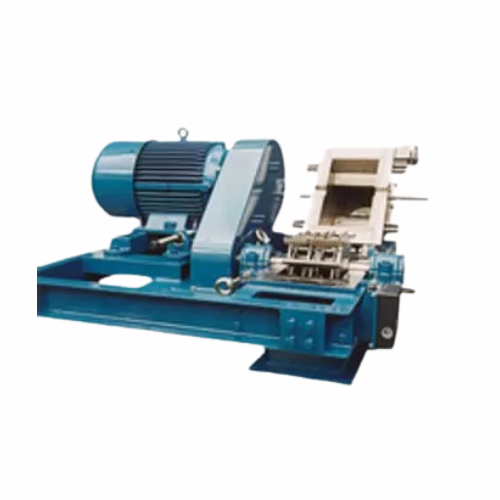

High-speed pulverizer for carbon black production

Achieve consistent particle size and optimal homogenization with high-speed grinding, mixing, and impact drying—ideal for enhancing the quality and precision of your production line across various stages.

Processes Powders and Particles Efficiently

The Pulverizer MP from Hosokawa Alpine is a high-speed hammer mill designed for the continuous processing of powders and particles across various industries, including cosmetics, pharmaceuticals, and food processing. This robust equipment excels in grinding, mixing, and homogenization, leveraging impact drying, cryogenic, and inert gas methods for optimal results. It produces end-products such as paracetamol tablets, pigment pastes, and cosmetic powders with remarkable precision and efficiency.

Engineered for versatility, the Pulverizer MP accommodates materials ranging from soft resins to uranium oxide, ensuring a consistent particle size distribution critical for downstream processes. It integrates seamlessly into existing production lines, offering PLC control for enhanced automation and remote monitoring. Enhanced by a design that utilizes up to 20% less energy through optimized motor speeds, this unit provides considerable savings in operational costs.

Constructed from corrosion-resistant materials like stainless steel, the Pulverizer MP can be tailored to meet specific industry requirements. Its compliance with GMP standards makes it a top choice for sensitive applications, while its easy-to-clean design reduces maintenance downtime. With customizable feed systems and support for up to three metering screws, this machine offers flexibility and precision in material handling that meets the rigorous demands of today’s industrial environments.

Benefits

- Enhances productivity through continuous high-speed operation.

- Reduces operational costs with energy-efficient motor optimization.

- Ensures consistent product quality with precise particle sizing.

- Minimizes maintenance downtime with easy-to-clean design.

- Complies with GMP standards, ensuring safety and regulatory compliance.

- Applications

- Chemicals, Dyes, Tobacco, Cosmetics, Foodstuffs, Particle processing products, Drinks, Plastics, Resins, Powder, Carbon black, Uranium oxide, Pharmaceuticals

- End products

- Pigment pastes, Toner for printers, Face creams, Cocoa powder, Cosmetic powders, Chewing tobacco, Polyethylene film, Dry flue gas cleaning agents, Pesticide formulations, Nuclear fuel pellets, Melamine formaldehyde resins, Paracetamol tablets, Instant coffee

- Steps before

- Drying, Purification, Pre-crushing, Feeding and metering

- Steps after

- Packing, Coating, Homogenization, Particle analysis

- Input ingredients

- carbon black, paracetamol, cocoa, sugar, dyes, plant protectors, melamine resin, uranium oxide

- Output ingredients

- ground carbon black, ground paracetamol, ground cocoa, ground sugar, ground dyes, ground plant protectors, ground melamine resin, ground uranium oxide

- Market info

- Hosokawa Alpine is known for its expertise in manufacturing advanced process equipment and systems for powder and particle processing technology. It has a strong reputation for innovation, quality engineering, and customer-focused solutions in various industries.

- Speed

- Up to 100m/s

- Material Feed

- Single hole, twin hole, triple hole metering screws

- Feed Type

- Gravity feed

- Specific Design

- Special Carbon Black design with suction inlet

- Functionality

- Grinding, mixing, and homogenisation

- Working mechanism

- High-speed hammer mills

- Process steps

- Grinding, mixing and homogenisation

- Batch vs. continuous operation

- Continuous operation

- Cleaning method

- Easy to clean

- Automation level

- Manual / PLC control

- Abrasion resistance

- Suitable for soft to medium-hard materials

- Biological compatibility

- Pharmaceutical products

- Cleanability

- Easy to clean and maintain

- Corrosive resistance (e.g. acids)

- Constructed with wear protection options

- Density/particle size

- Grinding capabilities for various particle sizes

- Chemical compatibility

- Chemicals and plastics processing

- Footprint

- Compact design

- Feed method

- Metering screws / Gravity feed

- Discharge method

- Suction inlet / Injector

- Construction material

- Customized based on application

- Shape and size

- Varies by model (e.g. Pulverizer SH / DHorTH)

- Construction material

- Various options based on application

- Wear protection

- Customizable based on model

- Feed metering element

- Single, twin, or triple hole metering screws

- Feed type

- Gravity feed or metered feed

- Special designs

- Option for special carbon black design