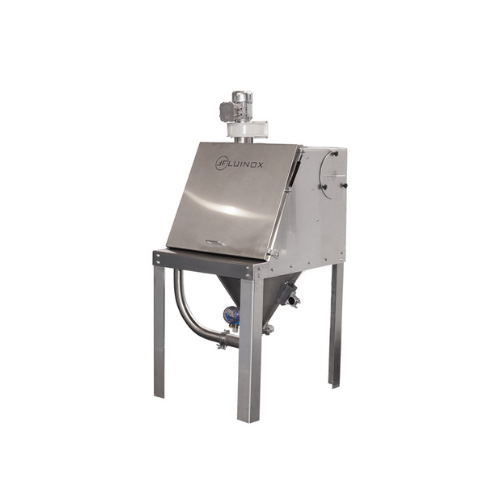

Bag dump station for handling solid foodstuffs

Efficiently manage manual dosing of solid foodstuffs and powders with this ergonomically designed station, minimizing dust and enhancing safety in your workflow. Ideal for precise ingredient introduction to varied production lines.

Unloads and Doses Solid Powders and Granules

The Bag Dump Station from INOXPA offers an ergonomic and efficient solution for manually unloading and dosing solid materials such as powders and granules, suitable for food, pharmaceutical, and chemical industry applications. This equipment features an infeed hopper with a dust trapping system, minimizing dust exposure during loading. A pneumatic vibrator and rotary valve facilitate smooth material transfer for doses and mixing in production lines. Designed to handle diverse solid foodstuffs, grains, and chemical powders, it supports upstream processes like unloading and downstream mixing or dispensing. The station integrates seamlessly with solids handling systems, enhancing operational efficiency with manual and pneumatic operations. Constructed from AISI 316 and 304 stainless steel with FDA-compliant seals, it ensures high corrosion resistance, making it ideal for sensitive material applications. Optional enhancements include rotary valves and fine mesh sieves to tailor the setup to specific industry standards and production needs.

Benefits

- Enhances ergonomic operation and safety with a dust trapping system, reducing operator exposure.

- Supports versatile applications, handling a wide range of powders and granules in food and chemical industries.

- Improves operational efficiency with seamless integration into existing solids handling systems.

- Ensures durability and compliance with robust stainless steel construction and FDA-compliant materials.

- Customizable options allow for precise adaptation to specific production requirements, optimizing process flow.

- Applications

- Chemical powders, Sugar, Grain, Food industry, Flour, Starch, Solid foodstuffs, Powders, Salt, Non-food applications

- End products

- Confectionery sugar, Corn starch, Gluten-free flour, Sea salt flakes, Non-dairy creamer, Protein supplement powders, Bakery premixes, Beverage mixes, Industrial salt, Chemical fertilizers, Soy protein isolate, Cement powders, Tapioca flour

- Steps before

- Purification, Grinding, Mixing, Pre-weighing

- Steps after

- Blending, Packing, Sieving, Transportation

- Input ingredients

- sugar, flour, salt, solid foodstuffs, pre-weighed sacks, bags, powder form, flour, starch, leaf, grain

- Output ingredients

- solid material, powder, product lines, minor ingredients, production line

- Market info

- INOXPA is known for its expertise in manufacturing stainless steel components and equipment, particularly for the food, dairy, cosmetic, and pharmaceutical industries. They are reputed for high-quality, hygienic, and reliable processing solutions.

- Capacity

- 3 T/hour*

- Flow rate

- Depends on product and conditions

- Material types

- Flour, starch, leaf, grain, sugar, salt

- Bag size

- Approximately 25 kg

- Material transfer assistance

- Pneumatic vibrator, rotary valve

- Safety system

- Pneumatic cylinders, shock absorbers

- Dust trapping system

- Fan with filtering basket, polyester filter

- Material contact parts

- AISI 316

- Other stainless steel parts

- AISI 304

- Seals material

- TR08 FDA cellular silicone

- Bag emptying method

- Rotary valve or direct transportation

- Pressure options

- Vacuum or under pressure

- Bag emptying flow rates

- 3 T/hour*

- Ergonomic solution

- Yes

- Manual dosing capability

- Yes

- Multi-product line integration

- Yes

- Dust trapping system

- Yes

- Vibrator for material transfer

- Yes

- Automation level

- Manual / Automatic options

- Safety features

- Shock absorbers, pneumatic cylinders

- Flow rate

- 3 T/hour*

- Transportation method

- Vacuum / Pressure

- Bag size compatibility

- 25 kg

- Raw material type compatibility

- Flour, starch, leaf, grain, sugar, salt

- Abrasion resistance

- AISI 316, AISI 304

- Corrosive resistance (e.g. acids)

- AISI 316

- Biological compatibility

- TR08 FDA cellular silicone

- Cleanability

- Stainless steel components

- Density/particle size

- Flour, starch, sugar, salt

- Discharge method

- Rotary valve / Direct transportation

- Protective grid

- Inside the unit

- Front hatch closing mechanism

- Shock absorbers safety feature

- Pneumatic Vibrator

- Aids raw material transfer

- Rotary Valve

- Controls bag emptying flow rates

- Front Hatch Safety System

- Pneumatic cylinders

- Filtering Basket

- Polyester filter

- Dust Trapping System

- Fan with a filtering basket

- Extraction System

- Extractor or sieve fitting

- Materials

- AISI 316 and AISI 304 stainless steel

- Non-standard ATEX Marking

- Available for custom configurations

- Bags / Product Compatibility

- Flour, sugar, starch, grain, salt

- Bag Emptying Flow Rates

- 3 T/hour*