Combiner for next generation heat-not-burn products

Streamline your next-generation tobacco product assembly with precision combining technology, ensuring seamless integration and high-speed production for complex product lines.

Combines and Assembles Tobacco Products

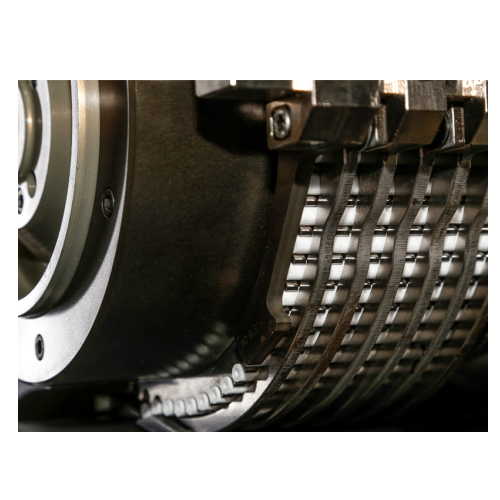

The MC Combiner for Next Generation Products is an engineered solution designed by G.D S.p.A, tailored for the dynamic needs of tobacco manufacturers. This equipment excels in combining and assembling process lines for heat-not-burn, vaporizers, and modern oral tobacco products, with a focus on high-speed, continuous operations.

Utilizing advanced flow automation and buffering systems, it ensures steady and efficient production, balancing line throughput with precision. Capable of processing a wide range of end-products including HeatSticks, Vaporizer Pods, and Snus Pouches, the MC Combiner is versatile in its application scope. It can seamlessly integrate with existing tray filling and unloading systems for smoother operational flow.

Engineered for high-efficiency production lines, the MC Combiner supports sustainable operations by optimizing energy consumption. Its modular design allows for easy customization, ensuring compatibility with various production requirements. The equipment includes PLC-controlled systems for enhanced automation and remote monitoring capabilities, promoting effortless oversight and control.

Constructed with robust materials suitable for tobacco processing conditions, the MC Combiner offers durability against wear and corrosion, aligning with industry standards for quality and safety. Maintenance is simplified with accessible design features, and G.D S.p.A provides engineering support for tailored solutions, ensuring the equipment meets specific operational needs and compliance requirements.

Benefits

- Enhances production efficiency through high-speed combining, reducing processing time.

- Minimizes energy costs with optimized motor control systems.

- Integrates seamlessly into existing tobacco production lines, improving workflow consistency.

- Reduces maintenance downtime with a user-friendly, accessible design.

- Supports flexible production needs with customizable configurations and engineering support.

- Applications

- Heat-not-burn, Filters, Molasses, Tobacco, Modern oral, Cigarettes, Cigars, Hybrid, Vapour, Snus, Cigarillos

- End products

- Cigar blunts, Filter rods, Mini cigars, Cigarette tubes, Snus pouches, Heated tobacco units, Flavored filters, Tobacco capsules, Molasses blocks, Heatsticks, Vaporizer pods

- Steps before

- Tray Filling, Cartridge Assembly

- Steps after

- Packing, Wrapping, Cartoning, E-cig Filling

- Input ingredients

- cigarettes, filters, filter rods

- Output ingredients

- heat-not-burn products

- Market info

- G.D (Coesia Group) is renowned for designing and manufacturing high-precision automatic machines, with expertise in tobacco processing and packaging solutions, reflecting a strong reputation for quality and innovation in industrial machinery.

- Speed

- 10, 000 ppm

- Automation

- Combiner for Next Generation Products

- Linked Machines

- T10, FTU

- Working mechanism

- Combining technology

- Integrated steps

- Cartridge assembly, flow automation

- Batch vs. continuous operation

- Batch

- Automation level

- High

- CIP/SIP

- CIP

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Combining method

- Cartridge Assembly

- Product type

- Cigarettes/Filters

- CE marking

- Yes

- FDA compliance

- Yes

- FDA materials

- Yes

- GMP Compliance

- Yes

- Combining technology

- Heat-not-burn

- Industry application

- Tobacco