Underwater pelletizer for sticky thermoplastics

Enhance pelletizing efficiency for challenging products with optimal thermal management, ensuring consistent granule quality even for sticky compounds and high throughput rates.

Pelletizes Thermoplastics and Recycled Polymers Efficiently

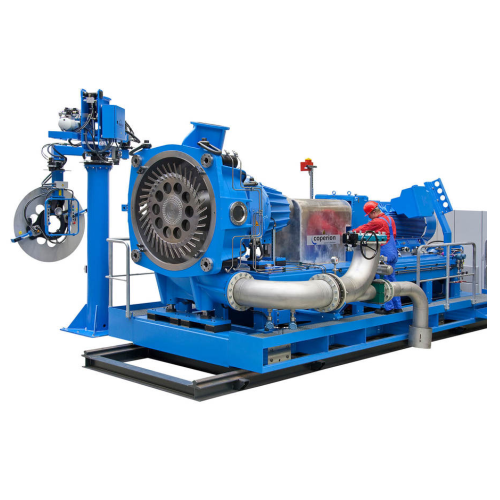

The Underwater Pelletizer UG from Coperion is designed for high-efficiency pelletizing of thermoplastics, polyolefins, and sticky compounds. This specialized equipment leverages a semi-automatic process and optimized flow channels to manage high throughput rates, making it ideal for continuous operations in plastics and chemical productions. With a maximum throughput capacity of up to 125 t/h for polyethylene and 100 t/h for polypropylene, it ensures consistent pellet quality.

The UG’s design includes an innovative heating channel system, preventing freezing during start-up and fostering efficient heat distribution across the die plate. Its construction from wear-proof material alloys extends the life of the die plate and pelletizer knife, reducing maintenance frequencies and costs. Additionally, its energy-efficient design minimizes pressure build-up and offers gentle handling of sticky materials.

This pelletizer integrates seamlessly into existing production lines, offering remote monitoring and requiring fewer personnel for operation. It accommodates diverse production needs with configurations for different knife speeds and die plate sizes, ensuring adaptability and robust performance in various industrial environments.

Benefits

- Enhances production efficiency by maintaining high throughput rates with minimal operator intervention.

- Minimizes energy costs through optimized flow channel design and variable-speed motor control.

- Offers extended lifespan of components, reducing long-term maintenance costs and downtime.

- Prevents material freezing with its innovative heating system, ensuring uninterrupted production.

- Easily integrates into diverse production lines, supporting flexible manufacturing operations.

- Applications

- Chemicals, Polyolefins, Plastic recycling, Thermoplastics, Sticky products

- End products

- Sticky masterbatch compounds, Recycled polyolefin pellets, Polyethylene (pe) granules, Pvc granules, Polypropylene (pp) pellets, Thermoplastic elastomer pellets

- Steps before

- Polyolefin production, Plastic processing, Compounding

- Steps after

- Cooling, Drying, Conveying, Packing

- Input ingredients

- polyolefins, thermoplastics, PP, PE, sticky products

- Output ingredients

- pellets, processed polyolefins, processed thermoplastics

- Market info

- Coperion is known for its expertise in manufacturing industrial compounding and extrusion equipment, bulk materials handling systems, and services for various industries, such as plastics, chemicals, and food processing, with a strong reputation for innovative engineering solutions and customer support.

- Max. permissible pressure of the heating medium

- 50-65 bar

- Max. knife speed

- 1, 218-800 min-1

- Drive power / min. installed motor power

- 20-320 kW

- Max. throughput rate PE

- 7-125 t/h

- Max. throughput rate PP

- 12-100 t/h

- Die plate bore size

- Customizable

- Heating channel system

- Optimized

- Wear-proof material alloys

- Specially developed

- Automation level

- Semi-automatic

- Energy efficiency

- Energy saving

- Batch vs. continuous operation

- Continuous

- Start-up process

- Simple start-up

- Personnel requirement

- Fewer personnel required

- Thermoplastics Compatibility

- Yes

- Polyolefin Compatibility

- Yes

- Sticky Products Handling

- Yes

- Thermal Resistance

- Yes

- Machine Footprint

- Depends on model size UG 300 to UG 1, 250

- Die Plate Size

- Varies with number of bores for high throughput

- Control Panel Type

- Semi-automatic

- Discharge Method

- Underwater pelletizing

- Heating Channel System

- Optimized for even and intensive heating

- Knife Rotor

- Splash guard and knife rotor easy mounting and dismounting

- Control panel type

- PLC-controlled

- Integration possibilities

- SCADA / PLC Integration

- Start-up process

- Semi-automatic

- Product handling

- Energy saving and gentle