Pneumatic hammers for aiding material flow

Optimize material flow and eliminate blockages in your processing line with pneumatic hammers, perfect for reducing downtime in systems handling challenging powders that tend to pack or stick.

Generates Impact to Aid Material Flow

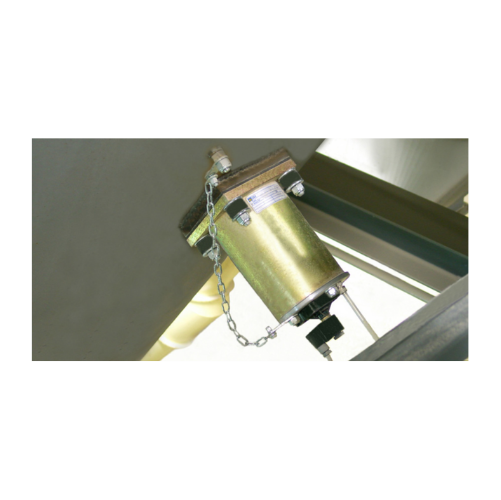

The MARTSHOCK PS Single Impact Pneumatic Hammer from WAMGROUP is engineered to enhance material flow in challenging industrial operations. This equipment emits a powerful single impact, aiding in the prevention of material packing and eliminating bridging or rat-holing in silos and hoppers without requiring wall drilling. Ideal for applications in ready-mix concrete and food processing, it operates at pressures between 3 and 6 bar, in intermittent modes, promoting effective flow of powders like flour and cement. It integrates easily into existing systems with a simple mounting plate and is suitable for both indoor and outdoor environments due to its robust, galvanized steel construction. Available in three sizes, the MARTSHOCK PS meets ATEX certification for explosive atmospheres and includes options for different voltage coils and noise reduction kits, enhancing safety and operational flexibility.

Benefits

- Ensures consistent material flow, reducing production interruptions caused by packing or bridging.

- Enhances operational flexibility with ATEX compliance for use in explosive environments.

- Minimizes installation time with easy mounting and integration into existing structures.

- Reduces maintenance demands with a robust design suitable for harsh conditions.

- Lowers noise pollution with optional noise reduction kits.

- Applications

- Sugar processing, Pesticide, Ready-mix concrete production, Rubber processing, Biscuit processing, Animal feed additives processing, Soap, Bakery plants, Drymix building materials processing, Animal feed milling, Chemical ad-mixtures for building, Pharmaceuticals processing, Plastics processing, Cosmetics processing, Iron and steel mills, Flour milling, Chocolate processing, Spices, Construction, Rice milling, Glass processing, Rubber, Cocoa, Coffee processing, Convenience food, Varnish, Fertilizer, Resin processing, Plastics recycling, Foundries, Precast concrete production, Petfood, Bakeries, Insecticide processing, Fish food, Paint, Salt processing, Detergent, Breweries, Coking plants

- End products

- Kibbles, Steel billets, Face creams, Varnish finishes, Concrete blocks, Rubber sheets, Beer, Spice blends, Cocoa powder, Epoxy resin, Paint coatings, Fish pellets, Pills, Biscuit cookies, Recycled plastic resins, Vitamin-enriched animal feeds, Roasted coffee beans, Plastic pellets, Bath soap, Ready meals, Dry mortar mix, Building chemicals, Pest control liquids, Refined sugar, Cattle feed pellets, Rice grains, Fertilizer granules, Table salt, Cast iron products, All-purpose flour, Bread loaves, Dishwashing liquid, Precast concrete panels, Chocolate bars, Coke production, Glass bottles

- Steps before

- Storage, Conveying, Mixing, Powder Filling

- Steps after

- Bulk Discharging, Silo Safety Monitoring, Packaging, Distribution

- Input ingredients

- powder, materials prone to packing, materials prone to sticking, materials prone to bridging, rat-holing materials

- Output ingredients

- free-flowing materials, resolved material flow, unclogged hoppers, enhanced material discharge

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Pressure Range

- 3 to 6 bar (44 ~ 87 PSI)

- Material

- Galvanized steel POM

- Size

- Available in three different sizes

- Noise Reduction

- ATEX KIT plate (ATEX II3D cT(x))

- Automation

- Fully pneumatic kit

- Mounting Method

- Welding on cone or wall with safety chain

- Operational Environment

- Suitable for outdoor and indoor applications

- Working pressure range

- 3 to 6 bar (44 ~ 87 PSI)

- Application environment

- Indoor/Outdoor

- Intermittent operation

- Required

- Installation method

- Mounted on plate, welded

- Automation level

- Progressive activation of multiple hammers

- Vibration mechanism

- Single impact shockwave

- Noise Reduction

- Available with ATEX KIT

- Abrasion resistance

- Able to handle abrasive materials

- Biological compatibility

- 0

- Cleanability

- 0

- Corrosive resistance (e.g. acids)

- 0

- Density/particle size

- Handles compacted powders and granules

- ATEX certification

- II3D cT(x)

- Material

- Galvanized steel, POM

- Mounting

- Welded on wall with a mounting plate

- Installation Method

- Weld-mounted with safety chain

- Size Variants

- Three different sizes

- Voltage Coils

- 24 V DC/AC to 230 V (ATEX compliant)

- Noise Reduction Kit

- Available

- ATEX Compliance

- ATEX II3D cT(x)

- Timer

- Adjustable period, min 30 sec

- Pneumatic Kit

- Fully available