High-pressure roller compactors for chemical, food, and minerals industries

Achieve precise particle compaction and briquetting with robust, energy-efficient high-pressure rollers, enhancing flow properties and reducing dust across a seamless production line.

Compacts and Briquettes Diverse Materials Efficiently

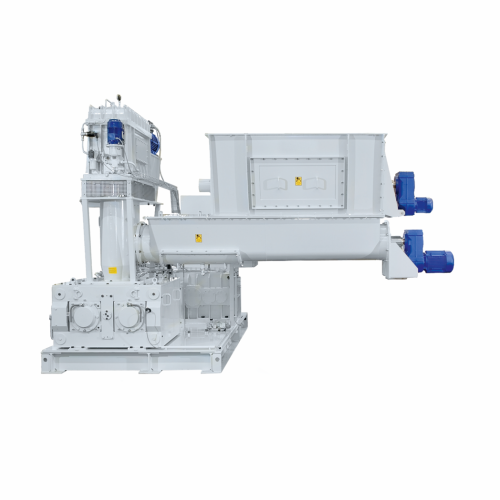

The Series ARC MS and ARC CS Kompaktor Roller Presses, engineered by Hosokawa Alpine, deliver exceptional compaction and briquetting capabilities tailored for diverse industries such as chemicals, food, and recycling. Utilizing counter-rotating rollers, these machines press fine powders into solid forms like flakes and briquettes, with the ARC MS equipped to handle abrasive materials as a high-pressure roller mill. The ARC MS boasts a through-put of 0.5 to 250 tons per hour, while the ARC CS is ideal for smaller production quantities of up to 0.8 tons per hour, featuring quick tool changes and flexible adaptation to production conditions. Both series enhance production lines by improving material flow properties and reducing dust. They offer energy-efficient processes, support various feed methods, and are available in ATEX-certified, dust-tight, and gas-tight configurations for inert operation. Components in contact with products are made from stainless steel or special wear-resistant materials, ensuring longevity and compatibility. Customization options and configuration support further adapt these systems to specific operational needs.

Benefits

- Enhances material flow and uniformity, reducing downstream processing issues.

- Minimizes dust pollution, creating a safer and cleaner work environment.

- Customizable for specific material properties, ensuring product consistency.

- Quick tool changes enhance production flexibility and reduce downtime.

- Energy-efficient operation lowers operational costs and environmental impact.

- Applications

- Dishwashing powder, Cosmetics, Lithium-ion batteries, Crop protection agents, Recycling composite materials, Technical ceramic, Powder coating, Sweeteners, Talc, Recycling extruded materials, Chemicals, Calcium carbonate (gcc), Flame retardants, Fertiliser, Medicinal herbs, Luxury foods, Low energy solutions, Hapi, Post consumer recycling (pcr), Additive manufacturing metal, Spices, Tea, Recycling plastic mouldings, Animal feed, Additive manufacturing polymer, Titanium dioxide, Industrial wax, Recovered carbon black, Special flours, Sugar, Cell culture media, Cocoa processing, Cable recycling, Grinding of rubber, Api - inhaler, Lignin, Film recycling, Thickening agents, Roots, Protein shifting, Hard minerals, Tablets, Lactose, Dairy products

- End products

- Tire carbon black, Confectioner's sugar, Bio-composite boards, Ginseng root extract, Pea protein isolate, Vitamin tablets, Chocolate liquor, Battery electrodes, Fiber-reinforced panels, Poultry feed, Whey protein powder, Recycled pet pellets, Encapsulation tablets, Automotive plastic parts, Plastic film granules, Detergent granules, Candle wax, Bioplastics, Polyurethane coatings, Black tea leaves, White truffle oil, Ground rubber mulch, Ammonium nitrate pellets, Algae-based omega-3 supplements, Aspartame powder, Moisturizing creams, Sterile syringes, Kiln-dried clay tiles, Gluten-free flour, Cornstarch, Plastic casings, Herbicides, Guar gum, White pigment for paint, Copper wire insulation

- Steps before

- Grinding, Mixing, Feeding, Drying, Purification

- Steps after

- Compaction, Briquetting, Pelletizing, Packaging, Storage

- Input ingredients

- fine-grained powder, lignin, fertiliser, sponge iron, coal, metal dust, limestone, talc, protein concentrate

- Output ingredients

- compacted material, briquettes, granules, flakes

- Market info

- Hosokawa Alpine is known for its expertise in manufacturing advanced process equipment and systems for powder and particle processing technology. It has a strong reputation for innovation, quality engineering, and customer-focused solutions in various industries.

- Capacity

- 0.5 t/h to 250 t/h

- Pressing forces

- Up to 99% of pure density

- Roller type

- Fixed and loose roller

- Pressing mechanism

- Hydro-pneumatic spring system

- Construction material

- Normal or stainless steel

- Roller mounting

- Tapered roller bearings

- Throughput capacity

- High

- System design

- Compact and space-saving

- Control system

- Quick tool changes

- Material feeding method

- Vertical/horizontal screw, gravity, or vacuum

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compacting level

- Briquettes or granules

- Agglomeration risk

- Reduced during compaction

- ATEX certification

- Yes

- CE marking

- Yes

- FDA compliance

- Yes

- FDA materials

- Yes

- GMP Compliance

- Yes

- Discharge method

- Vertical screw feed, horizontal/vertical screw feed, multiple screw feeds, gravity feed or vacuum venting

- Roller design and surface materials

- Various roller surfaces as well as segmented rollers

- Roller bearing system

- Tapered roller bearings for axial and radial force absorption

- Press frame system

- Hinged press frame system

- Hydro-pneumatic spring system

- Adjustable pressing force

- Feed system configuration

- Vertical screw feed, horizontal/vertical screw feed, multiple screw feeds, gravity feed, vacuum venting

- Material contact options

- Parts in contact with the product are made of normal or stainless steel

- Wear resistance

- Special materials for high wear resistance

- Operation mode options

- Dust-tight and gas-tight (inert operating mode possible)