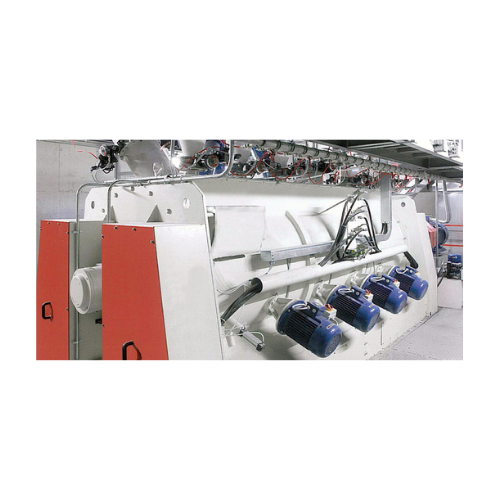

Batch-type single shaft mixers with bomb-bay discharge

When you need rapid, residue-free discharge in your batch mixing processes, these mixers provide efficient homogenizing, minimizing material waste and ensuring high-quality output across diverse production needs.

Mixes and Discharges with Minimal Residue

The WBHP and WBHT Batch-Type Single Shaft Mixers from the WAMGROUP offer high-efficiency mixing solutions designed for industries such as construction, food processing, and chemicals. These mixers are equipped with a bomb-bay discharge system that ensures rapid, almost residue-free emptying with precision. With capacities ranging from 165 to 20,000 liters, they accommodate a wide variety of production needs. Their robust construction features optional materials like anti-wear and stainless steel, catering to durability and corrosion resistance. Designed for both solid and liquid applications, they support high-speed batch operations, enhancing productivity in diverse applications from concrete and pasta to fertilizers and detergents. The mixers integrate seamlessly into automated lines, with features such as variable mixing tools and optional high-speed choppers for increased flexibility. They excel in energy efficiency and offer easy cleaning access, supported by various sealing options to ensure durability and minimize maintenance downtime. Customization options, including temperature control and anti-wear coatings, are available to meet specific production requirements.

Benefits

- Maximizes productivity with rapid discharge and minimal residue.

- Ensures consistent batch quality with high mixing homogeneity.

- Reduces maintenance needs through durable construction and accessible cleaning.

- Adapts to diverse material requirements with customizable mixing tools.

- Integrates seamlessly into automated systems, enhancing operational efficiency.

- Applications

- Biscuit processing, Cosmetics, Pesticides, Beverage processing, Insecticides, Detergents, Spices, Varnishes, Cocoa and chocolate, Animal feed, Sugar, Building materials, Pet food, Food processing, Soaps, Resins, Baby food, Salt, Paints, Fertilizers, Bakeries, Coffee, Pasta and noodles

- End products

- Wood varnish, Pasta dough, Chicken feed, Table salt, Herbicide mixtures, Baby formula, Npk fertilizer granules, Concrete mix, Bar soap, Epoxy resin, Curry powder blend, Acrylic paint, Espresso blend, Chocolate coating, Body lotion

- Steps before

- Grinding, DryMix Building Materials Processing, Chemical Ad-Mixtures Preparation, Rice Milling, Sugar Processing

- Steps after

- Packing, Product Inspection, Sterilization, Heating/Cooling, Liquid Injection

- Input ingredients

- Output ingredients

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Capacity

- 165 ~ 20, 000 litres per batch

- Mixing ratio

- 1/100, 000

- Variation coefficient (CV)

- between 3 and 5

- Liquid addition

- Up to 20%

- Mixing time

- 1 ~ 4 min

- Material residue

- Less than 0.1%

- Shaft seals

- Air/nitrogen-purged or grease sealing

- Material

- Carbon steel, anti-wear steel, 304L/316L stainless steel

- Surface finishing

- Grit silking, mirror polishing, glass bead blasting

- Mixing tools

- Boxed/toothed ploughshare, blade, toothed blade-type

- Power rating

- Adapted to application

- Discharge method

- Bomb-bay discharge

- Discharge method

- Bomb-bay discharge

- Discharge time

- Shortest possible time

- Mixing type

- Batch

- Residue level

- Less than 0.1%

- Door type

- Dust-tight bomb-bay door

- Opening angle

- 15° (WBHP), 60° (WBHT)

- Liquid addition

- Up to 20%

- Mixing time

- 1 ~ 4 min

- Automation level

- Possibility of PLC integration

- Maintenance level

- Low

- Cleaning method

- Easy access, manual

- Homogeneity

- Maximum

- Abrasion resistance

- High

- Biological compatibility

- Suitable for food and animal feed

- Cleanability

- Easy to clean with minimal residue

- Corrosive resistance

- If needed, stainless steel option available

- Density/particle size adaptability

- Suitable for various densities and particle sizes

- Liquid addition

- Up to 20%

- Discharge method

- Bomb-bay door

- Mixing chamber material

- Carbon steel / Anti-wear steel / 304L / 316L stainless steel

- Surface finishing

- Grit silking, mirror polishing, glass bead blasting

- Mixing tools

- Boxed ploughshare, toothed ploughshare, blade, toothed blade-type

- End bearing assemblies

- Air or nitrogen-purged shaft seals or grease sealing

- Discharge method

- Bomb-Bay Discharge

- Control panel type

- Pneumatic control panel

- Surface finishing

- Grit silking, mirror polishing, glass bead blasting

- Mixing tools coating

- Anti-wear coating

- Mixing chamber material

- Carbon steel, anti-wear steel, 304L / 316L stainless steel

- Seal type

- Air or nitrogen-purged shaft seals, grease sealing

- Special surface treatment

- Anti-wear liner, replaceable tile coating, ceramic liner, Teflon liner, stainless steel mesh

- Liquid addition capability

- Up to 20%

- Chopper speed

- High-speed choppers

- Temperature control

- Heating / cooling jacketed chamber, PT 100 temperature probe