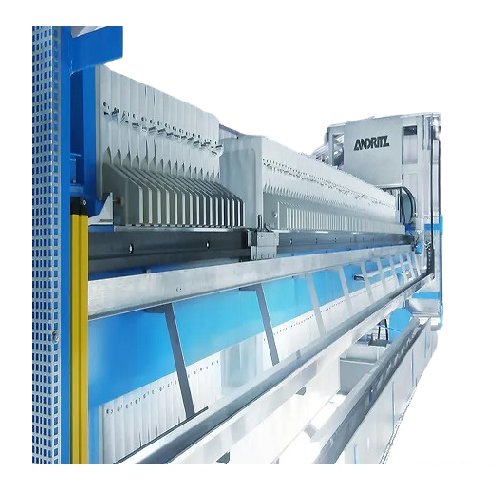

Industrial filter press for dewatering and filtration

Optimize your dewatering and filtration needs with a highly adaptable press system, enhancing process control and efficiency across diverse applications with modular and customizable options.

Processes Filtration and Dewatering Tasks Efficiently

The ANDRITZ sidebar and overhead filter presses are engineered for optimal filtration and dewatering in a variety of industries such as mining, chemical processing, and food production. Utilizing innovative membrane and chamber technologies, these presses ensure reliable separation of solids from liquids, crucial for producing high-quality end-products like copper concentrate and refined vegetable oils. They operate with filtration pressures ranging from 7 to 30 bar and accommodate diverse production scales with sizes up to 2,500 x 2,500 mm. Designed for seamless integration into existing systems, they offer flexibility with manual to fully automatic configurations and remote management through the Metris addIQ automation system. Energy efficiency is enhanced with low power consumption, and material variants include stainless steel for exceptional corrosion resistance. Easy customization and a modular design approach allow for tailored solutions meeting specific operational requirements while minimizing downtime with maintenance-friendly features.

Benefits

- Enhances operational efficiency with customizable automation levels.

- Minimizes energy use through optimized motor controls.

- Provides reliable separation under varying process conditions.

- Facilitates quick adaptation to different applications with modular design.

- Supports stringent safety and quality standards with corrosion-resistant materials.

- Applications

- Functional ingredients, Aluminium, Fgd (flue gas desulphurization), Metal hydroxide, Cosmetics, Starches, Minerals, Pigments, Soda ash, Sewage treatment, Dairy, Dyes, Coal, Petrochemicals, Potash, Mineral oil, Natural rubber, Bioplastics, Vegetable oil, Sugar, Specialty chemicals, Agrochemicals, Salt, Calcium carbonate, Pharmaceuticals, Beverages, Industrial wastewater, Clay, Protein, Nutraceuticals, Animal processing, Iron ore, Copper, Phosphate

- End products

- Specialty chemical additives, Bioplastic resins, Soda ash (sodium carbonate), Drinking water, Beer, Copper concentrate, Active pharmaceutical ingredients, Wine, Potash granules, Iron ore pellets, Fructose syrup, Soy protein isolate, Tapioca starch, Whey protein, Branded cosmetics, Corn starch, Refined vegetable oils, Natural rubber sheets, Animal fats, Milk powder, Aluminium powder, Calcium carbonate powder, Fish protein, Textile dyes, Petrochemical solvents, Coal slurry, Clarified wastewater, Organic pigments, Lactose, Phosphate rock

- Steps before

- Mixing, Sludge preparation, Pre-conditioning, Grinding, Purification

- Steps after

- Drying, Dehydration, Packing, Post-treatment, Wastewater treatment

- Input ingredients

- industrial wastewater, sludge, metal hydroxide, textile wastewater, food industry wastewater, iron and steel industry wastewater, potable water, sewage, solid waste, biomass, stone processing sludge, agrochemicals, mineral oil, natural rubber, bioplastics, petrochemicals, pharmaceuticals, cosmetics, pigments, dyes, soda ash, specialty chemicals, animal processing materials, beverages, dairy products, baby food, functional ingredients, industrial fermentation, nutraceuticals, starches, protein, sugar, vegetable oil, tailings, battery minerals, coal, iron ore, aluminium, calcium carbonate, clay, copper, flue gas desulphurization, phosphate, potash, salt

- Output ingredients

- filtered water, dewatered sludge, concentrated chemicals, clarified liquid, solid cake, processed minerals, purified beverages, refined oil, dry biomass, cleaned effluent

- Market info

- ANDRITZ is known for its expertise in supplying industrial ETO equipment and services, specializing in sectors like pulp and paper, hydropower, and metals. It has a strong reputation for innovation and engineering excellence.

- Filter Press Type

- Sidebar / Overhead

- Filter Press Size

- Up to 2, 500 x 2, 500 mm

- Filtration Area

- Up to 2, 000 m²

- Filtration Pressure

- 7 to 30 bar

- Plate Type

- Chamber / Membrane / Frame

- Automation

- Full automation with Metris addIQ

- Energy Source Flexibility

- Various

- Operation Type

- Manual to Fully Automatic

- Process Parameter Optimization

- Dynamic squeezing time, Filling level

- Machine Throughput

- High throughput per machine

- Working mechanism

- Sidebar and overhead designs

- Automation level

- Manual / Fully automatic

- Energy sources

- Multiple energy sources

- Operation mode

- Batch

- CIP/SIP

- Possible

- Changeover time

- Short

- Process reliability

- High

- Maintenance

- Maintenance-friendly

- Remote plant management

- Available

- Upgradeability

- Easy to upgrade

- Process monitoring

- Via IIoT/Metris addIQ

- Integration with Industry 4.0

- Prepared

- Filtration pressure range

- 7 to 30 bar

- Biological compatibility

- Food and pharmaceutical applications

- Corrosive resistance (e.g. acids)

- Stainless steel cladding, rubber lining or PP coating

- Filter type

- Chamber / Membrane / Plate and Frame

- Filter plate size

- Up to 2, 500 x 2, 500 mm

- Filtration area

- Approx. 1, 300 m² - 2, 000 m²

- Filter type

- Chamber, Membrane, Frame

- Filtration pressure

- 7 to 30 bar

- Discharge method

- Overhead and Sidebar design

- Customization potential

- Fully customizable for specific applications

- Filter press design

- Sidebar / Overhead

- Filter element type

- Chamber / Membrane

- Plate size

- Up to 2, 500 x 2, 500 mm

- Plate access

- Side / Overhead

- Safety features

- Safety guards, Splash guards

- Lining options

- Rubber / PP

- Scraper/vibrating device

- Optional