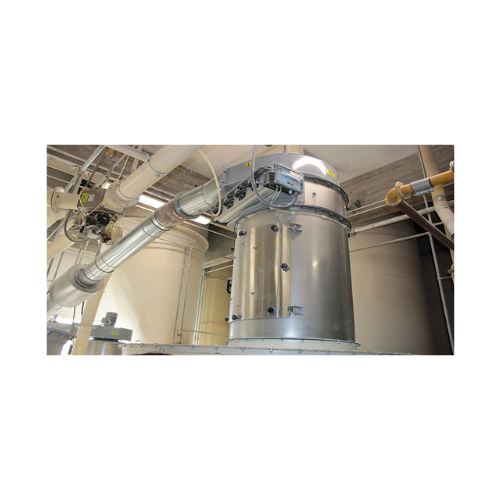

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to manage dust particles efficiently in food processing lines while ensuring compliance with stringent hygiene standards.

Collects and Filters Food-Grade Dust

The WAMFLO Food FN200 and FN200X from WAMGROUP are flanged round food-grade dust collectors specially designed for stringent food processing requirements. With a cylindrical stainless-steel casing and vertically mounted food-grade bag filter elements, they ensure zero-dust residue, maintaining hygiene and product integrity. Suitable for applications such as flour and rice milling, biscuit processing, and spice manufacturing, they effectively filter dust particles from air currents using bag-type filter elements. The integrated compressed air jet cleaning system guarantees high efficiency, reducing maintenance and saving on total plant cost ownership. The FN200X model is ATEX-certified for explosive environments, while both models comply with EU Food Regulations. Featuring easy access for filter replacement and a modular electronic control panel, these collectors integrate seamlessly into automated operations, offering versatility across various food production lines.

Benefits

- Ensures compliance with hygienic standards using food-grade and ATEX-certified components.

- Minimizes maintenance with efficient compressed air cleaning system.

- Facilitates quick and easy filter replacement reducing downtime.

- Lowers total plant ownership costs through modular control and reduced emissions.

- Adapts to various production requirements with customizable configurations.

- Applications

- Sugar processing, Pesticide, Rubber processing, Biscuit processing, Soap, Bakery plants, Beverage processing, Pharmaceuticals processing, Plastics processing, Cosmetics processing, Noodle making, Flour milling, Chocolate processing, Spices, Rice milling, Rubber, Cocoa, Coffee processing, Pasta, Convenience food, Varnish, Fertilizer, Resin processing, Plastics recycling, Baby food, Insecticide processing, Bakeries, Paint, Salt processing, Detergent, Plastics raw material processing, Breweries

- End products

- Spaghetti, Lager, Powdered sugar, Npk fertilizer, Curry powder, Polyethylene pellets, Chocolate chip cookies, Dark chocolate bars, Croissants, Baby milk formula, Instant soup mixes, Mosquito repellent spray, Ramen noodles, Acrylic paint, Polyurethane varnish, Recycled rubber mulch, Ground coffee, Liquid soap, Pain relief tablets, Epoxy resin, Plastic bottles, Bread loaves, Sea salt, Rice flour, Ale, Lipstick

- Steps before

- Grinding, Drying, Material Conveying

- Steps after

- Packing, Sterilization, Quality Control

- Input ingredients

- wheat, beans, sugar, rice, coffee, cocoa, diet foods, chilli pepper

- Output ingredients

- clean air

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Filter surface

- 1 ~ 21 m² (11 ~ 226 sq ft)

- Air volume

- 60 ~ 2, 700 m³/h (35 ~ 1, 590 cfm)

- Compressed air pulse-jet cleaning pressure

- 5 ~ 6 bar

- Dust temperature

- -20 ~ 80 °C (-4 ~ 176 °F)

- Cylindrical casing material

- Stainless-steel

- Cleaning system

- Compressed air pulse-jet

- Control panel

- Multifunctional, multi-voltage electronic control panel

- Explosion safety

- ATEX explosion panel

- Cleaning method

- Easy access for cleaning

- CIP/SIP

- Quick access for maintenance

- Automation level

- Modular electronic control panel

- Automation level

- Integrated compressed air jet cleaning

- Batch vs. continuous operation

- Configurable for venting, suction, and vacuum

- Changeover time

- Filter element replacement in minutes

- Energy efficiency

- Minimized maintenance and reduced plant cost ownership

- Hygienic design

- Zero-dust residue design

- Safety features

- Captive twist lock system

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Dust Type

- Food-grade

- Filter surface area

- 1 ~ 21 m² (11 ~ 226 sq ft)

- Cylindrical stainless steel casing

- Yes

- Compressor air usage

- 5 ~ 6 bar

- Air volume

- 60 ~ 2, 700 m³/h (35 ~ 1, 590 cfm)

- Temperature range

- -20 ~ 80 °C (-4 ~ 176 °F)

- Flanged bottom ring

- Welded

- Casing material

- 304/316 stainless-steel casing and seal-frame

- Customizable features

- Fan or connecting flange to centralized dust suction

- Application adaptability

- Insertable and/or vacuum versions available

- Operating environment

- Suitable for application in internal Zone 20