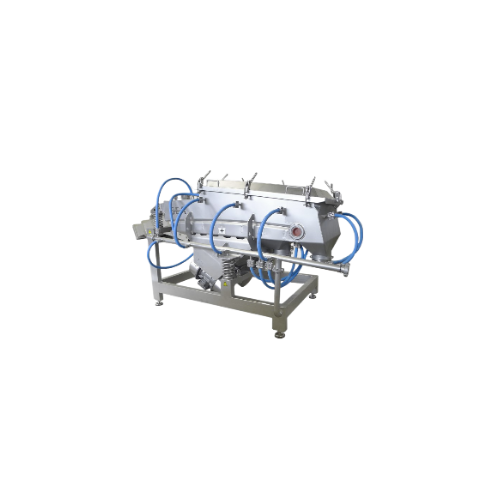

Industrial sifters for beverage processing

Optimize your beverage production with precisely engineered sifters that ensure fine grading and efficient separation, keeping ingredients pure and operations seamless during continuous 24/7 processes.

Processes and Separates Ingredients for Diverse Applications

The GEA Scan-Vibro Vibratory Sifters are engineered to tackle the complex demands of both beverage and food production lines. These sifters excel in gently processing materials, using a combination of oscillation and vibration to maintain product integrity while achieving optimal separation and grading. Applications extend across industries, from processing brewers’ yeast and freeze-dried coffee to dewatering chemical and dairy products. Designed for continuous 24/7 operation, they ensure high efficiency and low power consumption. Equipped with a tool-free screen replacement and CIP (Clean-In-Place) compatibility, these sifters facilitate easy maintenance and quick changeovers for different product types. Built from stainless steel and compliant with industry standards such as USDA 3-A and EHEDG, they withstand rigorous production environments. The option for manual or pneumatic screen tensioning systems and mobile support frames further enhances versatility, making them adaptable to your unique processing needs.

Benefits

- Minimizes production downtime with continuous 24/7 operation.

- Reduces operating costs through low power consumption.

- Enhances product quality with gentle material handling.

- Facilitates rapid changeovers with tool-free screen replacement.

- Meets stringent hygiene standards, supporting compliance with food and beverage regulations.

- Applications

- Wood pellets, Cheese, Fish flour, Fish feed, Minerals, Seeds, Dairy, Cement, Food, Fish, Ready-to-drink tea, Household waste, Freeze-dried coffee, Animal feed, Sugar, Pet food, Frozen vegetables, Fertilizer, Chemical, Salt, Recycling, Pharmaceuticals, Beverage, Meat, Cereals, Vegetables, Poultry, Brewers' yeast

- End products

- Gypsum powder, Infant formula, Penicillin tablets, Sunflower seeds, Municipal solid waste, Chicken nuggets, Salmon fillets, Breakfast cereal flakes, Diced carrots, Kibble, Wood briquettes, Portland cement, Cheddar cheese, Fish meal, Frozen spinach, Organic compost, Lager beer, Ground beef, Alfalfa pellets, Recycled plastic pellets, Lactose-free milk, Kombucha, Polyurethane foam, Table salt, Iced tea, Castor sugar, Surimi powder, Instant coffee granules

- Steps before

- Purification, Dewatering, Processing yeast, Freeze-drying coffee

- Steps after

- Packing, Sterilization, Removing unwanted particles

- Input ingredients

- brewers’ yeast, freeze-dried coffee, ready-to-drink tea, ingredients

- Output ingredients

- dewatered ingredients, processed brewers’ yeast, fine graded freeze-dried coffee, tea leaves removed from ready-to-drink tea

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Operation Temperature Range

- -20 to +55 °C

- Screening Area

- 0.5-3.0 m²

- Compliance

- USDA 3-A, EHEDG, ATEX

- Cleaning Method

- CIP-compatible, Screen cleaning system

- Energy Consumption

- Low power consumption

- Motor Type

- Lubrication-free

- Material

- Stainless steel

- Screen Tensioning System

- Manual or pneumatic

- Mobility

- Support frame with wheels

- Vibration Frequency

- Adjustable

- Screen Mesh

- Metal detectable

- Finish Grades

- 1.3–0.2 µm

- Working Mechanism

- Oscillation and frequency of vibration

- Automation Level

- Manual / PLC

- Batch vs. Continuous Operation

- Inline Continuous

- CIP/SIP

- CIP Compatible

- Cleaning Method

- Tool-free screen replacement

- Energy Efficiency

- Low power consumption

- Operation Conditions

- –20 to +55 °C

- Screen Cleaning System

- Prevents blinding

- Abrasion resistance

- Yes

- Biological compatibility

- Complies with USDA 3-A

- Cleanability

- Easy to clean (CIP-compatible)

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Density/particle size

- Wide range, suitable for different sifter mesh sizes

- Machine footprint

- Compact

- Screening area

- 0.5–3.0 m²

- Screen cleaning system

- Automatic

- Tool-free screen replacement

- Yes

- Material

- Stainless steel

- Temperature range

- –20 to +55 °C

- Mobility

- Wheeled support frame

- Discharge method

- Side discharge

- Top covers

- Large with gas struts

- Customization

- Tailor-made to suit application

- Compliance

- USDA 3-A, EHEDG, ATEX

- Screen cleaning system

- Available to prevent blinding

- Screen mesh size

- Variety available for different product types

- Screen replacement mechanism

- Tool-free design for quick changeover

- Screen tensioning system

- Manual or pneumatic

- Surface finish

- Various grades available

- Can be polished from 1.3–0.2 µm

- Mobility

- Support frame mounted on wheels

- Gas struts

- Available for large top covers

- Metal detectable screen mesh

- EN 1.4016/AISI 430