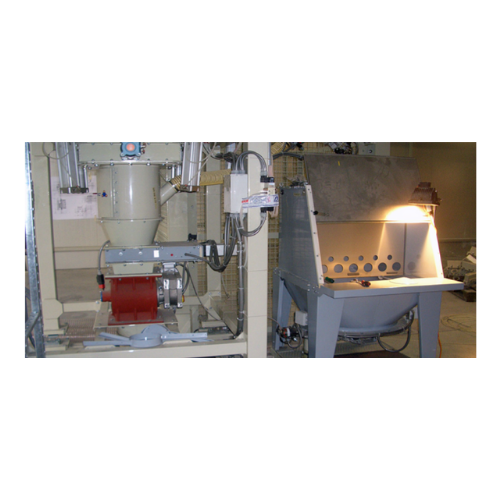

Manual bag opener for bulk solids discharging

Effortlessly open and empty bags while containing dust emissions, ensuring a clean and efficient processing environment for your bulk solids operations.

Opens, Empties, and Collects Dust from Bags

The Manual Bag Opener RSM from WAMGROUP streamlines material handling for industries ranging from food to chemicals. This user-oriented equipment features a compact design with easy access for cleaning. The RSM minimizes dust and material residue through a built-in fan-operated, air jet-cleaned dust collector, ensuring a cleaner processing environment. It accommodates diverse materials with options in carbon steel, 304L, and 316L stainless steel, and supports ATEX zone 22 applications. Its modular components make it adaptable across various pre-processing tasks, such as opening bags for wheat flour in milling or additives in chemical production. Optional enhancements include de-dusting filters and compatibility with the BINSWEEP Rotary Discharger for efficient downstream integration. The RSM’s robust design ensures durability and reliability, providing engineering support for process optimization.

Benefits

- Enhances safety and cleanliness with integrated dust collection, reducing airborne particulates.

- Saves floor space with a compact design, facilitating easy integration into limited spaces.

- Lowers maintenance time with easy access to internal parts for cleaning.

- Versatile material options ensure compatibility with diverse industrial requirements.

- Minimizes material waste with efficient bag opening and residue reduction.

- Applications

- Animal feed additives, Sugar processing, Pesticide, Rubber processing, Biscuit processing, Soap, Animal feed milling, Beverage processing, Pharmaceuticals processing, Cosmetics processing, Noodle making, Flour milling, Chocolate processing, Spices, Cocoa, Pasta, Convenience food, Varnish, Fertilizer, Resin processing, Baby food, Insecticide processing, Petfood, Bakeries, Fish food, Paint, Salt processing, Detergent, Plastics raw material processing, Breweries

- End products

- Spaghetti, Mosquito repellent, Dog kibble, Infant formula, Wheat flour, Body wash, Curry powder, Polycarbonate pellets, Craft beer, Wood varnish, Cocoa powder, Anti-aging cream, Chocolate chip cookies, Cornmeal, Vermicelli, Ibuprofen tablets, Car tires, Instant soup mixes, Apple juice, Granulated sugar, Acrylic paint, Cat food, Milk chocolate bars, Epoxy resin, Rye bread, Table salt, Ddt pesticide, Urea fertilizer, Dishwashing liquid, Pig feed

- Steps before

- Material Transportation, Material Storage, Bag Handling

- Steps after

- Dust Collection, Material Feeding, Waste Bag Compaction, Bulk Solids Discharging

- Input ingredients

- bagged materials, bulk solids, sacks, powders, granules

- Output ingredients

- empty bags, discharged bulk materials, collected dust

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Material

- Carbon steel, 304L / 316L stainless steel

- De-dusting filter

- Available with integrated or centralised dust suction

- Filter element options

- Cartridges, round bags, elliptical bags

- Filter surface area

- 3 to 22 m² (32 to 237 sq ft)

- Collecting hopper capacity

- Different capacity volumes

- Support feet adjustability

- Height adjustment available

- ATEX version

- Available for zone 22

- Built-in dust collector

- Fan-operated, air jet-cleaned

- Optional accessories

- Pneumatic vibrator, BINSWEEP Rotary Discharger fitting

- Automation level

- Manual

- Cleaning method

- Manual

- Batch vs. continuous operation

- Batch

- Space-saving design

- Compact

- Dust control

- Built-in air jet-cleaned dust collector

- Material residue minimization

- Modular component design

- User accessibility

- Easy and quick access for cleaning

- Filter integration

- Available with de-dusting filter or centralised dust suction

- Operator involvement

- Hands-on during bag slitting and emptying

- Height adjustment

- Support feet with adjustable height

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Bag type

- Manual bag dumping

- ATEX certification

- Zone 22

- FDA materials

- 304 L / 316 L stainless steel

- Machine footprint

- Compact, space-saving design

- Material

- Carbon steel, 304L / 316L stainless steel

- Height adjustment

- Support feet with height adjustment option

- Filter surface area

- 3 to 22 m² (32 to 237 sq ft)

- Discharge method

- Through hopper or BINSWEEP Rotary Discharger

- Dimensions

- Compact overall dimensions

- Customizable filter options

- Cartridges, round bags, elliptical bags

- ATEX version

- Available in ATEX version, zone 22

- Material Type

- Carbon steel, 304L / 316L stainless steel

- Filter Element Options

- Cartridges, round bags, elliptical bags

- De-dusting Filter

- Available with integrated or centralised dust suction

- Height Adjustment

- Support feet with height adjustment capability

- ATEX Version

- Available for zone 22

- Hopper Capacity

- Different volume capacities available

- Pneumatic Vibrator

- Option for specially equipped hoppers

- BINSWEEP Compatibility

- Option to fit special hoppers with BINSWEEP Rotary Discharger