Continuous vacuum conveyors for material flow control

Ensure consistent material transfer and reduce downtime in your production line with advanced continuous vacuum conveyors, designed to seamlessly handle powders, granulates, and even adhesive materials with minimal residue, optimizing your conveying and separation processes.

Conveys and Separates Powders, Granulates, and Liquids

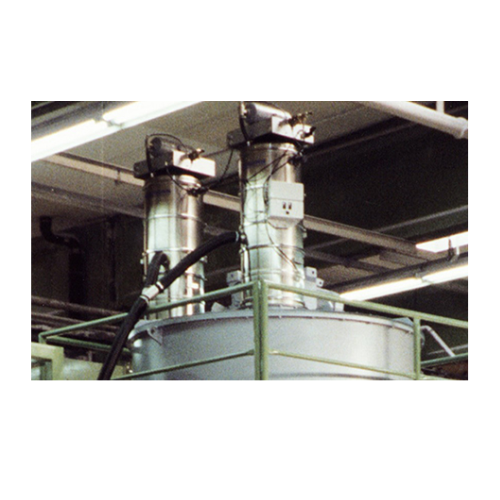

The Continuous Vacuum Conveyor System CC from Volkmann is engineered to maintain uninterrupted material flow for demanding pharmaceutical, chemical, and food industries. Key features include a robust Volkmann vacuum pump/filter setup, which operates continuously while enabling reverse jet filter cleaning through a sequential switch-off mechanism. This ensures s efficient material conveyance and separation with minimal delay.

Capable of handling a diverse range of materials including powders, granulates, liquids, and adhesive substances, the system is ideally suited for applications such as pharmaceutical powder transfer, chemical granule separation, and food product processing. The system offers a conveying rate between 1 to 500 kg/h and features quick-to-dismantle components made from stainless steel 316L or other FDA-approved materials, facilitating easy cleaning and maintenance.

Integration into existing production lines is seamless, with ATEX-approved rotary valves and pneumatic piston vibrators minimizing product residue and ensuring compliance with stringent hygienic standards. The equipment supports continuous operations and is configurationally flexible, making it an excellent choice for manufacturers needing tailored material handling solutions that enhance processing efficiency and compliance.

Benefits

- Ensures continuous material flow, minimizing production interruptions and enhancing operational efficiency.

- Reduces labor-intensive cleaning with easily dismantable and hygienic design components.

- Lowers risk of contamination with stainless steel 316L and FDA-approved material construction.

- Integrates seamlessly with existing production lines due to its flexible, modular design.

- Complies with ATEX standards, providing safety in explosive or hazardous environments.

- Applications

- Wet materials, Food industry, Chemical industry, Adhesive materials, Additive manufacturing, Granulate, Powder, Tablets, Pharmaceutical industry, Liquids

- End products

- Cosmetic powders, Chemical liquids, Sugar granules, Pharmaceutical syrups, Sticky resins, Milk powder, Protein powder, 3d printing materials, Pharmaceutical powders, Chemical granules

- Steps before

- Purification, Drying, Grinding, Mixing, Pre-weighing

- Steps after

- Sterilization, Packing, Weighing, Filling, Tablet Pressing

- Input ingredients

- powder, granulate, wet materials, product suspended in liquids, adhesive material

- Output ingredients

- separated material, discharged material

- Market info

- Volkmann is known for manufacturing vacuum conveying systems, specializing in pneumatic conveying of bulk materials. Their reputation for innovative and reliable equipment solutions in various industries positions them as a trusted provider for engineered-to-order material handling systems.

- Conveying rate

- 1 – 500 kg/h

- Separator diameter

- 200 – 350 mm

- Rotary valve diameter

- 100 or 150 mm

- Material of construction

- Stainless steel 316L / FDA-approved materials

- Cleaning method

- Easy to dismantle and clean

- Automation

- Continuous operation with sequential filter cleaning

- ATEX Compliance

- ATEX approved rotary valve

- Pneumatic assistance

- Pneumatic piston vibrator for handling adhesive material

- Continuous operation

- Yes

- Aspiration and material flow

- Continuous

- Automation level

- PLC

- Integrated reverse jet filter cleaning

- Yes

- Easy dismantling for cleaning

- Manual

- Material evacuation

- Pneumatic piston vibrator

- Batch vs. continuous operation

- Continuous

- Cleanability

- Stainless steel 316L / FDA-approved materials

- Corrosive resistance (e.g. acids)

- Stainless steel 316L

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- ATEX certification

- Yes

- FDA compliance

- Yes

- FDA materials

- 316L stainless steel / FDA-approved materials

- CE marking

- Yes

- Separator Diameter

- 200–350 mm

- Rotary Valve Diameter

- 100 or 150 mm

- Material Composition

- Stainless Steel 316L / FDA-approved

- Disassembly

- Tool-free, by hand

- Footprint

- Compact design

- Cleaning Accessibility

- Easy to clean

- Discharge method

- Rotary valve / Pneumatic piston vibrator

- Material Compatibility

- Stainless steel 316L / FDA-approved materials

- Separator diameter

- 200–350 mm

- Rotary valve diameter

- 100 mm / 150 mm

- Easy dismantling

- By hand