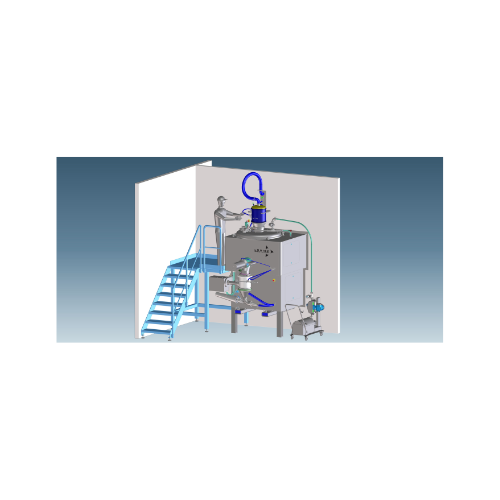

Mixing granulator for pharmaceutical and cosmetic industries

Achieve precise granulation and uniform mixing for high-quality tablet and cosmetic production, ensuring optimal texture and consistency with high-speed, GMP-compliant operation.

Mixes, Granulates, and Sieves Pharmaceutical and Cosmetic Products

The Lödige Mixing Granulator is engineered to meet the stringent demands of the pharmaceutical, cosmetics, and food industries. This high-shear mixer utilizes a sophisticated three-bladed tool rotating within a vertical, cylindrical vessel to achieve vortex-like circulation, ensuring rapid and uniform mixing and granulation. Equipped to handle pharmaceutical powders, granulated products, and more, it supports the creation of diverse end products such as tablets, facial powders, and seasoning blends. The mixer features automated liquid addition, either gravimetric or via pump, optimizing distribution, while an optional wet sieve on discharge ensures granule homogeneity. The PC/PLC-based control system, compliant with CFR-21 Part 11, offers intuitive operation with full process parameter visibility, ensuring precise batch documentation. Designed with a modular WIP system, it allows for efficient cleaning and maintenance. Compliance with GMP standards and available ATEX concepts provides assurance in controlled environments. Customizable options include a heating/cooling jacket, vacuum feeding, and integration with fluid bed processors, delivering adaptable solutions for varied production needs.

Benefits

- Ensures quick and consistent mixing and granulation, enhancing product quality and uniformity.

- Reduces labor costs through automated, intuitive PC/PLC-based controls that streamline operations.

- GMP-compliant design supports regulatory compliance for pharmaceutical production.

- Modular WIP system enables efficient and contamination-free cleaning, minimizing downtime.

- Adaptable for various production needs with customizable features and integration capabilities.

- Applications

- Granulated products, Tablet recipes, Cosmetics, Facial powders, Spices, Pharmaceutical products, Food products, Pharmaceutical powders

- End products

- Premix for spices, Nutritional supplements, Instant soup mixes, Granulated sugar, Tablets, Face powders, Effervescent tablets, Seasoning blends, Compact powders

- Steps before

- Extraction, Purification, Drying, Grinding

- Steps after

- Sterilization, Packing, Coating, Tablet Pressing

- Input ingredients

- pharmaceutical powders, cosmetics ingredients, food ingredients, tablet recipes, spice extracts

- Output ingredients

- granulated products, facial powders, homogeneous mixes, pharmaceutical granules

- Market info

- Loedige Process Technology is renowned for its expertise in industrial mixing, granulation, drying, and coating technologies, offering engineered-to-order solutions for various industries, including pharmaceuticals, chemicals, and food processing.

- Automation

- PC/PLC-controlled

- Batch documentation

- Hard and soft copies

- Temperature control

- Jacket for heating/cooling

- Feeding method

- Via vacuum

- Pressure shock resistance

- Up to 12 bar

- Liquid addition

- Gravimetric / Pump

- Granulate size distribution

- Wet sieve on discharge

- Chopper drive

- Separately driven

- Working mechanism

- High-shear mixing

- Integrated steps

- Mixing, Granulation, Sieving

- CIP/SIP

- Modular WIP system

- Batch vs. continuous operation

- Batch operation

- Automation level

- PLC / SCADA

- Temperature Control

- Temperature control jacket

- Liquid addition method

- Gravimetric / Pump

- Mixing tool movement

- Vortex-like circulation

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Footprint

- Compact design

- Mixing Vessel Shape

- Vertical, cylindrical

- Mixing Tool Shape

- Three-bladed

- Feed Method

- Automatic liquid addition

- Discharge Method

- Integrated sieve

- Control Panel Type

- PC/PLC-based control system

- Heating/Cooling

- Temperature control jacket

- Vacuum Feeding

- Available

- Control panel type

- PC/PLC-based with SCADA system

- ATEX concepts

- Customised

- Liquid addition method

- Gravimetric or pump

- Jacket options

- Heating/Cooling

- Vacuum feeder option

- Available

- Mixing tool

- Raisable

- Pressure shock resistance

- Up to 12 bar

- Connection to other equipment

- Fluid bed processor