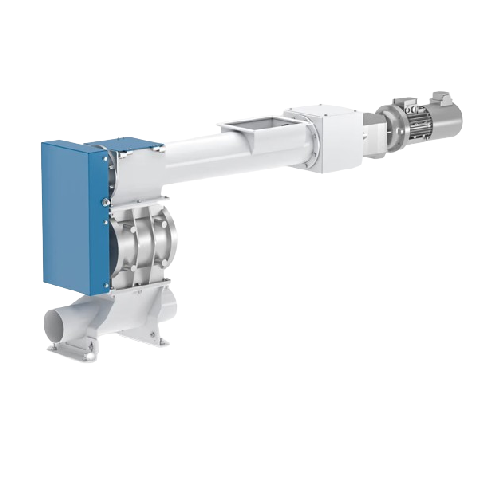

Continuous raw material distribution screw doser

Optimize your material flow with a screw doser designed for precise and continuous distribution, ensuring consistent quality and smooth operation in complex production lines.

Distributes and Conveys Raw Materials Consistently

The Screw Doser from GEA offers a reliable solution for continuous raw material dosing and conveying, ideal for industries ranging from food and pharmaceuticals to chemicals and energy. Featuring a tubular body with an internal screw, it uses a gearmotor driven by an inverter for variable pitch and rotation control. This system ensures equitable material distribution to subsequent processing phases via a pneumatic conveyor with a rotary valve. Noteworthy is its construction, available with food-safe paint and stainless-steel options for optimal hygiene and corrosion resistance. The equipment supports automated operations, maintaining process integrity through advanced clogging prevention measures. Its design accommodates uneven installation sites, ensuring flexibility and integration within existing production lines. For those seeking compliance, it meets stringent hygiene and safety standards, making it suitable for sensitive applications. The Screw Doser also provides customization options and engineering support, tailoring configurations to specific production needs.

Benefits

- Ensures consistent product quality by providing precise dosing of powders and granules.

- Enhances operational flexibility with variable pitch adjustments.

- Reduces downtime with a clogging prevention mechanism.

- Maintains high hygiene standards, minimizing contamination risk.

- Adapts to challenging installation sites with its inclined design option.

- Applications

- Food, Personal care, New food products, Marine, Raw materials, Gas, Energy, Beverage, Oil, Environmental products, Chemical, Home, Dairy, Pharmaceuticals

- End products

- Detergent powders, Cosmetic creams, Coffee blends, Protein powders, Air purification agents, Pharmaceutical tablets, Beverage flavoring agents, Biodiesel components, Chemical compounds, Processed cheese mix, Crude oil additives, Shampoo bases, Plant-based meat products, Lactose powder, Sugar granules, Marine fuel additives

- Steps before

- Purification, Drying, Grinding

- Steps after

- Packing, Tablet Pressing

- Input ingredients

- raw materials, bulk materials

- Output ingredients

- processed materials, distributed materials through pneumatic conveyor

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Feed rate

- Continuously and constantly

- Body Type

- Tubular

- Internal Component

- Variable pitch screw

- Screw Rotation

- Driven by gearmotor controlled by inverter

- Clogging Prevention

- Equipped with device

- Version

- Inclined for uneven sites

- Construction Material

- Stainless steel (optional)

- Surface Treatment

- Food safe paint

- Hygiene Standard

- Highest

- Safety Systems

- Accident prevention

- Working Mechanism

- Screw Mechanism with Rotary Valve

- Continuous vs Batch Operation

- Inline Continuous

- Automation Level

- Inverter Controlled Gearmotor

- Clogging Prevention

- Anti-clogging Device

- Inclined Installation

- Yes, for Uneven Sites

- Food safe compatibility

- Painted internal surfaces

- Hygiene standards

- Highest hygiene standards

- Corrosion resistance

- Stainless-steel construction

- Clogging prevention

- Device preventing clogging

- Inclination adaptability

- Inclined version for uneven sites

- Discharge method

- Rotary valve with pneumatic conveyor

- Tubular body design

- Variable pitch internal screw

- Construction material

- Stainless-steel (optional)

- Pitch Design

- Variable

- Material Construction

- Standard/Stainless Steel (optional)

- Safety Features

- Accident prevention systems

- Paint Type

- Food Safe