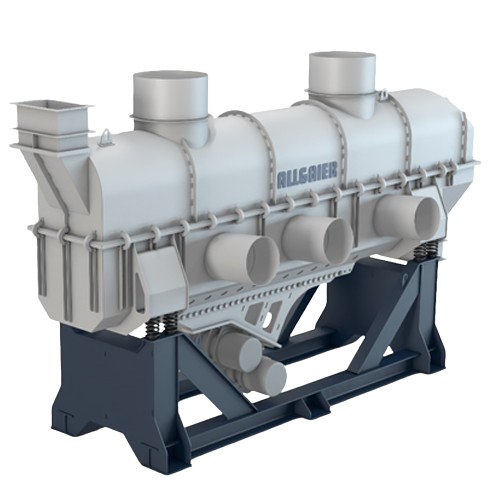

Fluidized bed dryer for industrial materials

Enhance product quality and energy efficiency with fluidized bed dryers, optimizing drying and cooling to meet precise moisture levels while maintaining uniformity across varied materials.

Dries and Cools Bulk Materials Efficiently

The Fluidized Bed Dryer/Cooler from Allgaier Process Technology is designed to address moisture control challenges in bulk material processing. This equipment dries and cools a range of products like plastic granules, pharmaceutical tablets, and industrial salts through a fluidization process using hot gas streams. It operates continuously or in batches, making it versatile for various industrial needs, including mining, chemicals, and food processing.

With options for static or vibratory fluidization, the system exhibits exceptional heat recovery and energy efficiency, cutting energy costs by harnessing waste heat. It effectively handles materials with varied moisture levels, preventing issues like cratering and nesting, thanks to its vibratory support.

The Dryer/Cooler is highly customizable, supporting integration into existing production lines with capacities tailored to your throughput requirements. Available in corrosion-resistant materials, it’s designed for easy cleaning and minimal maintenance, ensuring long-term operation without compromising product quality.

Benefits

- Enhances product quality by ensuring uniform drying and cooling of diverse bulk materials.

- Lowers energy costs through efficient heat recovery and optimized thermal processes.

- Increases operational flexibility with continuous or batch processing modes.

- Reduces maintenance with robust construction and easy-clean design.

- Adapts to specific industry needs with customizable material and configuration options.

- Applications

- Foam granules, Plastic granules, Crystalline products, Foodstuffs, Chemicals, Wood and particle boards, Metallurgy, Urea, Granulates, Mining, Waste and recycling, Cocoa, Ceramics, Animal feed, Sugar, Plastics, Biofuels and pellets, Pharmaceuticals, Fodder, Powders, Stones and soil, Salts

- End products

- Eps beads, Recycled aggregates, Steel powder, Mined minerals, Confectionery sugar, Cocoa powder, Pharmaceutical tablets, Polyethylene beads, Fish meal, Mdf fibers, Talcum powder, Livestock pellets, Porcelain tiles, Quarry dust, Aromatics, Chemical granulates, Food starch, Pet pellets, Urea fertilizer, Industrial salts, Biodiesel pellets, Borax crystals

- Steps before

- Grinding, Purification, Emulsification

- Steps after

- Screening, Storage, Bagging, Packing, Coating

- Input ingredients

- bulk materials, granulates, powders, granular materials, flowable materials, wet product, crystalline products, animal feed, sugar, urea, cocoa, salts

- Output ingredients

- dried product, cooled product, expanded foam granules, heated urea, dried/cooked cocoa, dried salts

- Market info

- Allgaier Process Technology is known for manufacturing advanced screening, drying, cooling, and sorting equipment for various industries, specializing in custom-engineered solutions and innovative designs to enhance efficiency and productivity.

- Drying Zones

- Multiple zones for efficient drying

- Cooling Zones

- Integrated cooling zones

- Heating Method

- Gas/oil burner, electric heating coil

- Drying Temperature

- Up to 600°C

- Fluid Bed Height

- Large fluid bed heights

- Air Velocity

- Fast air velocities

- Vibration System

- Free-swinging or two-mass oscillator

- Energy Efficiency

- Optimized heat recovery systems

- Heating Media

- Inert gas, air

- Moisture Levels

- Accommodates high moisture levels

- Automation

- PLC-controlled systems

- Product Size Compatibility

- Variety of particle sizes

- System Design

- Compact design available

- Waste Heat Utilization

- Includes waste heat recovery

- Dryer Type

- Static or Vibratory

- Working mechanism

- Static / Vibratory fluidized bed

- Integrated steps

- Drying and Cooling

- Batch vs continuous operation

- Batch / Continuous

- Automation level

- Manual / PLC

- Cleaning method

- CIP / Manual

- Energy efficiency

- High due to heat recovery

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Lumping prevention

- Vibration support

- Compact design

- Yes

- Machine footprint

- Compact

- Discharge method

- Product outlet

- Fluid bed height

- Large

- Equipment type

- Static/Vibratory

- Drive mechanism

- Free-swinging/two-mass oscillator

- Heating type

- Gas/oil burner, electric coil, heat exchanger

- Drive mechanism type

- Free-swinging / Two-mass oscillator

- Vibration support

- Elastic connecting pieces / Decoupled vibration

- Heating method

- Direct gas/oil burner / Electric heating coil / Indirect via heat exchangers

- Heat recovery integration

- Built-in heating surfaces / High-temperature heat pumps

- Fluid bed type

- Static / Vibratory

- Cooling integration

- Combined drying and cooling

- Automation integration

- PLC / Batch or inline operation

- Heat utilization

- Waste heat utilization

- Energy efficiency measures

- Heat recovery systems / Eco-solutions