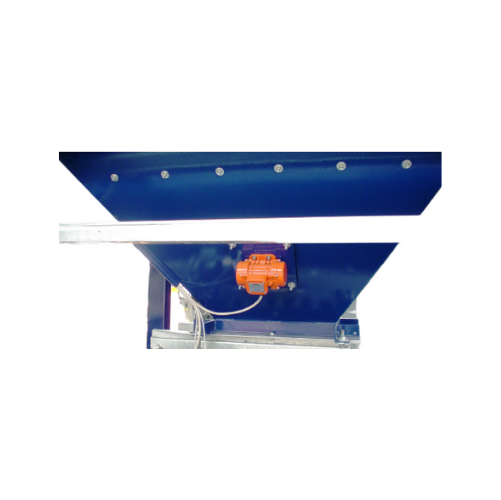

External electric motovibrators for industrial applications

Optimize material movement and improve discharge efficiency across diverse processes with this industrial vibrator technology, designed to handle challenging conditions in vibrating, conveying, and screening applications.

Enhances Material Flow and Compacting in Production Lines

The External Electric Motovibrators MVE from WAMGROUP are tailored for industries requiring optimized material handling and flow efficiency. These motovibrators utilize a robust FMEA-designed electric motor with eccentric weights, creating precise vibrations for material discharge and compacting processes. Suitable for applications across construction, food processing, and chemical manufacturing, they handle diverse end-products from precast concrete panels to pharmaceutical tablets. Offering centrifugal forces between 20 to 26,000 kg, they ensure adaptable performance in vibrating, conveying, and screening. Available with ATEX ExII3D and ETL, Class II, Division 2 certification, these motovibrators are ideal for hazardous environments, with variable voltages to match global electric standards. Maintenance is simplified with vacuum-impregnated windings and premium bearings, while customization options include PTC thermistors and stainless steel covers.

Benefits

- Ensures optimal material handling with a wide range of centrifugal forces.

- Enhances operational safety in hazardous environments with ATEX and ETL certifications.

- Minimizes energy consumption through multiple voltage compatibility.

- Reduces maintenance costs with durable design and quality materials.

- Offers flexible application integration, improving production line efficiency.

- Applications

- Lime, Brick production, Sugar processing, Gas, Asphalt, Rubber processing, Biogas, Biscuit processing, Fruit processing, Pesticides, Minerals, Sand blasting, Cement, Dust filtration, Detergents, Glass, Noodle making, Spices, Varnishes, Lime dosing, Biomass, Grain storage, Precast concrete, Coffee processing, Ceramics, Animal feed, Pasta, Building materials, Convenience food, Meat processing, Oil, Fertilizer, Fish processing, Solid waste handling, Cocoa processing, Plastics, Baby food, Paints, Pharmaceuticals, Waste water treatment, Fish food, Salt processing, Gypsum, Breweries

- End products

- Biscuits, Pelleted animal feed, Nitrogen fertilizers, Wood pellets, Sandblasted surfaces, Noodles, Hydrated lime, Compostable solid waste, Acrylic paints, Processed meats, Beer, Cement blocks, Crude oil, Cocoa butter, Biogas digestates, Pharmaceutical tablets, Ceramic tiles, Powdered spices, Glass sheets, Iodized salt, Extruded fish food, Fish fillets, Pasta sheets, Automotive rubber parts, Gypsum board, Ready-to-eat convenience meals, Synthetic pesticides, Liquid detergents, Refined sugar, Grain silos, Clay bricks, Ground coffee, Baby formula, Mineral powders, Canned fruits, Natural gas, Hydrated lime solutions, Dust-free environments, Plastic components, Precast concrete panels, Treated wastewater, Asphalt mixtures, Emulsion varnishes

- Steps before

- Material Mixing, Material Crushing, Grinding, Screening

- Steps after

- Material Discharge, Packing, Conveying, Compacting

- Input ingredients

- vibrating equipment, hoppers, silos, construction materials, feed and food materials, chemical ad-mixtures, ceramics, concrete, plastic and rubber materials, fertilizers, pharmaceuticals, minerals, biomass, wood, environmental waste materials

- Output ingredients

- centrifugal force, material discharge, conveyed materials, screened materials, sized materials, compacted materials, construction products, processed feed and food, chemical products, ceramic products, concrete products, recycled plastic and rubber, processed fertilizers, pharmaceutical products, mineral products, bio-energy, processed wood, treated waste

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Centrifugal force

- 20 ~ 26, 000 kg

- Poles

- 2, 4, 6, 8 poles

- Motor type

- Single phase, Three-phase, DC

- Insulation class

- Class F

- Certification

- ATEX ExII3D, ETL Class II, Division 2

- Material discharge improvement

- Flow aids

- Movement type

- Circular/Linear

- Bearings quality

- Premium

- Casing design

- FMEA-designed

- Working Mechanism

- Sinusoidal centrifugal force

- Automation level

- Manual / PLC-controlled

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual

- Energy efficiency

- Depends on motor type and usage

- Changeover time

- Minimal

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- ATEX certification

- ExII3D

- ETL certification

- Class II, Division 2

- Motor phase

- Single phase, Three-phase, DC

- Footprint

- Compact

- Casing

- Sturdy FMEA-designed cast casing

- Material covers

- Stainless steel (on request)

- Mass adjustment

- Split covers for quick adjustment (on request)

- Bearings quality

- Premium quality bearings

- Vacuum impregnation

- Windings are vacuum impregnated

- Casing design

- FMEA-designed cast casing