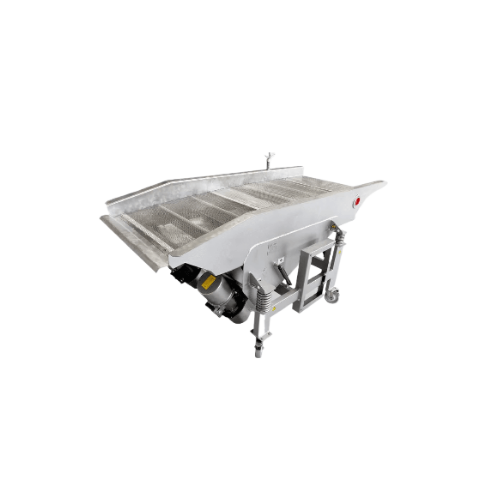

Food product sifter

Ensure precise separation with vibratory sifters designed for continuous operation, delivering gentle handling and efficient removal of unwanted particles from solid and granular food products, all while minimizing power consumption and maintenance.

Efficiently Screens and Separates Diverse Materials

The GEA Scan-Vibro Sifters are engineered to offer robust and reliable screening solutions across the food, beverage, dairy, and pharmaceutical sectors. With their hygienically designed vibrating sifting mechanism, these sifters ensure gentle product handling, crucial for maintaining the quality of sensitive goods like freeze-dried coffee or mozzarella cheese cubes. Capable of operating 24/7, they integrate seamlessly into production lines, handling vast applications from separating cereals to grading fish meal.

These sifters provide flexibility with one or more screen decks, supporting processing capacities that accommodate varied product throughput needs. The equipment design includes a simple tool-free screen replacement system, facilitating quick transition between batch operations and reducing downtime. Opt for cleaning-in-place (CIP) options to simplify maintenance in strict hygiene environments.

The energy-efficient, lubrication-free motors reduce operating costs and are available in stainless steel, enhancing durability and ensuring low service intervals. Compliance with stringent standards like USDA 3-A and EHEDG further ensures suitability for food-grade operations while offering options to tailor configurations for specific industrial needs.

Benefits

- Enhances product integrity with gentle material handling, minimizing damage and waste.

- Lowers operational costs through energy-efficient motors and reduced maintenance requirements.

- Maintains continuous production with 24/7 operational capability and easy screen replacements.

- Ensures compliance with food safety standards, such as USDA 3-A and EHEDG.

- Facilitates quick cleaning and transition between processes with CIP compatibility.

- Applications

- Wood pellets, Cheese, Fish flour, Seeds, Minerals, Dairy, Fish, Cement, Convenience foods, Household waste, Freeze-dried coffee, Animal feed, Sugar, Pet food, Freeze-dried products, Frozen vegetables, Fertilizer, Food ingredients, Salt, Recycling, Tea leaves, Meat, Cereals, Vegetables, Poultry, Brewers' yeast

- End products

- Concrete mix, Plastic granules, Vegetable mixes, Sunflower seeds, Frozen green peas, Chicken nuggets, Soups, Spice blends, Frozen carrots, Kibble, Pine pellets, Fish fillets, Fish meal, Recycled paper, Packaged tea bags, Cornflakes, Ale yeast, Granulated sugar, Freeze-dried instant coffee, Ground beef, Milk powder, Compost, Granola, Ready-to-eat meals, Fish bone meal, Muesli base flakes, Table salt, Freeze-dried strawberries, Mozzarella cheese cubes, Silica sand, Roast and ground coffee, Nitrogen fertilizer

- Steps before

- Grinding, Blending, Mixing, Pre-cooking, Pre-processing

- Steps after

- Packaging, Sterilization, Assembly, Heat treatment, Quality inspection

- Input ingredients

- cereals, frozen vegetables, freeze-dried products, cheese, convenience foods, food ingredients, fish, vegetables, poultry, meat, salt, sugar, brewers’ yeast, freeze-dried coffee, tea leaves, wood pellets, seeds, minerals, cement, fish flour, fertilizer, household waste

- Output ingredients

- separated particles, graded coffee, removed tea leaves, dust-free materials, lump-free substances, unwanted particles removed

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Operation temperature

- -20 to +55 °C

- Screening area

- 0.5–8.0 m²

- Power consumption

- Low

- Sifting efficiency

- High

- Screen decks

- One, two or more

- Oscillation,vibration

- Special combination with adjustable stroke length

- Screen cleaning system

- Available to prevent blinding

- Operation mode

- Continuous

- Cleaning method

- CIP-compatible

- Automation level

- Tool-free screen replacement

- Gentle product handling

- Oscillation and vibration

- Temperature range

- –20 to +55 °C

- Screen cleaning system

- Prevent blinding

- Power consumption

- Low

- Maintenance interval

- Long interval

- Mobility

- Support frame mounted on wheels

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact design

- Sifting area

- 0.5–8.0 m²

- Screen decks

- One or more

- Screen size

- Customizable

- Screen tensioning

- Manual or pneumatic

- Mobility option

- Wheeled support frame

- Material

- Stainless steel

- Top covers

- Gas struts, various inspection covers

- Operating temperature

- –20 to +55 °C

- Screen size

- 0.5–8.0 m²

- Screen decks

- One, two or more

- Metal detectable screen mesh

- EN 1.4016/AISI 430

- Mobility

- Support frame mounted on wheels

- Screen tensioning system

- Manual or pneumatic

- Finish grades

- Polished from 1.3–0.2 µm

- Top covers

- Fitted with gas struts and various inspection covers