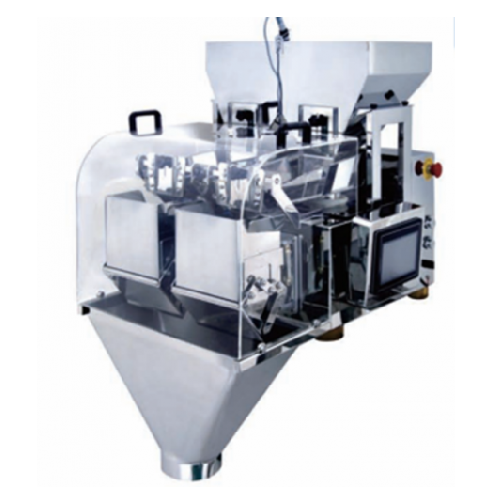

Linear weigher for accurate food portioning

Ensure precise weight control for snacks and confectioneries with our advanced linear weigher, designed for seamless integration in both manual and automated operations.

Weighs and Feeds Dry Products Accurately

The JW-AX2 Linear Weigher from The Food Machinery Company is a versatile solution for precise weighing needs in the food, snack, and confectionery industries. This equipment uses vibratory conveyors to efficiently transport products like potato chips and gummy bears from a common hopper to weigh bins. The computerized control system ensures rapid feeding that shifts to trickle feeding as the target weight nears, optimizing accuracy. With outputs ranging from 8 to 50 deposits per minute and available in various configurations of weigh heads (ranging from 500ml to 25ltr), it accommodates a wide range of food products. The JW-AX2 can operate as a stand-alone unit with manual foot pedal control or be integrated seamlessly with automatic bagging machines, facilitating both manual and automatic operations. Built with stainless steel construction, it offers durability and easy maintenance, with options for smooth, dimpled, or Teflon-coated contact parts to suit different product characteristics. The model includes Wash Down options for enhanced hygiene and cleanliness, a crucial feature in food production environments.

Benefits

- Enhances accuracy in weighing, minimizing product giveaway and maximizing profitability.

- Offers flexible integration options, compatible with both stand-alone and automatic systems.

- Reduces labor costs with user-friendly software and optional manual foot pedal control.

- Facilitates easy cleaning and maintenance with durable stainless steel construction and Wash Down capability.

- Adapts to a wide range of product sizes and types, from fine granules to larger snack items.

- Applications

- Snacks, Sugar, Dry free flowing products, Sweets, Rice, Fine granular products, Salt

- End products

- Jasmine rice, Gummy bears, Table salt, Trail mix, Jelly beans, Potato chips, Granola, Basmati rice, Caster sugar, Popcorn

- Steps before

- Conveying, Granular Product Feeding

- Steps after

- Manual Bag Filling, Automatic Bagging, Packing

- Input ingredients

- salt, sugar, rice, fine granular products, sweets, snack products, dry free flowing products

- Output ingredients

- weighed salt, weighed sugar, weighed rice, weighed sweets, weighed snack packages

- Market info

- The Food Machinery Company Ltd. is known for manufacturing bespoke food processing equipment, like conveyors and mixers, offering engineering expertise for industrial-scale food production, backed by a reputation for quality and tailored solutions in the UK and international markets.

- Output speed

- 8 - 50 deposits per minute

- Material Construction

- Stainless steel

- Weigh head versions

- Two head

- Four head

- 500ml, 3ltr

- Product Type Suitability

- Dry free flowing products

- Surface Options

- Smooth, Dimpled, Teflon coated

- Weight Feed Method

- Vibratory conveyors

- Control System

- Computerized controls

- Operational Mode

- Stand-alone/Automatic

- Feeding Type

- Rapid and Trickle Feed

- Weighing Heads

- Two or Four Head Versions

- Product Compatibility

- Dry Free Flowing Products

- Cleaning Protocol

- Wash Down Models Available

- Output speed

- 8 - 50 deposits per minute

- Program Memory

- Detailed Production Records

- Contact Parts

- Smooth/Dimpled/Teflon Coated

- Manual Control Option

- Foot Pedal Control

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product Type

- Dry, free-flowing products

- Particle Size

- Fine granular to larger items

- Abrasiveness

- Yes

- Construction Material

- Stainless steel

- Contact Parts

- Smooth, Dimpled, or Teflon coated

- Head Versions

- Two head (4.5L, 15L, 25L) / Four head (500ml, 3L)

- Discharge Method

- Vibratory conveyors

- Construction material

- Stainless steel

- Contact part coating

- Smooth / Dimpled / Teflon coated