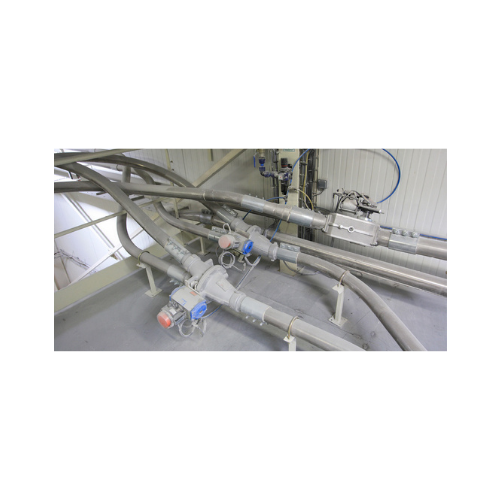

Flap diverter valves for pneumatic conveying

Streamline material flow in your pneumatic conveying system by effortlessly redirecting powders, pellets, or granules, ensuring minimal pressure drop and high sealing efficiency in your production process.

Diverts and Routes Powders, Pellets, and Granules

The VAB Flap Diverter Valve from WAMGROUP is designed for effective rerouting in pneumatic conveying systems, diverting powders, pellets, and granules with precision. Its swinging flap mechanism ensures smooth transitions, minimizing pressure drop and maximizing sealing efficiency. Applications span various industries, from food processing with products like jasmine rice and chocolate chip cookies to plastics manufacturing handling nylon plastic and silicone rubber. Operating in continuous, automated environments, the valve accommodates diameters from 50 to 200 mm and withstands pressures up to 2.0 bar. Its robust construction includes an EPDM food-grade seal and options for cast aluminum or nickel-plated finishes, ensuring durability and compliance. Integration into existing systems is seamless, with ATEX-certified versions available for safety in explosive atmospheres. Maintenance is simplified with a modular design and limited components, promoting extended operational uptime.

Benefits

- Ensures efficient material flow with minimal pressure loss, reducing energy costs.

- Enhances operational flexibility by seamlessly integrating into pneumatic systems.

- Promotes maintenance efficiency with modular, easily accessible design.

- Supports a wide range of applications with adaptable configurations and sizes.

- Maintains high safety standards with available ATEX certification for explosive environments.

- Applications

- Lime, Pellets, Granules, Biscuit processing, Cosmetics, Soap, Pesticides, Minerals, Chocolate, Bakery products, Fly-ash, Cement, Insecticides, Detergents, Glass, Noodle making, Spices, Rubber, Resin, Cocoa, Animal feed, Pasta, Sugar, Convenience food, Varnish, Rice, Plastics, Salt, Fertilizers, Petfood, Pharmaceuticals, Beverages, Fish food, Paint, Coffee, Gypsum, Powders, Refractory products

- End products

- Spaghetti, Brown sugar, Nylon plastic, Silicone rubber, Gypsum powder, Refractory bricks, Hydrated lime, Protein powder, Espresso beans, Cocoa nibs, Rubber granules, Jasmine rice, Recycled pet pellets, Chicken feed, Chocolate chip cookies, Epoxy resin, Fiberglass, Portland cement, Fish meal, Plastic pellets, Lip balm, Ammonium nitrate fertilizer, Soda, Milk chocolate, Sourdough bread, Liquid laundry detergent, Ramen noodles, Acrylic paint, Energy drink, High-density polyethylene, Polyurethane varnish, Lavender soap, Instant ramen seasoning, Table salt, Glyphosate pesticide, Mosquito coil, Instant coffee granules, Silica sand, Dry cat food, Aspirin tablets

- Steps before

- Bulk Solids Conveying, Material Flow Interception, Powders Re-routing, Pellets Re-routing, Granules Re-routing

- Steps after

- Bulk Solids Conveying, Production Line Processing

- Input ingredients

- powders, pellets, granules

- Output ingredients

- powders, pellets, granules

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Material type

- Powders, pellets, granules

- Actuator type

- Various actuators in different voltages

- Material casing

- Cast aluminium alloy

- Seal material

- EPDM (food-grade certified, antistatic)

- Metal plate

- 304 stainless steel

- Working temperature range

- -20 ~ 80 °C (-4 ~ 176 °F)

- Working pressure

- max. 2.0 bar, min. -0.3 bar (29 / -4.3 PSI)

- Diameter

- 50 ~ 200 mm (2 ~ 8 in)

- Diverting angle

- 22.5°

- Pressure drop

- Minimum

- Design

- Modular

- Overall dimensions

- Lightweight and compact

- Smoothness

- Smooth internal surface (no dead spots)

- Transition effect

- Minimum

- Flange types

- TOREX or DIN

- Working mechanism

- Flap diversion

- Flow rerouting

- Powders, pellets, granules

- Operation type

- Pneumatic conveying

- Pressure drop

- Minimum

- High sealing efficiency

- Yes

- Changeover flexibility

- Two-way diverter

- Maintenance

- Easy, modular design

- Automation level

- Manual / Actuator-driven

- Temperature range

- -20 to 80 °C (-4 to 176 °F)

- Pressure range

- -0.3 to 2.0 bar (-4.3 to 29 PSI)

- Biological compatibility

- Food-grade certified

- Cleanability

- Easy maintenance

- Density/particle size

- Powders, pellets, granules

- Food-Grade Certification

- EPDM (white colour, antistatic)

- Diameter

- 50 ~ 200 mm (2 ~ 8 in)

- Compact Design

- Lightweight and compact overall dimensions

- Smooth Internal Surface

- No dead spots

- Narrow Diverting Angle

- 22.5°

- Modular Design

- Easy maintenance thanks to limited number of components

- Material Construction

- Cast aluminum alloy casing