Making Molasses

Find innovative production technology for making molasses and connect directly with world-leading specialists

Molasses production has been popular worldwide since the discovery of the Americas when sugar cane was introduced by the Spanish and its pressed boiled juice was used to make rum. Nowadays, the most common molasses comes from sugar cane and sugar beet. Depending on the source and extraction process, you can use molasses to produce ethanol, animal feed, food, fermentation products, and many others.

Tell us about your production challenge

Molasses production is a byproduct of the sugar industry.

Molasses or treacle as is known in the UK, is a byproduct of the sugar industry. Obtained after the crystallization of sugar from sugar cane or sugar beet. The process of making molasses as a byproduct differs in some steps from extracting the juice from the cane or the beet.

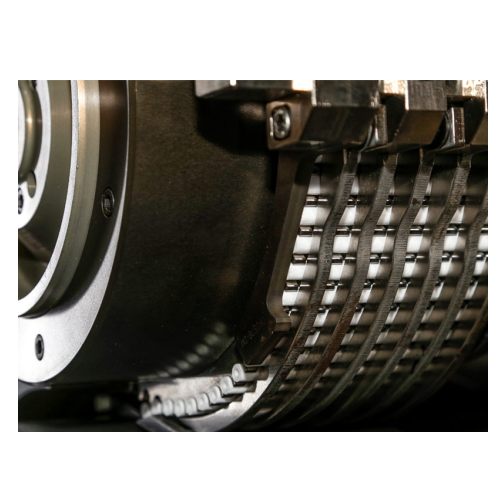

Sugar cane passes through crushing mills to compress the sugar cane fiber and extracts a juice that will go to clarifiers, then into evaporators or boilers to evaporate the water and obtain a thicker liquid, which will pass through high-speed centrifuges to separate the viscous liquid from the raw sugar crystals. Sugar beet passes through cutters, then they are mixed with water in rotative drums, producing a juice that is then heated and centrifugated to separate the sugar crystals from the molasses.

After boiling the molasses for the third time, there is no sugar left to crystallize in the process.

Molasses production can have different outputs, depending on the source, the quality you want to get, or the end use. From the first crystallization or boiling process, you will get A molasses, a light syrup that has between 80 to 85% of dry matter (DM) content. The second crystallization will give you B molasses or dark molasses, with a lower content of sugar. The third boiling will give you C molasses, also known as blackstrap molasses or treacle, which is the final molasses residue since sugar can not be crystallized further from this final syrup.

The final molasses is used in many industrial processes, majorly in the animal feed, distilled liquor, and biofuel industries. You can use the A and B molasses in food preparations if it is derived from sugar cane. There are other uses in the pharmaceutical and biotechnology sectors for sugarcane and sugarbeet molasses with additional processes involved.

Molasses is used for multiple purposes, with many industries upcycling this byproduct and contributing to the sustainable development goals (SDGs).

The animal feed industry uses molasses from sugar cane and sugar beet whether for direct feeding to provide energy to ruminants, (and occasionally pigs and poultry as well), sometimes mixing it with dry feed ingredients. Or for the pelleting of compound feeds, where molasses is used for binding together all the ingredients and improving palatability.

Molasses production is also greatly used in distilleries to produce alcohol, such as rum, as well as bioethanol to replace fossil fuels. The food industry uses them also to grow yeast, make sauces, sweets, canned food, and more. The biotechnology and chemical industries are using molasses-based processes, such as fermentation, dilution, yeast propagation, and distillation, to develop new products and contribute to the SDGs.

Processing steps involved in molasses making

Which molasses technology do you need?

Continuous mixers for feed mill applications

Optimize your liquid incorporation process with continuous mixers that ensure...

High capacity filling line for jars and bottles

Need to streamline your packaging line? This high-capacity solution proces...

Large container filling line

Optimize your production line with a seamless solution for efficiently filling large containers...

2-head liquid and viscous product filling system

Streamline your filling operations with precision and versatility designe...

Mechanical conveying systems for bulk solids

Optimize your bulk material processes with advanced mechanical conveying syst...

Combiner for multisegment filters

Optimize high-speed filter production with cutting-edge technology designed for seamless ...

Combiner for next generation heat-not-burn products

Streamline your next-generation tobacco product assembly with precisi...

Industrial evaporators for diverse applications

Maximize energy efficiency and reduce operational costs with cutting-edge ...

Percolation extractor for high-volume vegetable protein extraction

Optimize extraction efficiency across diverse materi...

Guillotine cutter for tobacco and botanical materials

Achieve precision cuts in small batches of tobacco, molasses, and b...

Tobacco strips conditioning cylinder

Achieve optimal loosening and moisture application for tobacco processing with an adva...

Industrial cutter for tobacco strips and stems

Achieve precision and consistency in your tobacco production with a cutting...

Casing and flavor preparation kitchens for tobacco industry

Enhance your tobacco product versatility with precision-engi...

Standard starch viscometer for gelatinization analysis

Ensure precise gelatinization property measurement with real-time ...

Self-priming centrifugal pump for entrained air handling

Effortlessly manage entrained air and foam in fluid processing w...

Wrapper and cartoner for e-commerce packaging

Streamline your packaging line with efficient cartoning and wrapping solutio...

Cartoner for tobacco and hemp products

Streamline your production line with high-speed cartoning and packaging for cigars, ...

Flow wrapper for molasses products

Optimize your high-speed packaging line with a flow wrapper that efficiently packs flavo...

Stand-up pouch packer for molasses

Optimize your tobacco molasses production with high-speed pouch packing, designed to mai...