Making Sugar

Find innovative production technology for making sugar and connect directly with world-leading specialists

Sugar is the fuel that drives photosynthesis in plants. The leafy organisms constantly convert water and carbon dioxide into glucose. But it takes manufacturers specialized sugar processing technology to extract the sweet crystals from them. Today, most sugar products are derived either from sugarcane or sugar beet.

Stories about sugar

Select your sugar process

Tell us about your production challenge

Apply shock-liming sulphitation to clarify the juice

The shock-liming sulphitation process produces juice with a high rate of clarity. Sulfur dioxide (SO2) and lime remove non-sugars from the liquid. This is generally different to the juice that comes from fruits as that usually has a low rate of clarity.

Heat the juice to 70°C-75°C for around 10 seconds to raise its pH level between 9.2 and 9.5. After neutralization with sulfur dioxide, the pH lowers to about 7.0.

Concentrate sucrose to 70 °Bx with sugar processing technology

Evaporate water in the juice of crushed sugar cane to raise the sucrose concentration. Crystallization occurs when the water content decreases to leave a minimum 70 Brix.

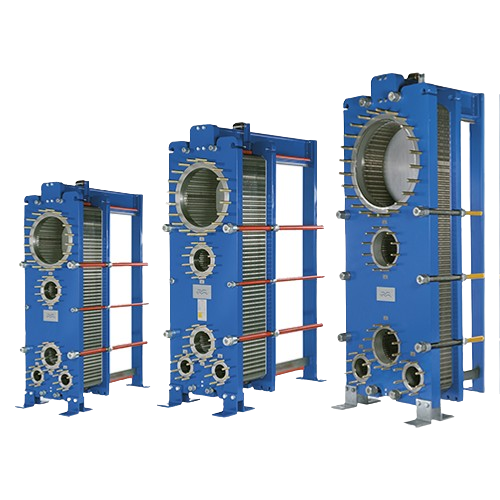

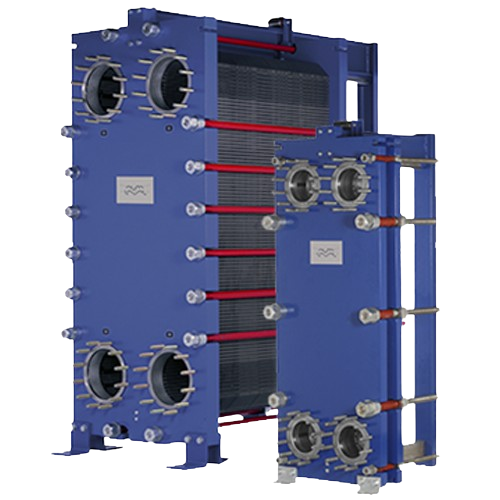

A multiple-effect evaporator passes the clarified juice through a heat exchanger to gradually lower moisture content. Steam from water evaporated in one effect is used to heat the subsequent effect. Steam is then collected in the condensation unit, ready to be reused.

Steam-spray the massecuite to release sugar crystals after centrifugation

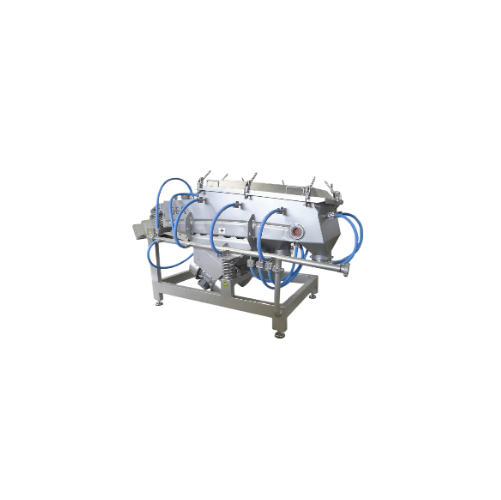

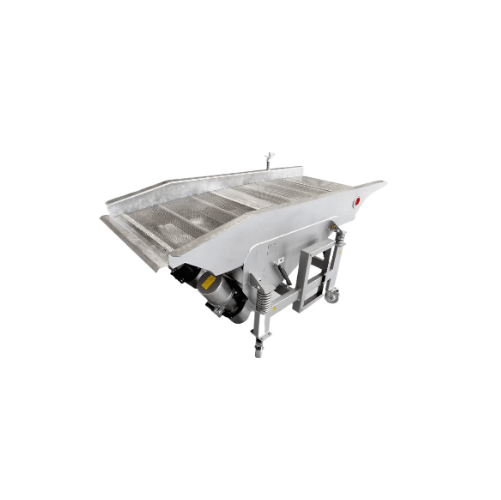

Sugar crystals trapped in the massecuite after the centrifugation process present a challenge. Spraying the mesh basket achieves some recovery, but many crystals may be washed out.

Instead, treat the massecuite with steam spray post-centrifugation process to facilitate the drainage of molasses and retain the crystals. The characteristic time for heat diffusion into the molasses is about 0.6 sec.

Processing steps involved in sugar making

Which sugar technology do you need?

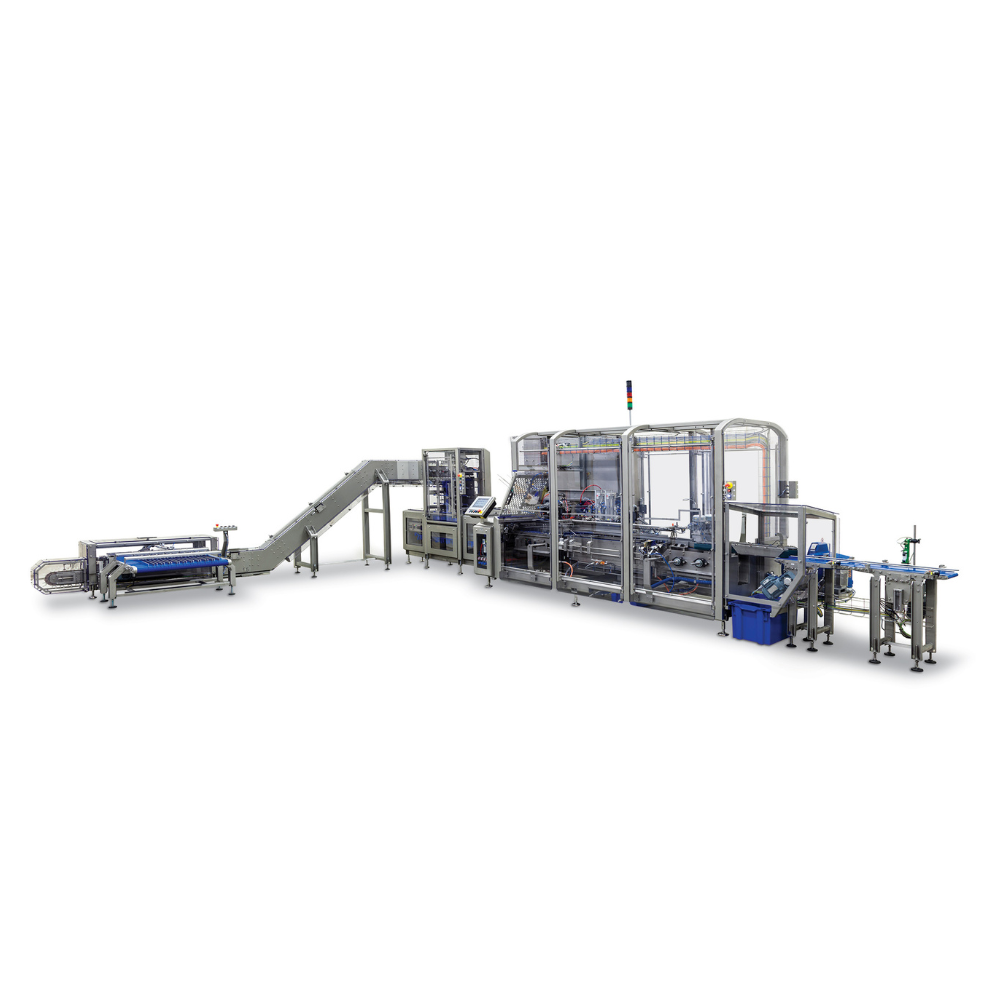

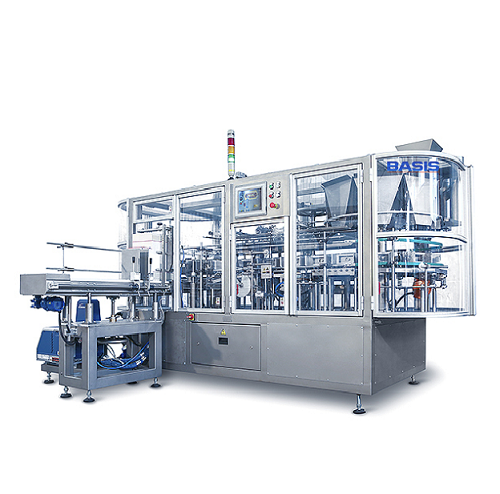

Medium-speed end load cartoner for food and beverage packaging

Streamline your packaging line with versatile cartoning c...

Intermittent end load cartoner for baked goods and snacks

Optimize your packaging line with an efficient, space-saving c...

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

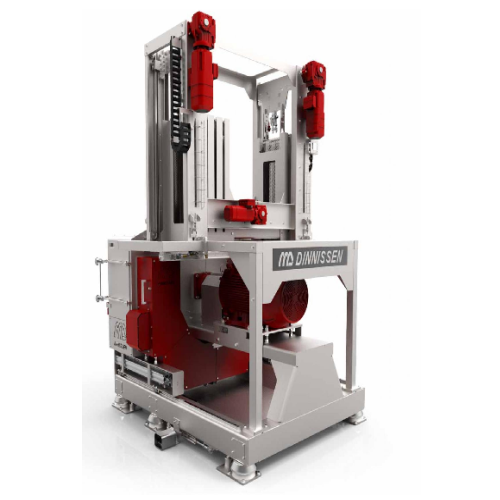

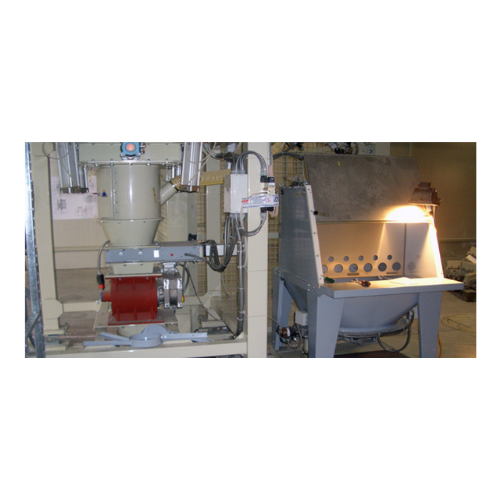

Industrial powder security screening and de-agglomeration

Ensure product purity by efficiently screening and de-agglomer...

Powder sifters for industrial applications

Optimize powder consistency and enhance production flow with advanced sifting t...

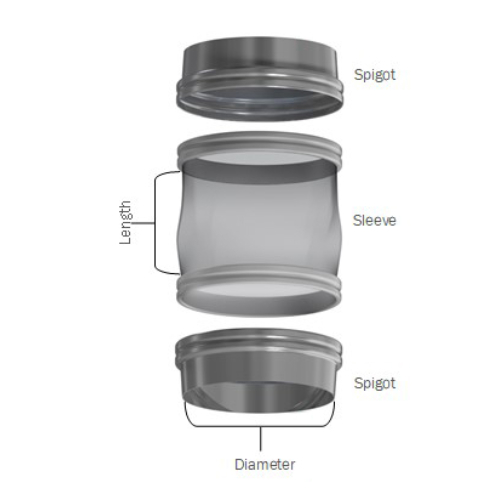

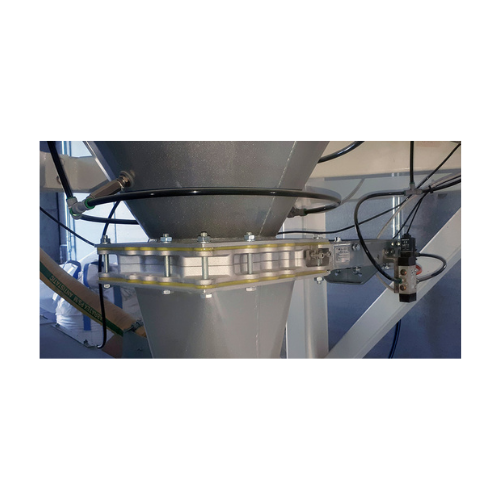

Flexible connector for bulk powder manufacturing

Eliminate leakage and enhance hygiene in your powder processing with a sn...

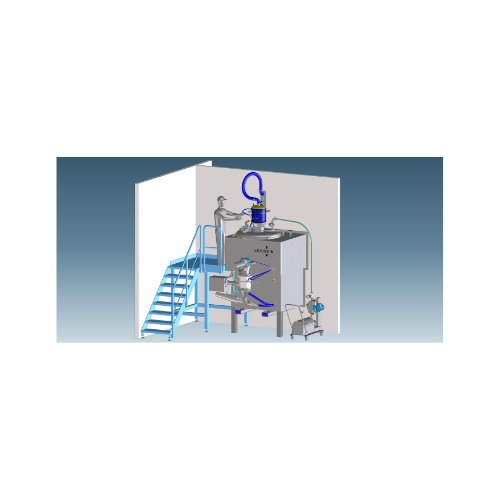

Powder and liquid mixing system for food and life sciences

Achieve rapid and homogeneous dissolution of large quantities...

Efficient powder and granulate flight conveyors

Elevate your production efficiency with our cutting-edge flight conveyors,...

Energy-efficient impact classifier for superfine grinding

Achieve precise superfine grinding with energy efficiency, per...

Particle size and shape analyzer

Achieve precise particle size and shape analysis from 0.8 μm to 8 mm with exceptional speed...

Vibratory bowl feeder for bulk items

When precision and speed are crucial, ensure your production line efficiently handles ...

Centrifugal bowl feeder for high-speed bulk item feeding

Optimize your production line with high-speed feeding of diverse...

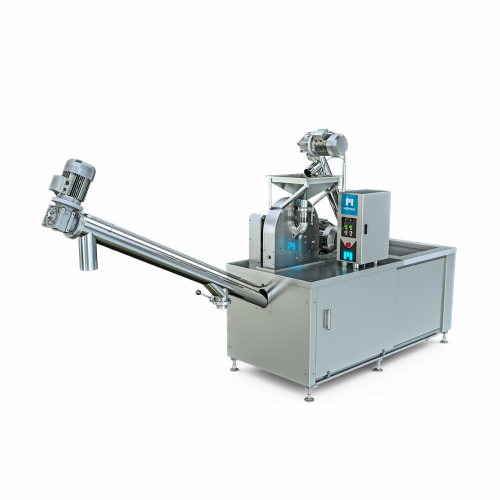

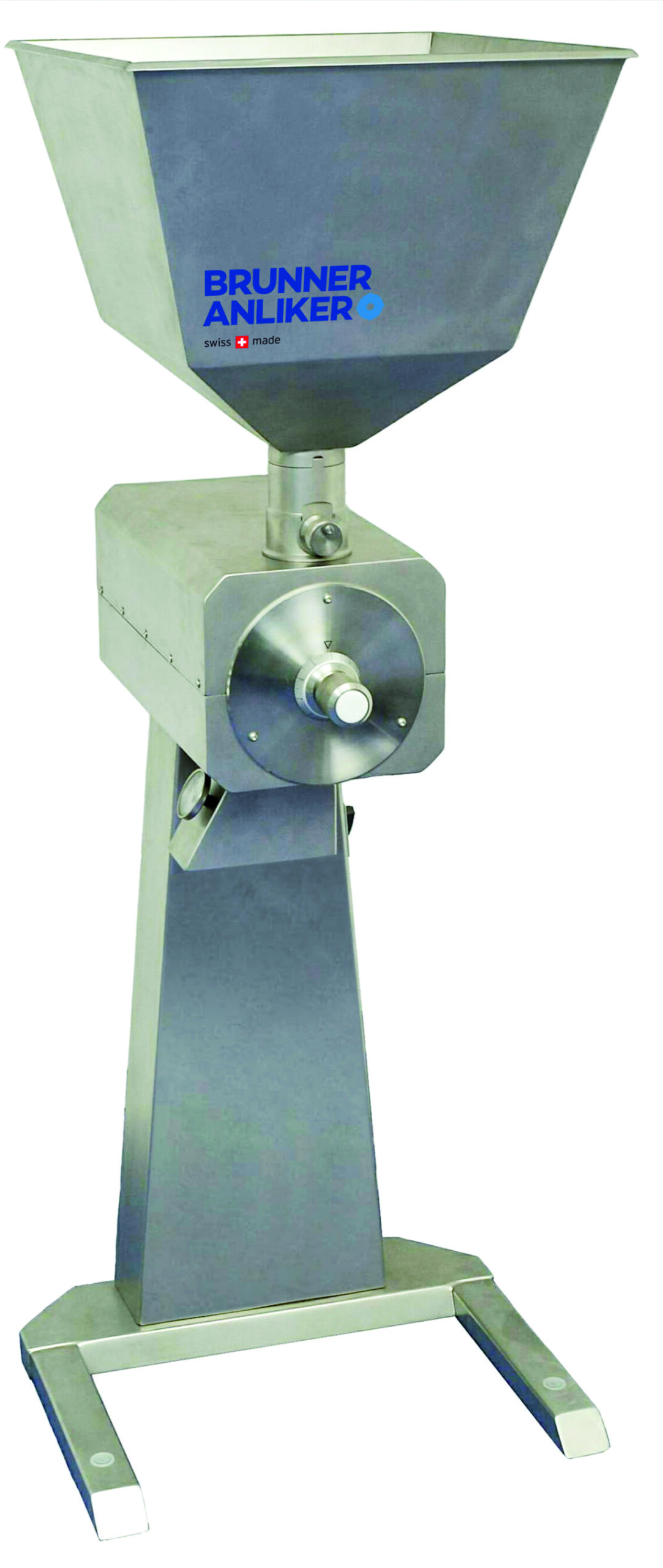

Industrial sugar powder mill

Achieve precise sugar granulation with a high-speed mill designed for continuous production, en...

Duplex refiner/conche for chocolate production

Effortlessly transform cocoa, sugar, and other ingredients into smooth, fin...

Mixing granulator for pharmaceutical and cosmetic industries

Achieve precise granulation and uniform mixing for high-qua...

Continuous sugar dissolver for syrup production

Effortlessly convert crystal sugar into high-quality syrup with a system d...

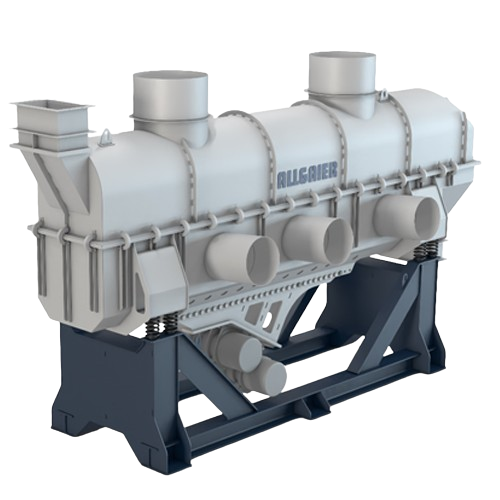

Tumbler screener for multi-deck screening in powders and granules

Achieve precise separation and de-dusting of powders ...

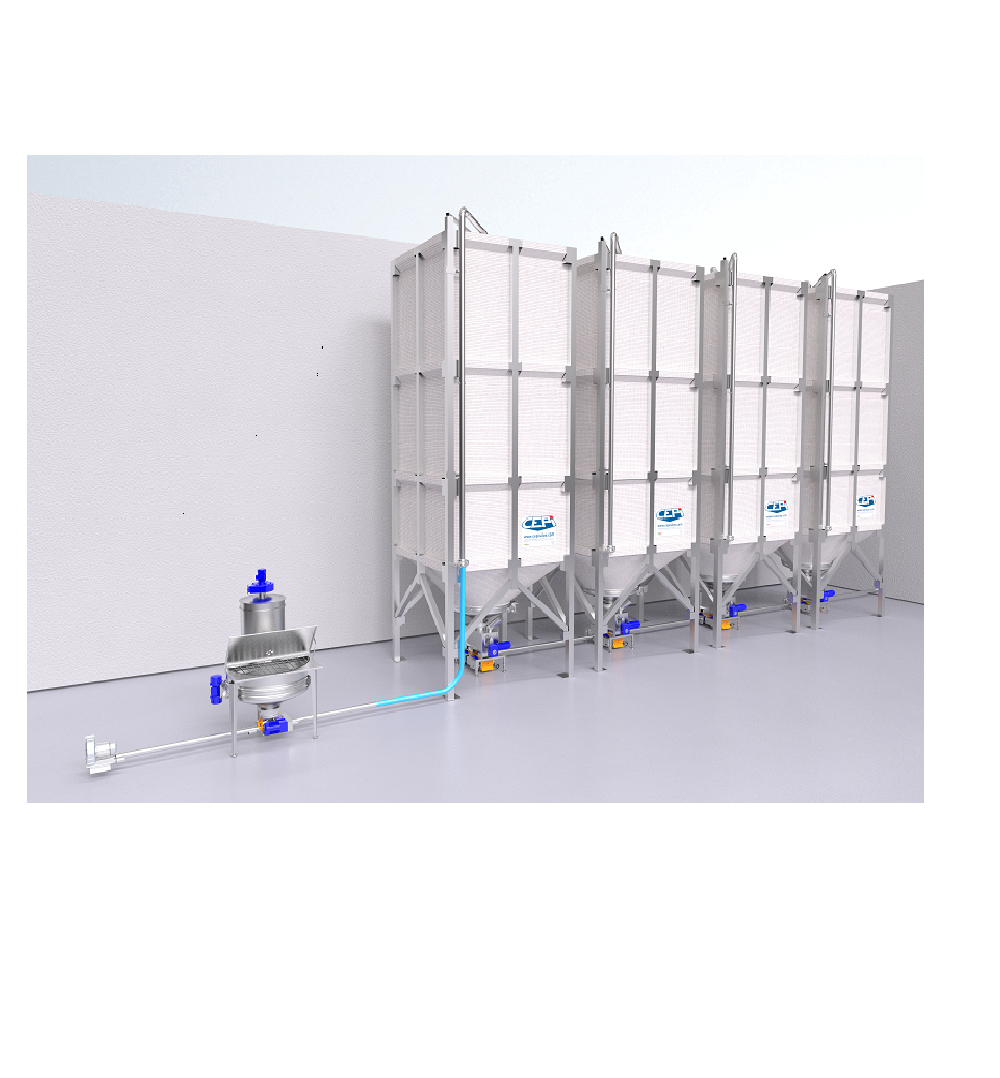

Industrial silos for powdered and granulated products

Optimize your storage and material flow for powdered and granulated...

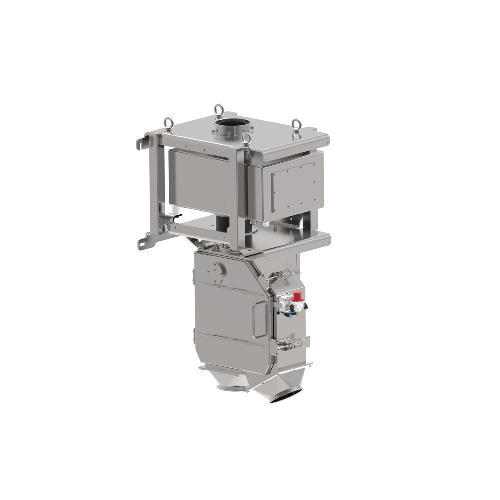

Bag dump station for handling solid foodstuffs

Efficiently manage manual dosing of solid foodstuffs and powders with this ...

Big bag unloading station for solid materials

Streamline your production line by efficiently handling and dosing bulk soli...

Big bag unloading station for solids handling

Optimize bulk solid ingredient handling with this station, designed to strea...

Micro ingredients loading station for solid additives

Optimize precision dosing and ensure smooth transfer of powdered in...

Buffer tanks for powdered or granulated solids storage

Enhance your production line with buffer tanks designed for precis...

Powder blender for liquid mixing applications

Optimize your process with a compact blender designed to efficiently dissolv...

Standard batch mixer for salt and citric acid mixing

Achieve perfectly homogeneous blends of salts, sugars, and challengi...

Brine and syrup mixing system

Achieve precise mixing of brines, syrups, and challenging additives with advanced automation, ...

Sugar dissolving system for industrial applications

Efficiently dissolve sugar and low-viscosity blends to achieve perfec...

Industrial powder grinder

Achieve precise particle size reduction and classification with advanced equipment designed for co...

High shear impact mixer for agglomeration and dispersion

Achieve precise homogeneity and efficient agglomeration with a h...

Powder mixing systems

Optimize your production line with precision powder mixing systems that ensure uniformity, enhance prod...

Choppers and disintegrators for industrial size reduction

Enhance your production efficiency by mastering size reduction...

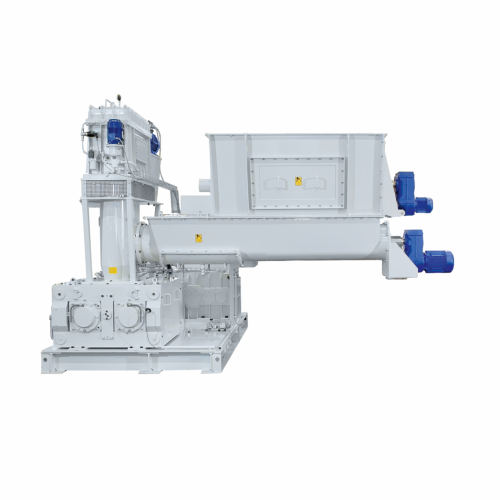

Compactors and granulators for powdery products

Transform loose powders into dense, free-flowing granules that enhance han...

Drying systems for powders and bulk solids

Enhance your production line with precise control of moisture content in powder...

Lab-scale powder processing system

Achieve precise control in ultra-small batch processing with a versatile modular system,...

Powder characteristic evaluation

Ensure precise powder analysis and testing in your laboratory to optimize production qualit...

Cip/sip cleaning for solids processing systems

Ensure seamless transitions and maintain hygienic production environments w...

Containment solutions for hazardous material processing

Ensure safe and efficient processing of hazardous materials with ...

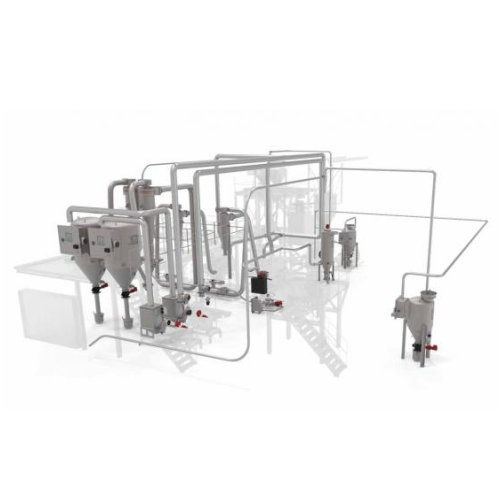

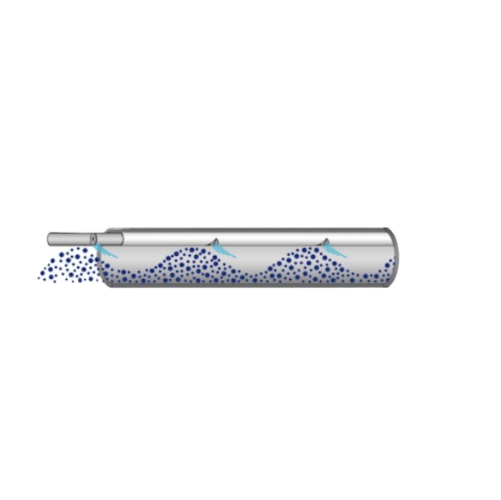

Pneumatic conveying system for bulk material handling

Efficiently transport bulk materials with precision through pneumat...

Industrial pre-crusher for coarse crushing

Optimize your production line by efficiently transforming clumped materials int...

Table roller mills for mineral raw material comminution

Achieve precise mineral raw material comminution and energy-effic...

Conical screw mixer for powder blending

Achieve precise and homogeneous blending with the conical screw mixer, ensuring uni...

Ultra-fine powder flash drying system

Achieve rapid moisture removal and particle refinement with this integrated system, d...

Fluidised bed opposed jet mill for fine particle processing

Achieve precise and consistent particle sizes with high-spee...

Roller press for fine-grained material compaction

Achieve optimal density and stability in your solid press agglomerates ...

High-pressure roller compactors for chemical, food, and minerals industries

Achieve precise particle compaction and br...

Multiprocessing system for flexible research and production

Optimize your process development with a versatile system th...

Pelleting and spheronizing equipment for chemical granulates

Optimize your production line with versatile pelleting and ...

Low-dust granulator for plastic parts recycling

Achieve efficient comminution with minimized dust generation, ideal for pr...

Industrial granulator for high-throughput plastic recycling

Facing challenges in efficiently recycling high-volume plast...

High-speed pulverizer for carbon black production

Achieve consistent particle size and optimal homogenization with high-s...

High-pressure roller mill for medium-fine crushing

Achieve precise granule distribution in medium-fine crushing applicati...

Spiral jet mill for superfine powder production

Achieve consistent ultra-fine powder with precise particle size control, c...

Fluidised bed opposed jet mill for ultrafine powder production

Achieve contamination-free ultrafine powder milling with ...

Sugar grinding and recrystallization system

Optimize your sugar production with a system that integrates grinding and recr...

Versatile fine impact mill for soft materials

Achieve precision grinding with flexibility for a wide range of materials, e...

Flake crusher for hygroscopic substances and lumped salts

Efficiently turn fragile, aggregated materials into manageable...

Heavy-duty shredder for difficult materials

Struggling with stubborn materials that resist conventional shredding? This ro...

Ultrafine classifier for toner and pigments

Achieve unparalleled precision in classifying fine powders essential for high-...

Ultrafine air classifier for powder separation

Achieve precise particle separation with technology designed to enhance you...

Ultrafine classifier for soft to medium-hard mineral processing

Achieve exceptional particle precision with an ultrafine...

Discharge systems for difficult bulk materials

Achieve seamless bulk material discharge with our advanced systems that eff...

Ultrafine grinding mill for calcium carbonate slurries

Achieve precise particle size distribution in your mineral slurrie...

Ball mill for dry comminution of hard materials

Achieve ultrafine particle sizes and precise material breakdown with this ...

Classifier mill for ultrafine grinding

Achieve precise particle size distribution and contamination-free processing with th...

Air jet sieve for particle size analysis

Achieve precise particle size distribution effortlessly for your powders, ensuring...

X-ray inspection system for detecting foreign objects in food products

Ensure product safety and quality by detecting e...

Integrated packaging system for valve and tubular film bags

Achieve precision and efficiency in your packaging line with...

Vacuum conveyor for hygienic material transfer

For operations demanding swift, dust-free material handling, this solution ...

Stainless steel intermediate bulk containers for pharmaceutical use

Ensure safe, efficient transport and handling of po...

Conical mills for size reduction in pharmaceutical production

Achieve precise particle size control with an innovative m...

High capacity conical mill for powder processing

Optimize your milling process with a versatile solution that ensures prec...

Industrial container lifting system

Optimize your production line with a versatile lifting solution designed to safely hand...

Industrial sugar grinding mill

Optimize sugar fineness with a compact grinding solution, ensuring high-speed operation and l...

Chocolate refiner and conche solution

Elevate your chocolate production with a versatile solution that seamlessly integrate...

Industrial melting unit for chocolate and powders

Enhance your production efficiency by seamlessly melting and homogenizi...

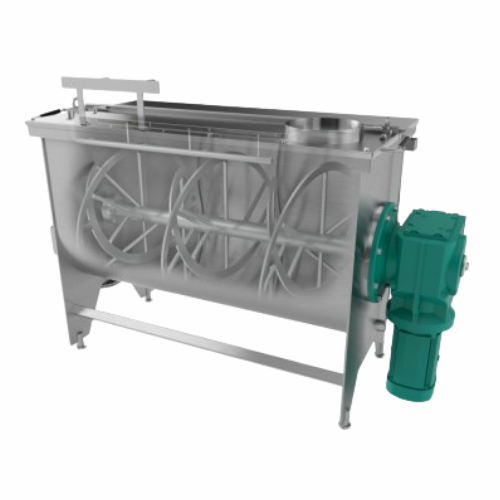

Ribbon blender for homogeneous blending of solids

Achieve perfectly consistent blends with a ribbon blender that ensures ...

Sampling valve for secure sample extraction

Ensure product quality by safely extracting representative samples without hal...

Industrial hydrogenation plant for pharmaceutical raw materials

Optimize your hydrogenation processes with a modular pla...

High-shear mixer granulator for pharmaceutical production start-up

Effortlessly achieve optimal granule consistency and...

Industrial pneumatic conveying system for powders and granulates

Achieve hygienic and dust-free transport of powders and...

Micro dosing system for precise powder weighing

Achieve unparalleled dosing accuracy in your production line with a system...

Hammer mill with automatic screen exchange

Optimize your milling operations with a high-speed solution that ensures seamle...

Industrial hammer mill for grinding and sifting

Ensure precise particle size reduction and consistent product quality with...

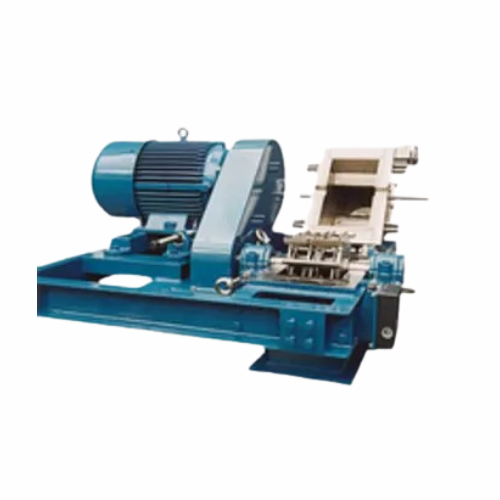

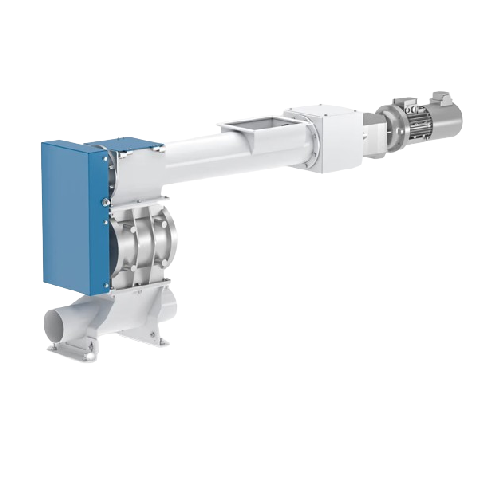

Mechanical horizontal conveyor for powders and granulates

Efficiently handle and transport your delicate powders and gra...

Vertical transport for bulk goods

Efficiently move bulk goods vertically with minimal energy usage, ensuring seamless integ...

Industrial centrifugal sifter for solid particulate materials

Quickly and accurately sift a wide range of powders and gr...

Weigh filler for bulk quantities 2-20kg

Optimizing your filling process with precision, this equipment handles bulk quantit...

Weight filler for small batches in explosive areas

Efficiently handle and weigh small batch products with precision, even...

High-performance checkweigher for pharmaceutical tablet cartons

Achieve precision weighing at speeds up to 500 units per...

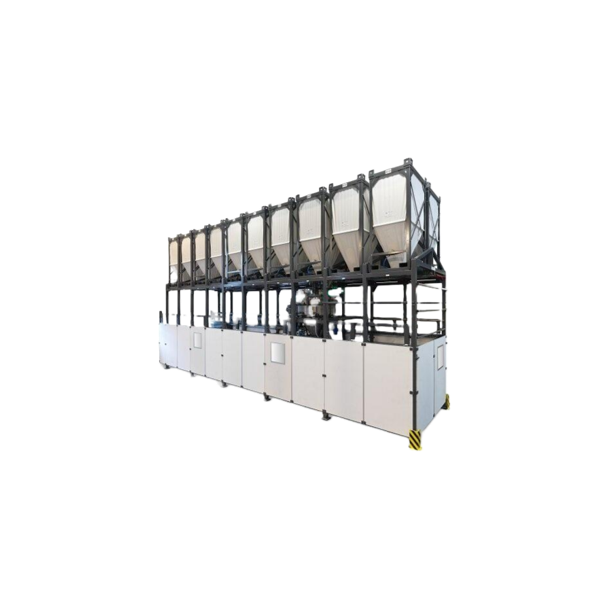

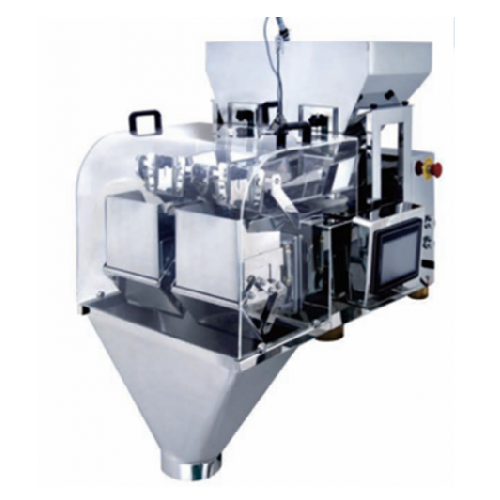

Batch weighing system for precise raw ingredient mixing

Optimize your confectionery production with a precise batch weigh...

Industrial sugar melter

Efficiently melt and mix sugar with precision using a gas-fired batch cooker designed for optimal hea...

Powder dissolution unit for beverage production

Achieve precise and rapid dissolution of powders like sugar and acids, opt...

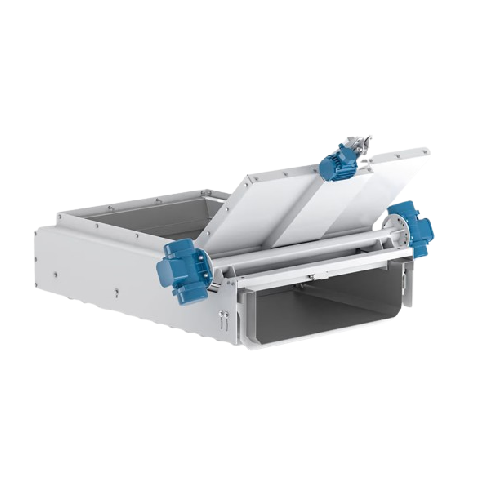

Grain sifter for milling applications

Optimize your grain processing by efficiently sifting and sorting a variety of produc...

Industrial sieving solution for powders and granulates

Ensure top sanitation and food safety in your production line with...

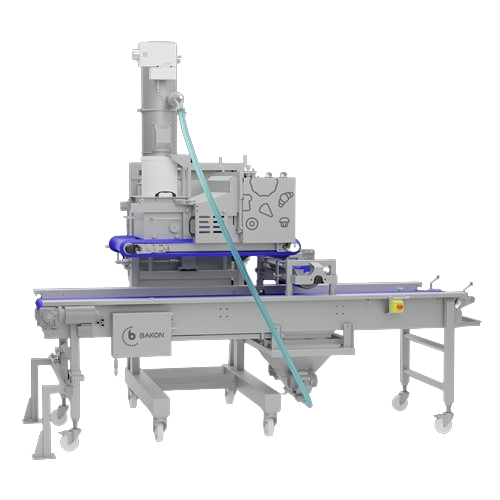

Vibration sprinkler for uniform dough decoration

Elevate your baked goods with precise, uniform decoration using a vibrati...

Impact machine for milling applications

Optimize your grain processing with this versatile impact machine, designed to refi...

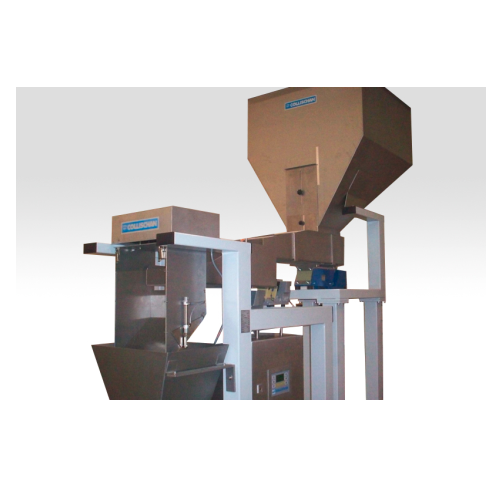

Weighing and receiving container for floury products

Achieve precise and consistent ingredient proportions with this syst...

Grain product plansifter

Optimize your grain processing with a magnetic drive plansifter that efficiently sifts and sorts a d...

Lab-scale twin screw extruder

Optimize your material testing and production efficiency with our versatile twin screw extrude...

Standard starch viscometer for gelatinization analysis

Ensure precise gelatinization property measurement with real-time ...

Digital torque viscometer for starch analysis

Experience rapid and precise starch gelatinization analysis with a compact, ...

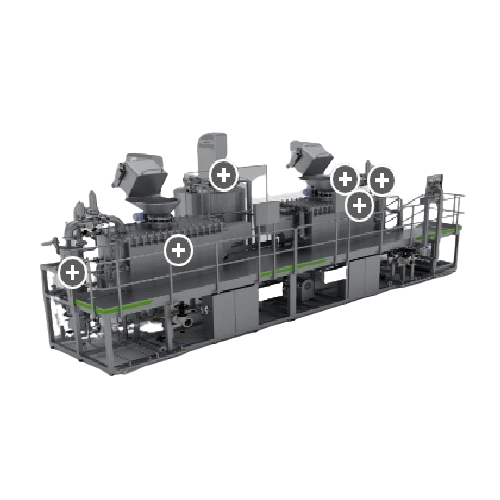

Material handling system for confectionery production

Optimize your production line with a system designed for efficient ...

Small twin screw extruder

Optimize your lab and pilot production with a versatile twin screw extruder, designed for precise ...

Lab- and pilot-scale twin screw extruders for small-scale production

Optimize extrusion techniques with lab and pilot-s...

Efficient topping strewer for bakery production lines

Enhance your product’s appeal and streamline topping applicat...

Industrial columns and towers for chemical processing

Optimize your chemical production with robust columns and towers, d...

Integrated pickup station for bagged products and big bags

Streamline the handling and transition of bulk materials with...

Advanced powder dosing system for continuous production

Achieve precise powder integration into your liquid processes, en...

Modular big bag discharge station for bulk material handling

Streamline your bulk material handling with a customizable ...

Dust-free docking collar for containers and bins

Achieve seamless, dust-free connections between containers and processing...

Bag feeding hopper for bulk solids

Optimize your material handling with a robust feeding hopper that seamlessly integrates ...

Dust-free big bag connection system for bulk solids

Eliminate dust and ensure reliable discharge with this vacuum docking...

Automated bulk material handling system

Ensure precise batch tracking and efficient handling of challenging bulk materials ...

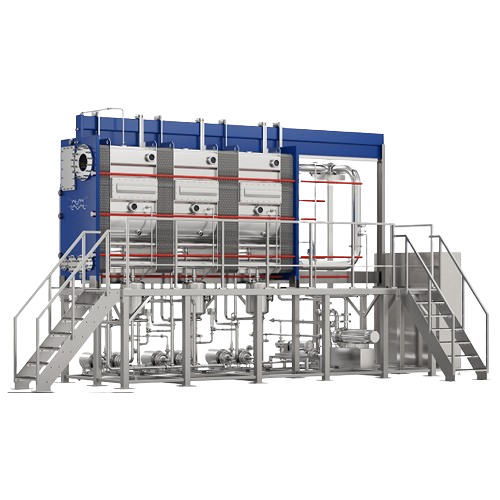

Aseptic cooking and filling line with two reactors

Streamline your production with a versatile line that combines high-ef...

Cross flow filtration for industrial liquid purification

Optimize your production process with advanced cross flow filtra...

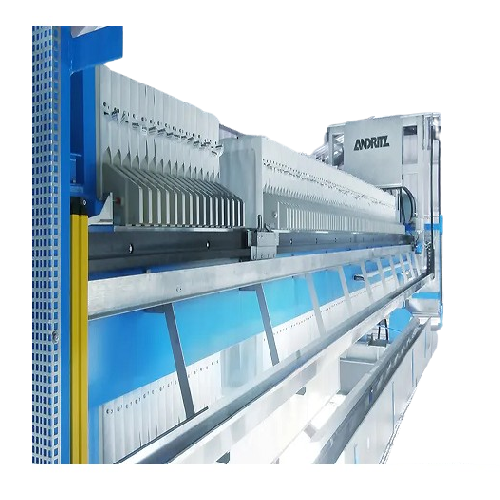

Industrial filter press for dewatering and filtration

Optimize your dewatering and filtration needs with a highly adaptab...

Mill sifter for precise bulk density and particle size distribution

Achieve precise particle size and uniform bulk dens...

Paddle dryer for industrial sludge

Achieve consistent drying and pasteurization of complex materials with this advanced pad...

High boiled sugar continuous batch cooker

Streamline your confectionery production with efficient high boiled sugar cookin...

Multi-fill powder filling system

Achieve precise and consistent filling for your powdered and granulated products with a mod...

Fluidized bed dryer for industrial materials

Enhance product quality and energy efficiency with fluidized bed dryers, opti...

Ultrafiltration and microfiltration module for low to medium viscosity products

Streamline the separation and concentr...

Ultrafiltration module for high-viscosity products

Achieve enhanced separation efficiency with a versatile module designe...

In-line filling system for various container sizes

Streamline your production with versatile in-line filling solutions th...

Industrial auger sack filler for large bags

Designed to efficiently fill large bags and sacks, this advanced filling machi...

Vertical form fill seal filling system for auger applications

Effortlessly integrate precise powder and granule filling ...

Climbing film plate evaporator for food industry

Efficiently concentrate heat-sensitive liquids while minimizing product e...

Rising film evaporator for concentration of viscous liquids

Effortlessly concentrate low-to-medium fouling and highly vi...

Plate surface condenser for vapour under vacuum

Experience high-efficiency condensation in space-constrained environments ...

Heat exchanger for fibrous and coarse particle fluids

For operations involving fibrous and coarse particle fluids, this a...

Vacuum conveyor for powder and granule transfer

Ensure efficient and contamination-free transfer of powders and granules w...

Powder filling machine for dry products

Achieve precision and consistency in filling dry powders and granules with a versat...

Automatic popcorn ball forming equipment

Streamline your snack production with high-speed, precise popcorn ball forming tec...

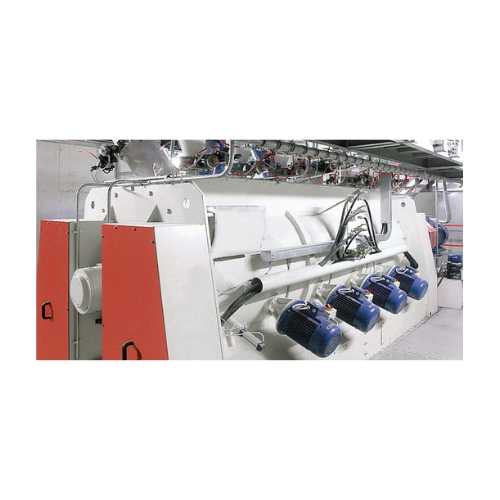

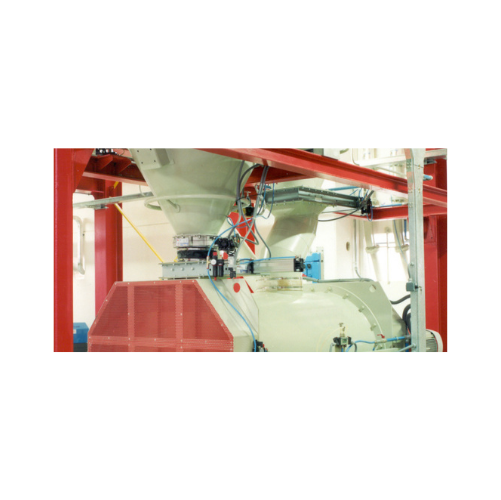

Granulated sugar storage and conveyance solutions

Optimize your sugar processing with versatile solutions for storage, pr...

Sugar syrup treatment system

Ensure your sugar syrups meet quality standards by eliminating impurities and maintaining optim...

Industrial mixing tanks for liquid, slurry, and gas dosing

Optimize your production with versatile mix tanks, designed t...

Flour and crumb feeders for breading and pre-dusting processes

Optimize your breading and pre-dusting operations with ad...

Cyclone filter for pneumatic conveying systems

Efficiently separate and filter airborne dust in pneumatic conveying lines,...

Self-cleaning silo filter

Ensure purity and compliance by trapping dust effectively during silo loading, while maintaining c...

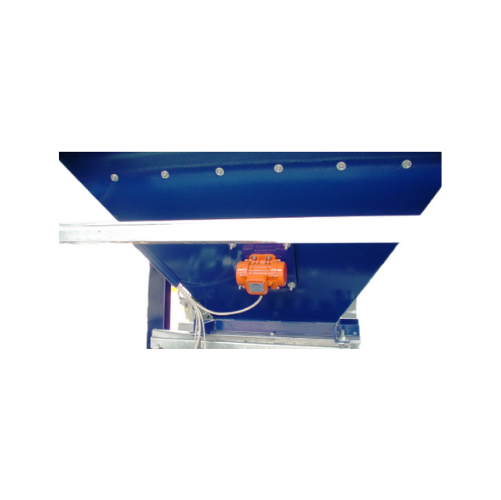

Industrial vibrating extractor for homogeneous product conveyance

Ensure consistent flow of dry bulk materials with a v...

Industrial sifters for beverage processing

Optimize your beverage production with precisely engineered sifters that ensure...

Vibrating sifter for chemical applications

Achieve precise particle separation with this vibrating sifter, ensuring optima...

Food product sifter

Ensure precise separation with vibratory sifters designed for continuous operation, delivering gentle han...

Industrial powder sifter with sanitary compliance

Optimize your powder processing with this versatile sifter, ensuring pr...

Continuous raw material distribution screw doser

Optimize your material flow with a screw doser designed for precise and c...

Big bag emptying station for bulk product handling

Streamline your bulk material handling with a station designed to effi...

Direct discharge descender for product handling

Efficiently transport granulated materials without compromising their inte...

Vibrating extractor for silo and hopper product distribution

Ensure consistent product flow and precise distribution fro...

Big bag emptying station for raw materials

Streamline your material handling process by efficiently lifting, emptying, and...

Lean phase pressure conveying for powder handling

Effortlessly transport and manage powdered materials with lean phase pr...

Vacuum powder sampler for particle size distribution control

Ensure precise quality control with a vacuum powder sampler...

Bulk storage silos for food products

Ensure optimal powder storage and handling with versatile silos designed for efficient...

Continuous motion packaging for short-cut pasta

Optimize your packing line with a high-speed solution designed for efficie...

Intermittent motion bulk packaging for pasta and granular products

Optimize your production line with precision packagi...

Bulk powder filler for food, dairy, and nutraceuticals

Optimize your bulk powder filling process with a system designed t...

Low care bulk powder fillers

Optimize your production efficiency by accurately filling flexible bulk containers with dry pow...

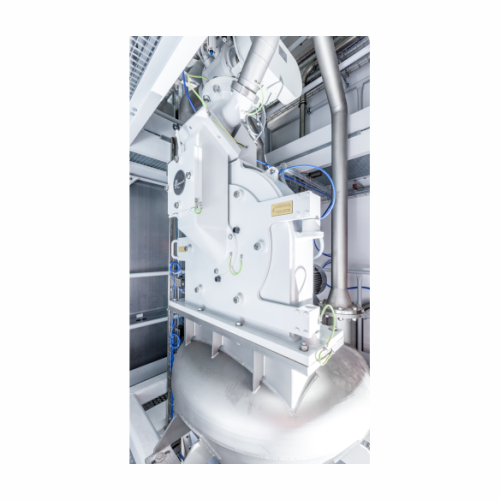

Industrial solution crystallization plants

Optimize your production with tailored crystallization systems designed for eff...

Plastic bag sealer for polyethylene bags

Achieve consistent hermetic sealing of polyethylene bags while preserving the inte...

Semi-automatic powder filling system for food products

Achieve precise and flexible filling for food powders and granules...

P-type ring dryer for thermally sensitive products

Optimize moisture control and prevent thermal degradation in your prod...

Industrial powder fillers for various containers

Optimize your packaging line with high-speed powder fillers that handle d...

Vibratory bottom discharge system for bulk materials

Ensure consistent flow of challenging bulk materials with a vibrator...

Rotary sifter for bulk material preparation

Ensure precise material preparation and protect downstream processes by integr...

Industrial rotary feeder for powder and agglomerates

Achieve seamless integration in your production line with a robust s...

Pta and Pet production systems

Maximize throughput while minimizing dust fines in your production of PTA and PET pellets wit...

Industrial discharge and dosing module

Optimize material flow and prevent blockages in silo discharge and dosing processes,...

Sampler for powdered and granular bulk materials

Ensure precise sampling of powdered and granular materials under varied o...

Sampler for free-flowing granular bulk materials

Efficient and precise sampling of granular bulk materials and coarse powd...

Dosing and conveying screw for dry bulk materials

Efficiently manage the precise dosing and conveying of dry, powder, and...

Fluidizing bed for bulk material discharge

Optimize your material flow with a fluidizing bed designed for seamless dischar...

A-type rotary feeder for powder and pelleted bulk materials

Ensure precise feeding and discharging of powdered and pelle...

Single-shaft ribbon blender for homogeneous mixing

Achieve high-quality, precise blending of delicate and temperature-sen...

Tanker loading bellow for dust-free bulk solids loading

Optimize tanker loading while minimizing dust emissions with this...

Bulk solids discharging and loading solution

Optimize your bulk material handling with equipment that ensures efficient an...

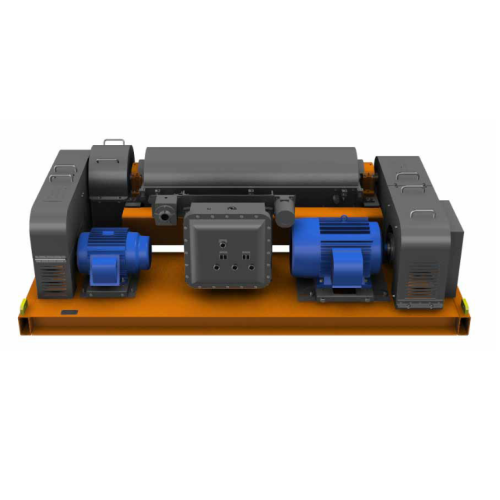

Pneumatic conveying system for bulk solids

Ensure efficient and dust-free transport of bulk materials with a pneumatic con...

Batch-type single shaft mixers with bomb-bay discharge

When you need rapid, residue-free discharge in your batch mixing p...

Industrial dust collection system for air filtration

Optimize air quality in your production line with this compact dust ...

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to ma...

Fit-frame butterfly valves for dry bulk solids

Achieve precise control and minimize contamination in your dry bulk materia...

Butterfly valves for powders and granules

Ensure precise flow control and reliable sealing for gravity-fed or pneumatic sy...

Butterfly valves for powder and granular material handling

Experience seamless material control with advanced butterfly ...

Industrial slide valve for heavy-duty applications

When managing gravity material flow in abrasive environments, achievin...

Membrane pressure relief valve for silos and bins

Ensure silo safety with our valve that instantly balances internal pres...

Low profile slide valve for controlling powder flow

Optimize your powder and granule flow management with precision-engin...

Slide valves for flow interception in powder and granular materials

Effectively manage the flow of powdery and granular...

Flap diverter valves for pneumatic conveying

Streamline material flow in your pneumatic conveying system by effortlessly r...

Diverter valves for pneumatic conveying lines

Experience precise flow control in pneumatic conveying with diverter valves ...

Drum-type diverter valves for pneumatic conveying

Optimize your pneumatic conveying system by effortlessly controlling th...

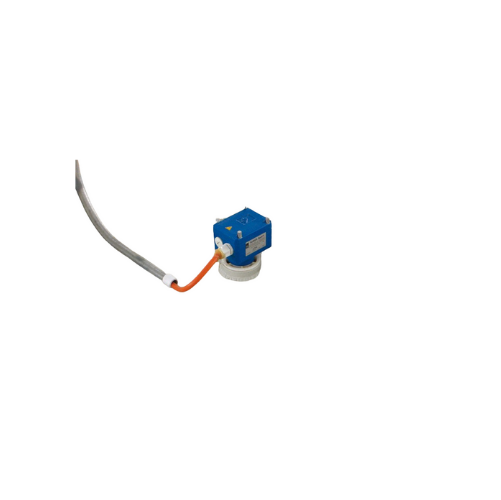

Vibro-aerators for bulk solids discharging

Optimize your powder flow and ensure consistent discharge with this advanced ae...

Silo overfill protection valves

When abnormal pressure threatens your silo’s integrity, reliable pressure relief becom...

Spring-loaded pressure relief valves for silo overfill protection

Ensure safety and prevent costly overfills with press...

Food-grade tubular screw conveyors

Ensure complete hygiene in your production line with these stainless steel tubular screw...

Food-grade stainless steel tubular screw conveyors

Ensure contamination-free material handling with our tubular screw con...

Drop-through rotary valve for powder and granular material feeding

Achieve precise control in discharging and feeding p...

Drop-through rotary valve for precise powder and granule feeding

Ensure precise material handling with this drop-through...

Blow-through rotary valves for pneumatic conveying

Optimize your pneumatic conveying systems with high-efficiency blow-th...

Rotary ball vibrators for fine powders and granular materials

Ideal for preventing material build-up and blockages, thes...

Rotary ball vibrators for aggregate reclaiming

Enhance efficiency in your production line with a solution that optimizes t...

Rotary ball vibrators for bulk solids discharging

Ideal for enhancing material flow, this equipment efficiently handles f...

Manual bag opener for bulk solids discharging

Effortlessly open and empty bags while containing dust emissions, ensuring a...

Combined hammer blaster for powder handling

Address powder flow issues with ease by preventing bridging and ratholing, ens...

Single impact pneumatic hammers for flow aids

Combat material clogs and ensure smooth flow in your production line with pn...

Pneumatic hammers for bulk solids discharging

Optimize your production efficiency and solve material flow challenges with ...

Pneumatic hammers for aiding material flow

Optimize material flow and eliminate blockages in your processing line with pne...

Industrial vibrator for high-frequency vibration

Achieve efficient material flow and compaction across various production ...

Rotary turbine vibrators for bulk solids discharging

Enhance the efficiency of material handling with high-speed, low-noi...

Rotary turbine vibrators for material flow aid

Optimize your production efficiency with high-speed, silent operation vibra...

Continuous impact vibrators for bulk material removal

Combat material flow issues like bridging and rat-holing with our i...

Rotary roller vibrators for concrete compacting and hopper emptying

Achieve higher compaction and efficient emptying wi...

Rotary roller vibrators for material flow assistance

Enhance material flow efficiency in your production line with high-f...

External electric motovibrators for industrial applications

Optimize material movement and improve discharge efficiency ...

External electric motovibrators for bulk solids conveying

Enhance material flow efficiency and solve challenging dischar...

Industrial electric vibrator for bulk solids discharging

Enhance material flow efficiency and ensure consistent output ac...

External electric motovibrators for hazardous materials

Ensure safety and efficiency in hazardous environments with relia...

Silo overfill protection system

Prevent silo overfilling and excess pressurization with a system designed to safeguard silos...

Silo overfilling safety system

Ensure safe silo filling with our system that prevents overfilling and excess pressurization,...

Lump breaking feeder valve for bulk material processing

Tackle bulk material flow challenges with a feeder valve engineer...

Micro-batch feeders for powder and granular material

Struggling with clog-prone powders? Gain precise control and consist...

Laboratory batch mixer for small scale production

Achieve rapid and reproducible mixing results with this laboratory batc...

Trough screw conveyor for flour mills

Optimize your flour processing with efficient material handling, precisely designed f...

Bin level indicator for bulk solids

Ensure precise material level detection across your production processes, minimizing th...

Bin level indicators for wastewater treatment

Ensure reliable material level monitoring in your silos and hoppers with ILT...

Bin level indicators for powder and granular material

Ensure precise inventory management and prevent overflows in your p...

Electronic pressure meter for silo safety

Ensure the safety of your silos by efficiently monitoring internal pressure chan...

Electronic pressure meters for silo safety monitoring

Ensure precise pressure management in your systems with this advanc...

Pneumatic linear vibrators for bulk material flow

Prevent bridging and rat-holing in your production process with silent,...

Cushioned pneumatic linear vibrators for bulk solids

Combat material bridging and rat-holing with silent vibratory techno...

Pipe couplings for pneumatic conveying lines

Ensure a secure and quick connection for your pneumatic lines with these pipe...

Hopper venting filter for efficient dust filtration

Achieve superior dust control and efficient material handling with a ...

Cushioned pneumatic vibrators for coarse particle materials compaction

Enhance your material flow and compaction proces...

Stainless steel trough screw conveyor

Ideal for precise handling of powdery and granular materials, this solution ensures m...

Waste bag compactor for bulk solids

Efficiently compact waste bags to a fraction of their volume, streamlining disposal whi...

Vibratory outlet hopper for bulk material discharge

Struggling with material bridging and inconsistent discharge? Enhance...

Food-grade bin activator for optimized material flow

Ensure hygienic and efficient discharge from hoppers with our food-g...

Food-grade bin activator for hygienic bulk solids discharge

Achieve consistent material flow and avoid contamination wit...

Industrial bin activator for smooth material flow

Enhance your material handling process with a solution that ensures con...

Rotary bin discharger for bulk solids

Efficiently manage bulk solids with a rotary bin discharger that minimizes residue an...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Bin activator for silo and hopper discharge

Ensure optimal material flow and prevent blockages in your storage systems wit...

Vibratory outlet hopper for bulk solids discharge

Reduce material handling challenges with highly efficient vibration tec...

Powder locks for safe bulk material handling

Ensure containment and prevent contamination while processing sensitive bulk ...

Powder handling vacuum conveyor system

Streamline your material transfer with a versatile vacuum conveyor system that ensur...

Bag rip-and-tip dump stations for bag emptying

Efficiently manage bag emptying operations with advanced dust containment a...

Big-bag unloading station for bulk materials

Facilitate seamless integration into your production line with efficient bulk...

Continuous vacuum conveyors for material flow control

Ensure consistent material transfer and reduce downtime in your pro...

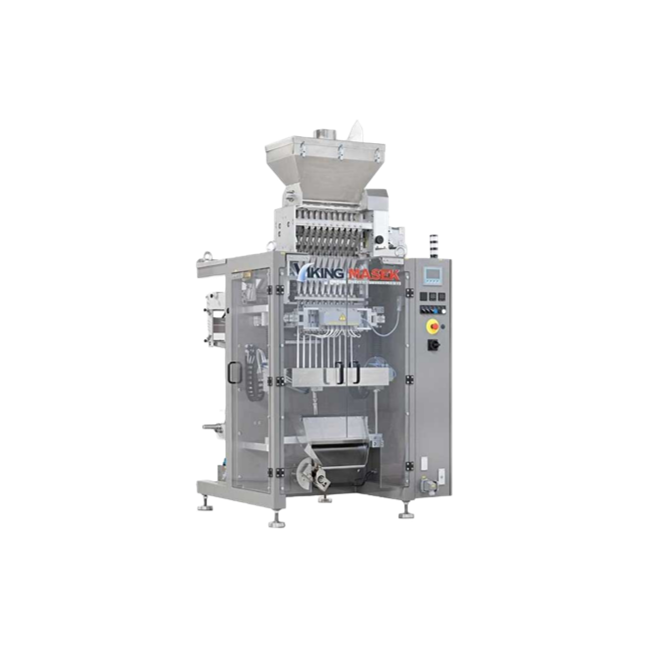

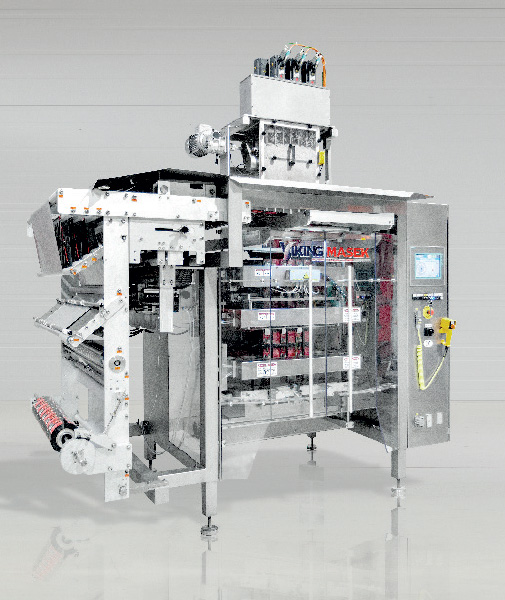

High-speed vertical form fill seal packaging machine

Optimize your packaging line with this high-speed vertical form fill...

Vertical form fill seal for large bag packaging

For operations requiring precise, large bag packaging, this equipment ensu...

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Pneumatic cyclone for effective product-air separation

Optimize particle separation with high-speed pneumatic cyclones, e...

Pneumatic diverting valve for powder and granule transfer

Efficiently redirect bulk materials from one point to another ...

Automatic packaging machine for open-mouth bags

Optimize your packaging line with precision weighing and high-speed baggin...

Industrial airlock for pneumatic systems

Ensure precise air and product separation in your pneumatic systems, maintaining m...

Quick change feeding devices for industrial applications

Experience seamless product transitions with quick-change feedin...

Multihead weighing system for dry free flowing products

Optimize your packaging line with precise weight measurements for...

Granule filling sachet machine

Ideal for optimizing packing operations, this granule-filling sachet machine ensures precise ...

multihead weigher for dry products

Optimize your production line with precise weighing for dry products, ensuring high-spee...

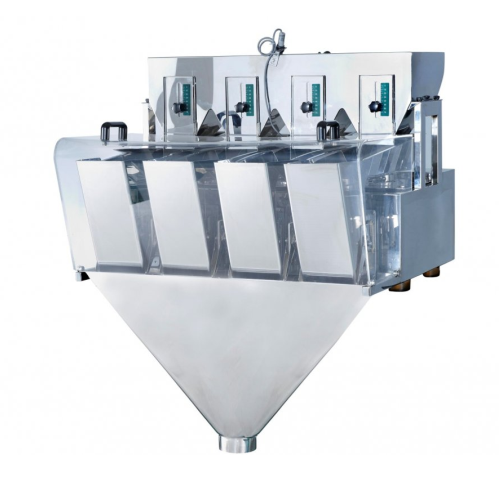

Linear weigher for dry free flowing products

Streamline your packaging process with precise weighing capabilities, ensurin...

Linear weigher for accurate food portioning

Ensure precise weight control for snacks and confectioneries with our advanced...

Linear weigher for dry free-flowing products

Optimize your packaging line with precise weighing for snacks, sweets, and gr...

Linear weigher for dry free flowing powder

Optimize your packaging line with precise weighing for free-flowing granular pr...

10 head multihead weigher for dry products

Optimize your weighing and packaging operations with precise and rapid handling...

14 head multihead weigher for dry products

Achieve precise and rapid weighing for a variety of dry, free-flowing products ...

Atex approved hammer mills for high-capacity particle size reduction

Ensure precise and reliable particle size reductio...

Bag tipping unit for Cip processes in powder handling

Ensure seamless powder handling and high hygiene standards in your ...

Batch dissolver for crystalline sugar and dextrose

Streamline your ingredient preparation with high-capacity batch dissol...

Autonomous ingredient dissolver for high-volume dry ingredient mixing

Efficiently mix multiple high volumes of dry ingr...

Continuous sugar dissolver for beverage production

Optimize your production line with a system that efficiently dissolves...

Batch dissolver for sugar or dextrose

Efficiently dissolve crystalline substances like sugar and dextrose with precision, e...

Continuous fluid bed dryer for powder and granules

Enhance your production line with precise moisture control and energy ...

Dry ingredient blending solution for confectionery and bakery products

Achieve seamless integration of dry inclusions i...

Automated ingredient weighing and dosing system

Streamline your production process with precise and consistent ingredient ...

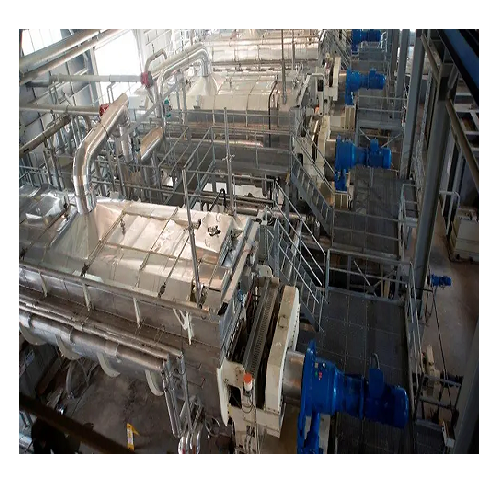

Industrial decanter centrifuge for solids separation

Optimize your production line with high-speed decanter centrifuges t...

Pneumatic inline sifter for dry flowing material

Ensure precise particle segregation and foreign matter removal with this ...

Sanitary separator for food processing applications

Ensure efficient separation and prevent contamination in food product...

High-capacity industrial sifter for chemical and food processing

Achieve unparalleled screening precision and efficiency...

Continuous mixer for accurate ingredient blending

Achieve precise mixing in continuous production with optimal control ov...

High-force texture analyser for precise measurement

Achieve unparalleled precision in texture analysis for high-force app...

Laser-based volume measurement for bakery and solid products

For precision in product quality control, this laser-based ...

Powder flow measurement system

Achieve precise control over powder consistency and prevent process disruptions by assessing ...

Line blender for continuous flow mixing

Achieve instantaneous mixing with minimal space and maintenance using a continuous ...

Rising/falling film plate evaporator for heat sensitive products

Efficiently concentrate heat-sensitive liquids with ris...

Falling film plate evaporators for fruit juice concentration

Achieve precise concentration of liquid products with minim...

Twin screw feeder with stirring agitator for poor flowing powders

Optimize your processing line with a highly adaptable...

Feeder controller for gravimetric feeders

Optimize your dosing precision and monitoring accuracy with a versatile feeder c...

Granulate screening technology for precise particle size separation

Achieve exceptional sorting precision and maintain ...

Metal detection system for powders & granules

Ensure product integrity and protect your machinery from metallic contaminan...

Metal detector systems for conveyor belts and chutes

Ensure the integrity of your production line by efficiently detectin...

Shredder for fine particle size reduction

Optimize your production line with high-speed shredding technology designed for ...

Industrial high-speed turbo blender

Achieve homogeneous blending with high-speed precision, ideal for creating fine product...

High-speed container loading system for granulated bulk materials

Optimize your loading operations with a robust system...

Bulk reception solution for industrial material handling

Optimize your operations with an above-ground bulk reception sys...

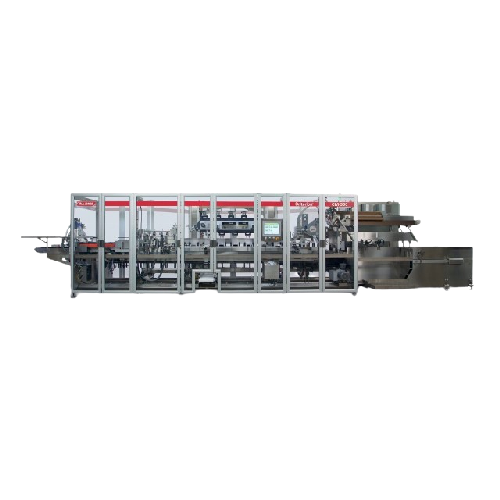

High-speed Cartoner For Single-Serve Products

Large-volume producers of single-serve packs, such as sugar sticks, instant ...

Sugar dissolving system for beverages

In the beverage industry, production of sweet drinks requires the addition of sugar s...

Mini sugar coating machine

The coating of grains or nuts with sugar is a popular process in the manufacture of many bakery p...

Inline syrup room

The beverage industry requires high-quality syrup. Soft drinks, fruit juices, still drinks, ice tea, flat o...

Pillow bag vertical packing machine

When packaging products such as seeds, cereal, snacks, candies, nuts, tea, dried fruits...

Metal detector for granulated products

Free-fall applications, such us flour, sugar, spices and other granulated or powdere...

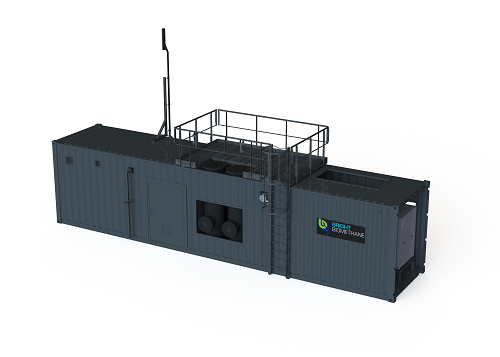

ATEX Indoor silo for sugar and flour

Storing granulated or powdered materials such as sugar and flour prior to processing r...

Grinder for spices and coffee

Gentle grinding of coffee down to all grades from coarse to fine requires high precision proce...

Modular HFFS Machine

A large range of sizes and types is available, with traditional horizontal form fill and seal machines b...

Small sugar mill for entry level production

Sugar powder is a key ingredient in a wide range of bakery, confectionery, and...

Continuous vertical cartoner

When producing cereals, it is paramount to stay on top of market trends. New packaging forms ca...

Stickpack Machine

If you are looking to pack your product into stick packs from 17 x 40 mm to 100 x 200 mm in size, you may b...

Granola batch mixer

The production of granola-based recipes requires careful ingredients handling to ensure optimum quality. ...

Sachet Machine

If you want to pack into eye-catching 4-side sealed sachets between 40×50 mm and 250×200 mm in size, ...

Bagger for open mouth bags

Where a stand-alone bagger is required for filling large, open mouth bags, a delivery method is n...

Automatic bagging machine for open mouth bags

Open mouth bags allow for a variety of different products to be packaged, wi...

Palletizing robot arm

For high speed palletizing, palletizing high payloads, or just where greater flexibility is required, i...

Open-mouth baggers for free flowing powders

For bagging free flowing materials into open mouth bags, this system is ideal....

Continuous cooker for hard caramels

Continuously cook ingredients for your hard caramel-based product. This is a three-stag...

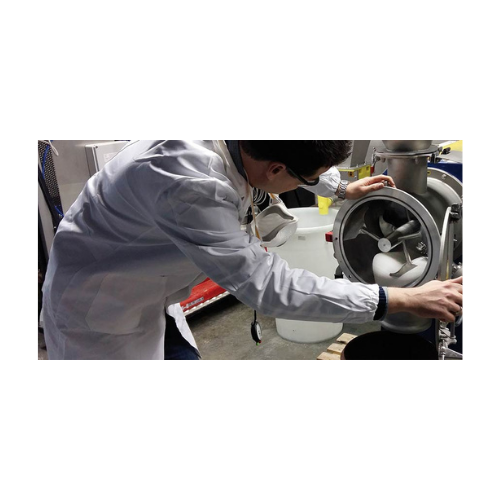

Isolator centrifuge

For transferring highly active pharmaceutical ingredients (HAPI) without contamination from the isolator ...