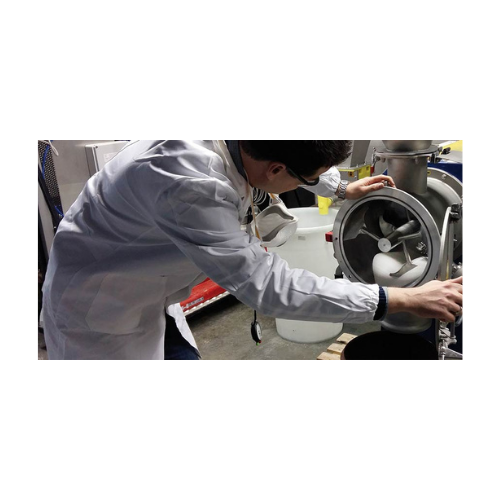

Laboratory batch mixer for small scale production

Achieve rapid and reproducible mixing results with this laboratory batch mixer, designed for precise material blending and small-scale production tasks. Ideal for environments that require accurate testing and development of new formulations across a variety of materials.

Mixes, Tests, and Produces Small-Scale Batches

The MLH Laboratory Batch Mixer from WAMGROUP is designed for precise and versatile mixing in pharmaceuticals, food, chemicals, and more. It operates through a mechanically generated fluidbed process, allowing reproducibility and seamless transition from laboratory to production scale. Supporting applications from tablet and capsule formation to cocoa and granule processing, it offers a capacity of 1 to 40 liters per batch. Equipped with a frequency inverter-controlled motor, it allows variable shaft speeds between 70 and 270 rpm, catering to diverse mixing needs. Available in 304L and 316L stainless steel, it withstands rigorous industrial usage. The MLH complements R&D processes with its easy-to-change mixing tools, optional high-speed chopper, and liquid injection capability, ensuring product integrity and process development efficiency. It supports small-scale operations with customizable features such as heating or cooling jackets and special surface treatments.

Benefits

- Ensures precise and reproducible mixing results, enhancing laboratory to production transition.

- Offers flexibility with interchangeable mixing tools and variable drum sizes.

- Minimizes product deterioration with controlled and gentle mixing processes.

- Facilitates easy cleaning and maintenance with accessible and replaceable internal components.

- Provides adaptability for diverse applications with customizable features like liquid injection and surface treatments.

- Applications

- Powder metallurgy, Sugar processing, Pesticide, Biscuit processing, Cosmetics, Soap, Food, Chemicals, Insecticide, Noodle making, Chocolate processing, Spices, Rubber, Resin, Cocoa, Animal feed, Coffee processing, Pasta, Convenience food, Varnish, Biochemical, Fertilizer, Plastics, Pharmaceuticals, Paint, Salt processing, Detergent

- End products

- Dog biscuits, Spaghetti, Pasta shells, Pvc granules, Npk fertilizers, Acrylic paints, Rubber tires, Protein bars, Curry powder, Laundry detergent, Wood varnish, Cocoa powder, Epoxy resin, Energy drinks, Face cream, Caster sugar, Syrups, Capsules, Bath soap, Insect sprays, Ready meals, Vaccines, Cat food, Composite materials, Ground coffee, Instant noodles, Metal powders, Table salt, Chemical formulations, Coffee granules, Chocolate bars, Tablets, Herbicides

- Steps before

- Grinding, Pasta, Noodle Making, Biscuit Processing, Cocoa, Chocolate Processing, Sugar Processing

- Steps after

- Packing, Fertilizer, Pesticide, Insecticide Processing, Paint, Varnish, Resin Processing, Detergent, Soap, Cosmetics Processing, Tablet Pressing

- Input ingredients

- pharmaceutical ingredients, food ingredients, chemical materials, biochemical substances, powder metallurgy materials, liquid additives

- Output ingredients

- homogeneous mixtures, processed pharmaceuticals, mixed food products, chemical compounds, biochemical mixtures, metallic powders

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Capacity

- 1 ~ 40 litres per batch

- Mixing speed

- 70 to 270 rpm

- Drum size

- 6, 12, 30, and 50 litres

- Material construction

- 304L / 316L stainless steel

- Automation

- Frequency inverter controlled

- Installation

- Free-standing

- Working Mechanism

- Mechanically generated fluidbed process

- Batch vs. continuous operation

- Batch

- Changeover Time

- Quick change of drum size

- Automation Level

- Motor controlled by frequency inverter

- Abrasion resistance

- High

- Biological compatibility

- Food grade

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- 304L / 316L stainless steel

- Density/particle size

- 0.5–2.5 g/cm³

- Applicability industries

- Pharmaceutical, food, chemical, biochemical, powder metallurgy

- Machine footprint

- Depends on configuration

- Drum size

- 6, 12, 30, 50 litres

- Discharge method

- Outlet spout

- Control panel type

- Frequency inverter

- Compact footprint

- Yes

- Construction material

- 304L / 316L stainless steel

- Heating/cooling option

- Jacketed mixing chamber

- Mixing shaft type

- Horizontal, easily replaceable

- Mixing tools available

- Ploughshare, toothed ploughshare, blade-type, toothed blade, ribbon

- Control panel type

- Frequency inverter control

- Mixing vessel options

- Quick release, different sizes

- Surface treatment

- Special surface treatment, mirror polishing, Teflon liner

- Heating/cooling options

- Jacketed mixing chamber

- Mixing tools variety

- Ploughshare, toothed ploughshare, blade-type, toothed blade, ribbon

- Chopper installation

- Option for high-speed chopper