hammer mill ensures pre...

High-speed mixer for dough production

Achieve consistent dough quality and streamline your production process with this ver...

Pelletizer for consistent plastic pellet production

Achieve precise pellet sizes consistently with this flexible solution...

Automatic strand pelletizer for reinforced and filled polymers

Optimize your polymer production with precise pelletizing...

Micro pelletizer for thermoplastics

Achieve precision in micro pelletizing with a solution engineered to reduce turbulence,...

Pultrusion pelletizer for long glass fiber thermoplastics

Engineered to tackle the challenges of cutting and pelletizing...

Strand pelletizer for small production lines

Achieve consistent and precise pellet sizes with our strand pelletizer, ideal...

Industrial water bath for pelletizing processes

Enhance pellet quality and efficiency with a customizable water bath desig...

Advanced vacuum air dryer for pelletizing strands

Efficiently remove residual water from polymer strands with a vacuum ai...

Wet granulating equipment for pharmaceutical industry

Enhance production efficiency and safety in high-potency pharmaceut...

24-ton laboratory pellet press

Achieve precise pellet formation with reliable 24-ton pressing power, ideal for compaction of...

Pharmaceutical r&d granulation system

Optimize your pharmaceutical research with a versatile small-scale granulation system...

Pharmaceutical bottom-drive high shear granulator

Achieve optimal granule uniformity and precise control over moisture le...

Single pot processor for granulation and drying

Streamline your pharmaceutical production with an integrated solution that...

Fluid bed processing of pharmaceuticals

Enhance your pharmaceutical production with versatile fluid bed processors, enablin...

Wheat processing systems for industrial applications

Maximize efficiency in wheat processing with a system designed for p...

Counter flow cooler for feed pellet cooling

Optimize the cooling process of your feed pellets with precision, ensuring uni...

Horizontal bale feeder for high viscosity rubbers

Efficiently process full rubber bales into granules or compound materia...

Pellet mill for powdery product processing

Transform powdery materials into durable pellets with precision and efficiency,...

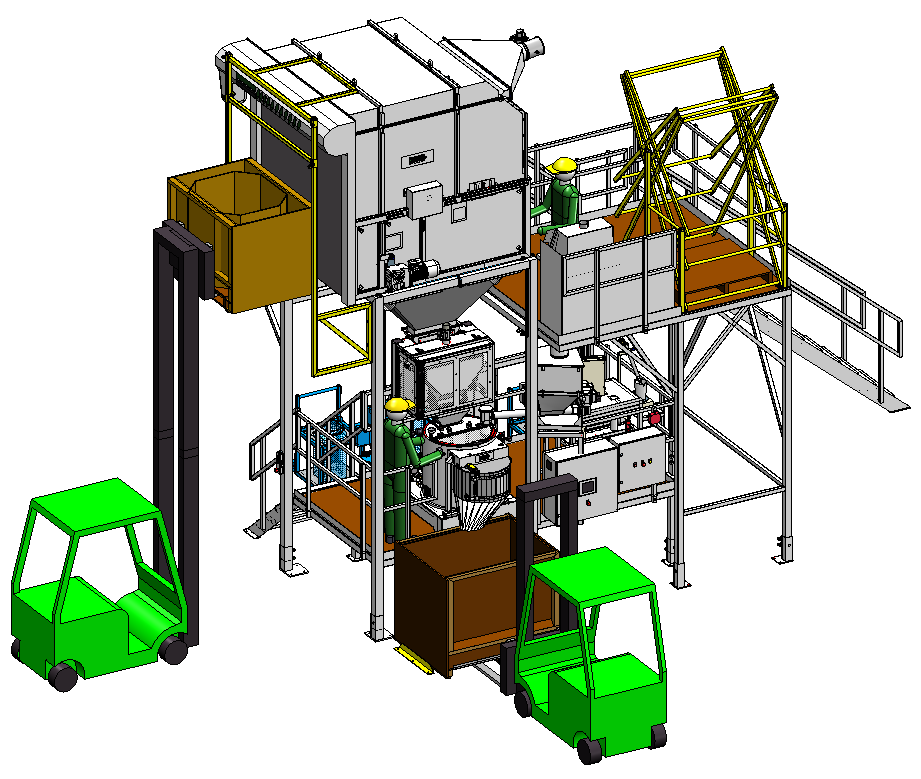

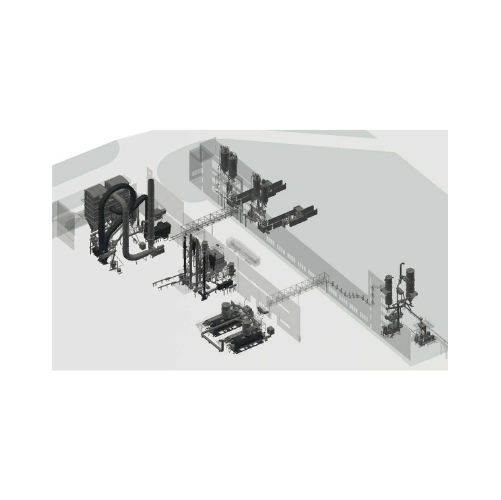

Complete pellet line

Large industries are shifting towards more environment-friendly technology, such as recycling wastes and...

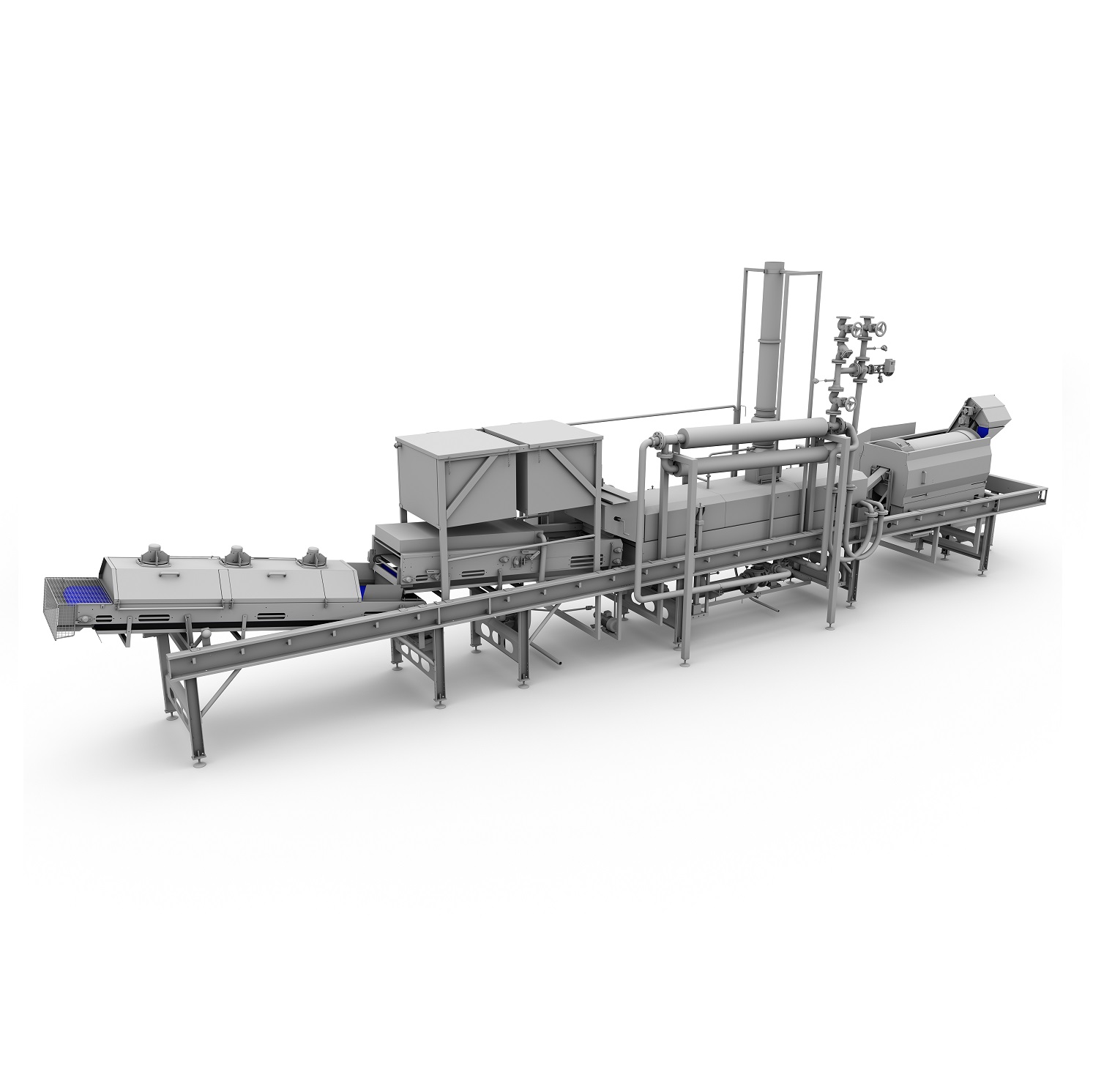

Pellet snacks frying line

Pellet-style snacks represent a broad food sector category. They are consumed worldwide and vary a...

Particle analysation monitor

Products like granules, tablets and capsules require inspection at numerous steps in the produc...

Organic soybean feed extruder

Soybeans are an essential ingredient in the creation of protein-rich animal feed. To achieve h...

Micro powder dosing system

Micro dosing of powders and small components can be a major obstruction in the production process...

High capacity grading sieve

An industrial vibratory separator machine is multi-purpose, able to carry out a variety of diffe...

Evaporator for manure fertilizer

Traditionally, liquid manure processing can lose some important nutrients. An efficient ful...

Continuous pellet cooler

Cooling is a very important and critical process for feed hygiene and pellet durability index. Pelle...

Counterflow pellet cooler

Food and feed industries require the highest standards of hygiene and sanitation. This entails fre...

Pellet hardness tester

Control the quality of your pelletizing processes using a pellet hardness tester. Pellet hardness is o...

Silo sweep auger

When you store products with good gravity flow (wheat, maize, barley, grains, granules, etc.) in flat bottom ...

Pre-conditioner for breakfast cereals

Extruded breakfast cereal products are a popular and lucrative product class. In case...

Big bag solutions

Management of big bags requires specialist handling and selection of cost-effective configurations for fill...

Tumble dryer for granulated plastics

Vacuum drying at high temperatures is important in the production of granulated plasti...

Deduster for plastic granules

Industries that use plastic granules see better product quality and decreased equipment wear a...

Laboratory granule dedusting analyzer

High quality clean bulk materials are used in many industries including plastics, foo...

Small scale deduster for plastic granules

Industries that use bulk plastics see better product quality and decreased equip...

Deduster for injection moulding

High quality injection molded plastic parts require clean bulk resins free of dust and strea...

Annular gap expander for compound feed

Compound feed processing often requires a means of kneading and mixing input substra...

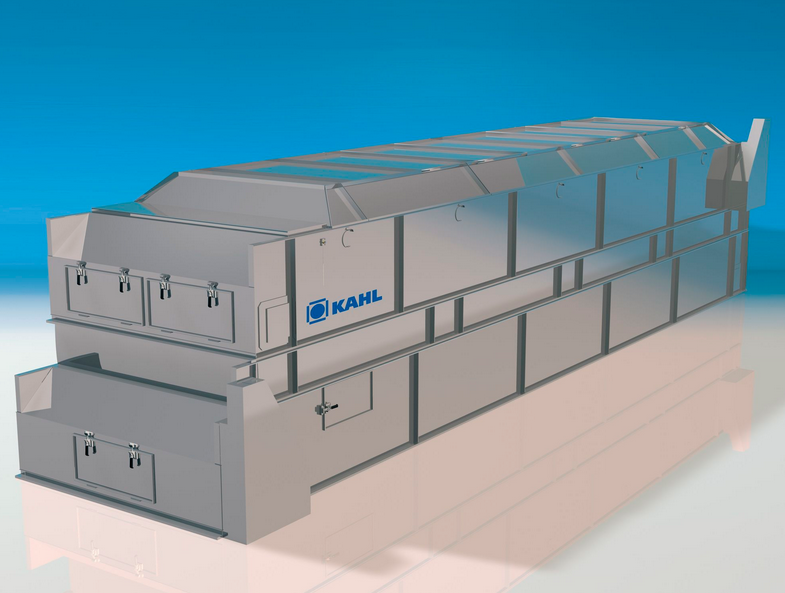

Belt dryer for wood

Processing of wood and biomass into pellets or other volume reduced products requires careful and consist...

Belt dryer/cooler for pellets and granules

Many industries that process materials in pellet, powder, or crumble form need ...