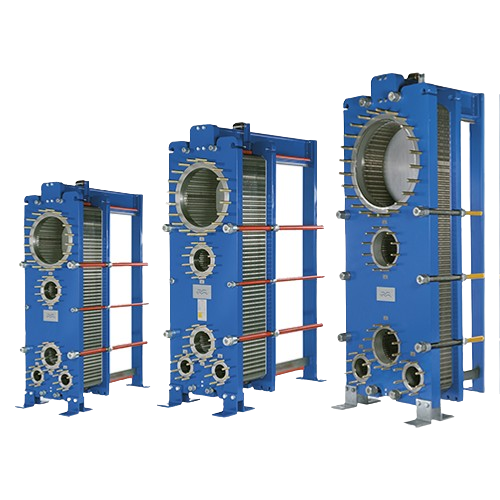

Plate surface condenser for vapour under vacuum

Experience high-efficiency condensation in space-constrained environments with the innovative design of this vacuum condenser, perfect for recovering condensates and reducing energy use in continuous production processes.

Condenses Vapors and Separates Non-Condensables

The AlfaCond Vacuum Plate Condenser from Alfa Laval revolutionizes the way vapors are condensed under vacuum conditions in bioethanol plants, sugar refineries, and small power plants. By utilizing a unique porthole configuration and asymmetric channel gaps, it minimizes pressure drops and maximizes heat transfer efficiency, handling a variety of vapors with precision. This condenser is compact yet capable of high throughput, fitting seamlessly into space-constrained environments. It integrates smoothly into your existing operations, removing non-condensable gases via an efficient vacuum system. AlfaCond’s design is optimized for energy efficiency and effective condensate recovery, offering optional subcooling to meet specific processing needs. Maintenance is simplified with a CIP system and robust gasket technology that ensures reliability under rigorous cleaning regimes. With options to configure materials for enhanced chemical compatibility, AlfaCond adapts to a diverse range of industrial applications while providing robust engineering support to tailor solutions to your operation’s requirements.

Benefits

- Optimizes space utilization in compact facilities with its compact design.

- Enhances production efficiency by minimizing pressure drops and maximizing heat transfer.

- Simplifies maintenance and reduces downtime with its Cleaning-in-Place system.

- Increases energy savings through efficient condensate recovery under vacuum.

- Adaptable to diverse applications with configurable material options for chemical compatibility.

- Applications

- Condensate recovery, Sugar, Bioethanol, Evaporation systems, Power plants

- End products

- Concentrated solution, Ethanol fuel, Purified condensate, Refined sugar, Electricity

- Steps before

- Vapour generation, Evaporation

- Steps after

- Condensate recovery, Non-condensable gas removal

- Input ingredients

- vapour, cooling water

- Output ingredients

- condensate, non-condensable gases, cooling water

- Market info

- Alfa Laval is renowned for its expertise in heat transfer, separation, and fluid handling technologies, providing innovative, energy-efficient engineered-to-order solutions for various industries including food, marine, and energy.

- Design Type

- Plate-and-frame heat exchanger

- Condensing Use

- Vapour under vacuum

- Compact Design

- Highly compact

- Cleaning Method

- CIP / Mechanical

- Configuration Options

- With or without subcooling

- Non-condensables Removal

- Condensate outlet pipe

- Porthole Configuration

- For vacuum condensation

- Channel Gap Size

- Asymmetric

- Pressure Drop

- Very low on vapour side

- Heat Transfer Efficiency

- Maximized

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP

- Cleaning method

- CIP / Mechanical

- Energy efficiency

- High / Compact design

- Changeover time

- Quick / Easy

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Discharge method

- Non-condensables removed from outlet pipe

- Shape and Size

- Plate design

- Condensation method

- Vapour condenses in welded channel

- Porthole configuration

- Unique for vacuum condensation

- Channel gap size

- Asymmetric, larger on vapour side

- Subcooling of condensate

- Optional

- Configuration Options

- With or without subcooling

- Size

- Compact

- Cleaning Method

- CIP or mechanical