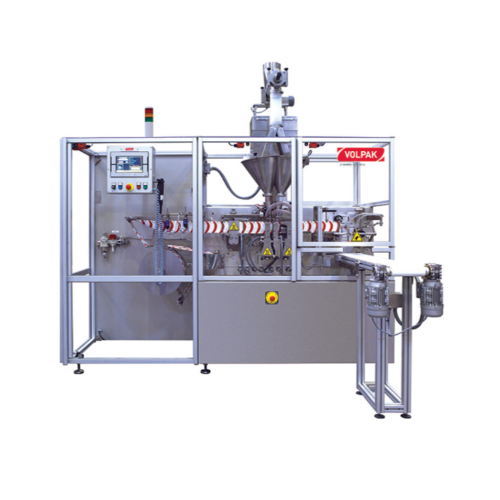

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-speed, continuous operation, ensuring seamless integration and improved efficiency in your packaging line.

Packages Liquids and Powders into Flat Pouches

The SL 110 from Volpak is designed for high-speed horizontal flat pouching, catering to food, beverage, and chemical industries. This machine excels by delivering up to 180 pouches per minute, effectively handling both liquid and powder products. It integrates seamlessly into production lines via its continuous operation, utilizing advanced PLC control for precise pouch dimensions. Energy efficiency is heightened by optimized motor performance, saving up to 30% in consumption compared to standard models. Constructed from durable materials, it offers resistance to a range of chemicals. The SL 110 supports custom configurations and provides convenient maintenance with its simple-access design, ensuring minimal downtime.

Benefits

- Enhances productivity with speeds of up to 180 pouches per minute.

- Minimizes energy costs with motor optimization, reducing consumption by 30%.

- Easy integration into existing lines with continuous, automated operation.

- Versatile application handling for both liquid and powder products.

- Robust construction ensures longevity and resistance to various chemicals.

- Applications

- Biscuits, Sauces, Snacks, Fats, Oils, Other home care, Chocolate, Soft drinks, Rtds, Laundry care, Other tea, Condiments, Candies, Spices, Other chemicals, Tea, Powdered milk, Spreads, Sugar, Other food, Baby food, Salt, Baked goods, Coffee, Gums, Cereals, Crackers, Dishwashing, Lubricants

- End products

- Engine oil, Potato chips, Green tea leaves, Nut butter, Carbonated cola drinks, Skimmed milk powder, Chocolate chip cookies, Pre-mixed iced tea, Chewing gum, Olive oil, Espresso coffee, Cornflakes, Matcha powder, Granulated sugar, Pancake mix, Himalayan pink salt, Butter, Cheese crackers, Fabric softener, Milk chocolate bars, Instant noodles, Gummy bears, Baby formula, Industrial cleaners, Dishwashing liquid, Mayonnaise, Ground black pepper, Tomato ketchup

- Steps before

- Mixing, Ingredient Preparation, Formulation, Blending

- Steps after

- Packing, Labeling, Sealing, Quality Control

- Input ingredients

- flat pouches, up to 60ml capacity, baby food ingredients, baked goods mixtures, biscuit and cracker doughs, candies ingredients, gum bases, cereals components, chocolate mixtures, salt varieties, sugar, spices, oils, fats, sauces, condiments, snack bases, spread ingredients, soft drinks components, ready-to-drink (RTD) mixes, powdered milk, dishwashing fluids, laundry care substances, lubricants, coffee grounds, tea leaves

- Output ingredients

- pouched baby food, baked goods in pouches, biscuits and crackers in pouches, candies in pouches, gum in pouches, cereals in pouches, chocolate in pouches, salt in pouches, sugar in pouches, spices in pouches, oils in pouches, fats in pouches, sauces in pouches, condiments in pouches, snacks in pouches, spreads in pouches, soft drinks in pouches, RTDs in pouches, powdered milk in pouches, home care products in pouches, dishwashing products in pouches, laundry care products in pouches, lubricants in pouches, coffee in pouches, tea in pouches

- Market info

- Volpak (Coesia Group) is known for its expertise in designing and manufacturing horizontal form-fill-seal machines, specializing in flexible packaging solutions for the food, beverage, and personal care industries, with a reputation for innovation and efficiency.

- Pouch type

- Flat

- Pouch capacity

- Up to 60 ml

- Speed

- Up to 180 ppm

- Technology

- Horizontal Flat Pouching

- Working mechanism

- Horizontal Flat Pouching

- Speed

- Up to 180 ppm

- Pouch Volume

- Up to 60 ml

- Industry Application

- Food, Beverage, Dairy, Home Care, Chemicals, Tea, Coffee

- Segment Compatibility

- Baby Food, Snacks, Soft Drinks, Sauces, Oils, etc.

- Automation Level

- Integration with FlexLink Conveyor Systems

- Abrasion resistance

- Yes

- Biological compatibility

- Food grade

- Cleanability

- CIP compatible

- Corrosive resistance (e.g. acids)

- High

- Density/particle size

- Variable compatible

- Pouch size capacity

- up to 60ml

- Control panel type

- HMI / PLC interface

- Integration Possibilities

- Compatible with FlexLink X85

- Discharge method

- Horizontal discharge for flat pouches

- Compact footprint

- Space-saving design

- Bag type

- Flat Pouches