Feed Pelleting Equipment

Find pelleting equipment for feed products and connect directly with a global network of leading technology providers.

In the feed industry, pellets are a convenient way of feeding livestock with a balanced nutritional meal that depends on the animals and their stage of production. A wide range of formulations that combine multiple ingredients can be done with feed pelleting equipment. But the industrial pelleting line involves more than a pellet mill, it also contains a hammer mill, a mixer, and a pre-conditioner that prepares the formulated material to be pelletized. Once the feed pellets are formed and cut to size, they go into a cooler to reduce the excess moisture, and the temperature to increase their hardness and shelf life.

The pelleting process amalgamates ingredients for higher-quality feed

Industrial feed pelleting lines are used to produce a wide range of feed products. Feed formulations for farm animals such as poultry, swine, and cattle are pelleted into compound feed and feed concentrates to facilitate handling and rationing preserving their balanced and nutritional content.

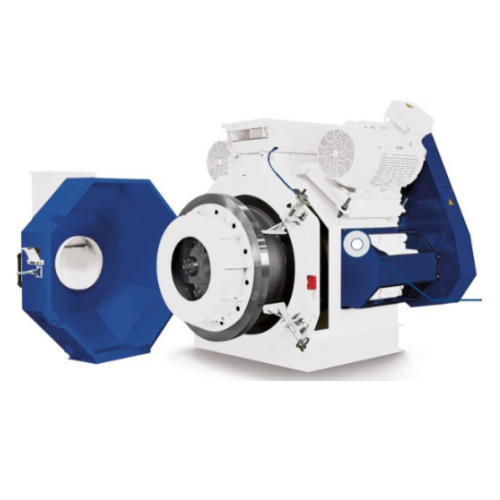

The use of pellet equipment needs to combine steam for better compacting of the previously ground and mixed ingredients, to deliver a denser feed with more palatability and digestibility properties, hence a higher-quality feed. In the industry, you will find flat die or ring die pellet mills, the first one more suitable for pelletizing single feed ingredients or small-scale production, and the second one widely used in feed mills facilities worldwide.

Flat die pelleting equipment for small-scale feed production and ring die for industrial production

There are two primary types of pelleting equipment: flat die pellet machines and ring die pellet machines. Both methods are used for feed processing, mainly depending on the moisture content of the input material and the aimed production capacity.

Flat die pellets are more suitable for pelletizing single-ingredient feed such as alfalfa or fodder or a balanced feed in small-scale production as on a farm. On the contrary, ring die pellets are great to make compound feed, concentrated feed, and many other formulations that include different types of feed ingredients and large production.

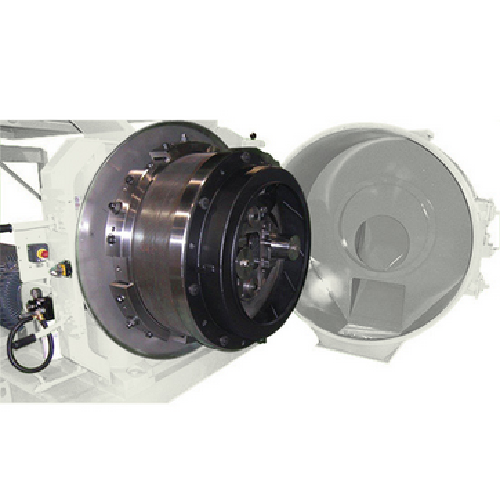

Wet ingredients are typically made with ring die pellet equipment. The material is compressed by rollers onto a rotating die, that is forced through the openings. Dry materials, especially ingredients with a harder granular structure, are pelleted with a flat die system, which can apply greater compression power. But the pellet mill itself cannot do the entire job, it needs complementary equipment to achieve the results.

Complementary equipment to a pellet mill machine

To obtain good results from a pellet mill, it is necessary a good grinding and mixing of the ingredients, but at the same time, some complementary equipment will help to achieve the desired results. It is important to have a system to add liquids and vapor, with the right piping size, valves, and traps. It is also crucial to have a feeder that supplies the ground and mixed ingredients uniformly into the pellet mill, a common feeder is a screw conveyor with variable speed. The screw conveyor will get the meal into a conditioner.

A conditioner enhances the quality of the pelleting process and the pelleted product. Conditioning means mixing the dry ingredients with steam, water, and/or molasses, making the material flexible for pelletizing, hence, increasing quality and productivity.

Cooling down the pellets to enhance their hardness and shelf life

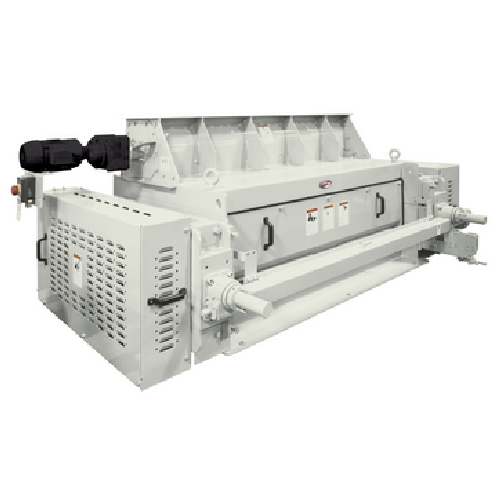

Right after the pellets are evacuated from the pellet mill, they need to be cool down to reduce their temperature and remove their moisture content. This will enhance their hardness and shelf life. In the feed mill industry, there are basically three types of coolers: counterflow, vertical and horizontal.

Counterflow coolers are commonly seen in pellet lines because they are easy to operate, need little space, and are low maintenance. Its name counterflow comes from the fact that the pellets enter from the top and the air enters from the bottom, in the counter direction of the pellets’ flow.

Vertical coolers also receive pellets from the top, need little space, and are low maintenance. But they have a tendency to be blocked due to the compaction of high-moistured pellets and work better with pellets of small diameter. On the other hand, horizontal coolers need frequent maintenance, more space, and they are not as easy to operate as the other two.

A good upkeep of the pelleting equipment lowers maintenance costs

Breaking down the costs of a feed mill or pelleting line, the pelleting process is the most expensive operation, because it has a big front investment, needs frequent maintenance and costly reparations, and consumes a large amount of energy.

Pelleting equipment needs good upkeep while in operation, cleaning the surroundings of the machine frequently or at least after every batch and reusing if possible the spilled feed, cleaning the surfaces in the feeder, the conditioner, and the pellet that are in contact with meal or moisture, cleaning any dust or liquids that may be spilled. Cleaning the die and checking its state as well as adjusting the rollers are also activities that should be done on a frequent basis. This upkeep plus preventive maintenance will reduce reparation costs and prolong the life of the machine.

Which feed pelleting technology do you need?

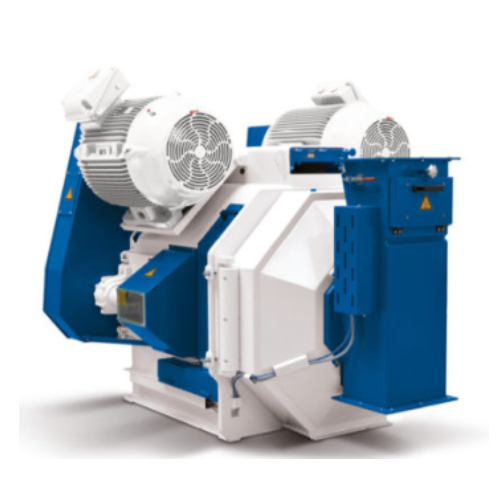

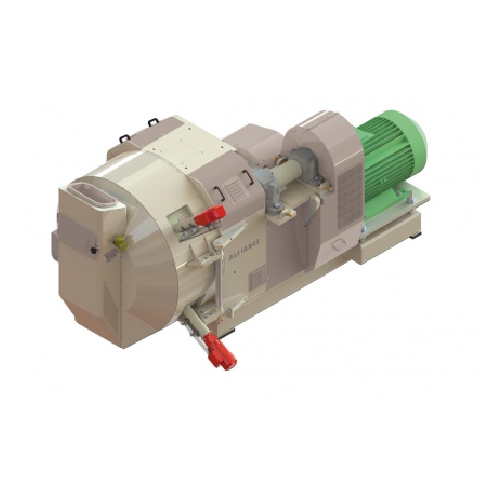

Pellet mill for high efficiency animal feed production

Achieve stable, vibration-free pellet production with enhanced ene...

Pellet mill for animal feed production

Optimize your feed production with a robust pellet mill designed to enhance the dura...

Counterflow pellet coolers

Optimize temperature control and enhance product integrity in your feed production line with prec...

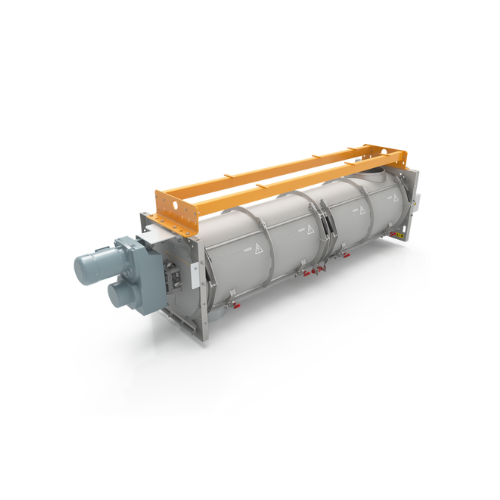

Retention time barrel for feed pelleting

Enhance your feed processing efficiency with a specialized retention time barrel, ...

Feed mill compactor for improved pellet quality

Optimize your feed production with a compactor designed to enhance pellet ...

Gear pelletizer for stable cylindrical pellets

Achieve uniform pellet size and stability in your production line with a lo...

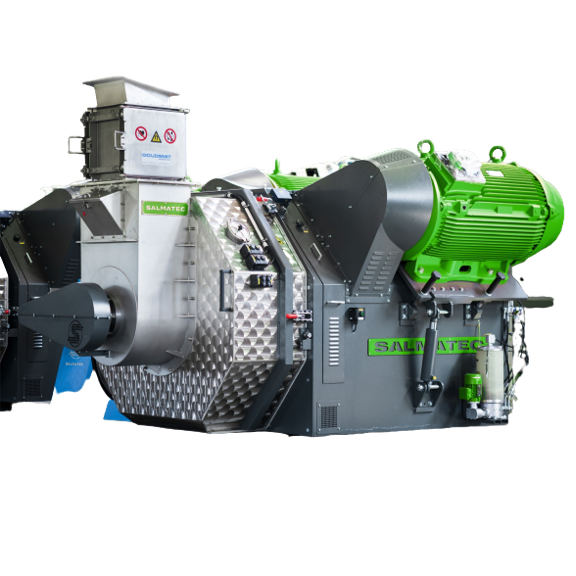

High-capacity ring-die pellet mill for animal feed production

Optimize your high-capacity feed production with this pell...

Laboratory pellet press for testing and formulation

Achieve precise pellet formulation and performance testing with versa...

Pellet mill for noise-reduced pelleting

Optimize production with a pellet mill designed to minimize noise and enhance lubri...

High-capacity pellet crumbler

Achieve precise pellet size reduction with this high-capacity solution, designed for effortles...

Pellet mills for feed, plastics, and industrial products

Optimize pelleting output across diverse materials with precisio...

High-capacity pelletizer for oilseed meal processing

Maximize throughput and ensure consistency in your pelleting process...

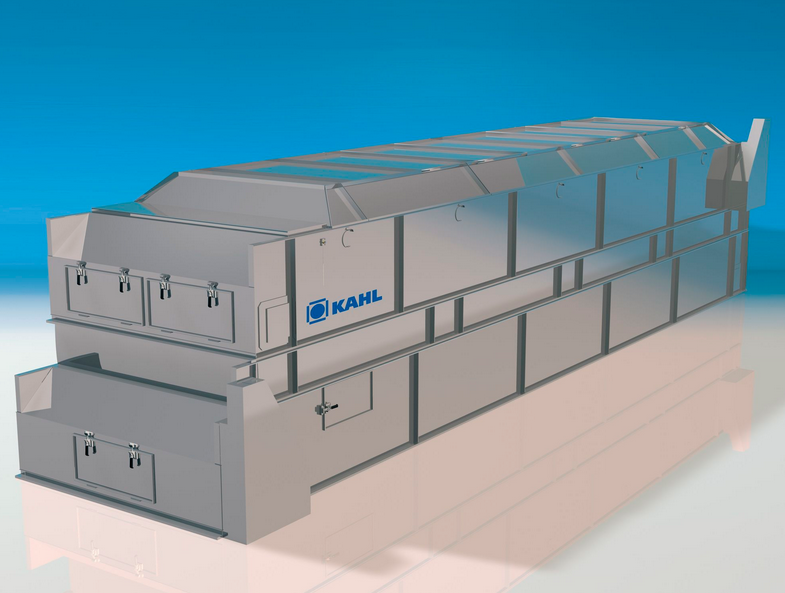

Counter flow cooler for feed pellet cooling

Optimize the cooling process of your feed pellets with precision, ensuring uni...

Pellet mill for powdery product processing

Transform powdery materials into durable pellets with precision and efficiency,...

Pellet mill for powdery animal feed products

Maximize plant efficiency and product quality with a versatile pelleting solu...

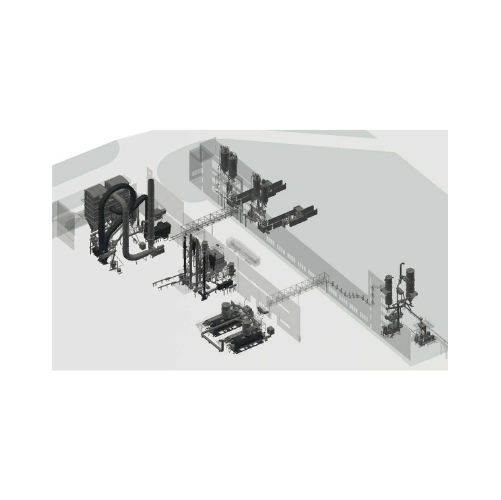

Complete pellet line

Large industries are shifting towards more environment-friendly technology, such as recycling wastes and...

Industrial pellet mill

At the industrial level, the application areas of pellets range widely in fields such as feeds, biomas...

Pelleting line for manure fertilizer

Manure fertilizer needs to be made marketable by making them visually attractive, with...

Continuous pellet cooler

Cooling is a very important and critical process for feed hygiene and pellet durability index. Pelle...

Counterflow pellet cooler

Food and feed industries require the highest standards of hygiene and sanitation. This entails fre...

Pelleting press for feed and petfood

The production of agricultural feed and pet food products requires machines and plants...

Pelleting press for biomass

Utilization of biomass for energy and other applications requires consistent and reliable compac...

Pelleting press with overhead drive

Production of certain pelletized products requires working with output products of a pa...

Hygienic pelleting press

The production of pelletized or granularized food products requires hygienic presses designed for hi...

Belt dryer/cooler for pellets and granules

Many industries that process materials in pellet, powder, or crumble form need ...

Small scale pelleting press

Many industries require reliable pelletizing equipment with smaller scale production capacities....

Process automation for feed mills

Optimize your feed production line by seamlessly integrating advanced process automation ...

Compact laboratory mixer for high-shear granulation

Streamline your R&D processes with advanced mixing and granulati...

Retentioner for animal feed safety enhancement

Enhance your feed production line with a retention system designed for unif...

Wheat processing systems for industrial applications

Maximize efficiency in wheat processing with a system designed for p...

Organic soybean feed extruder

Soybeans are an essential ingredient in the creation of protein-rich animal feed. To achieve h...

Micro powder dosing system

Micro dosing of powders and small components can be a major obstruction in the production process...

Evaporator for manure fertilizer

Traditionally, liquid manure processing can lose some important nutrients. An efficient ful...

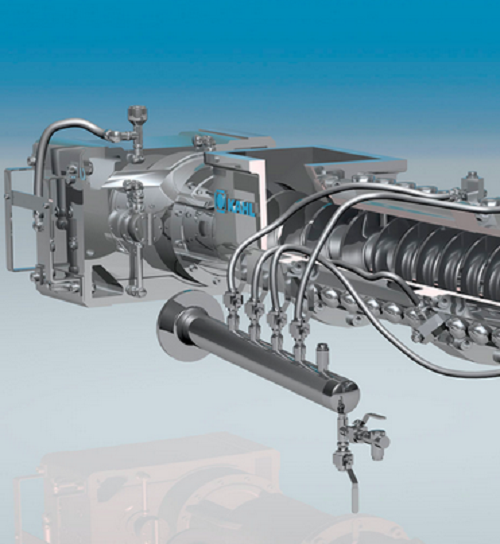

Annular gap expander for compound feed

Compound feed processing often requires a means of kneading and mixing input substra...

Belt dryer for wood

Processing of wood and biomass into pellets or other volume reduced products requires careful and consist...

Product intake solutions for feed processing

Optimize your feed production with efficient material intake systems, ensurin...

High-throughput hammer mill for animal feed production

Ideal for high-throughput operations, this hammer mill ensures pre...