Butterfly valves for powder and granular material handling

Experience seamless material control with advanced butterfly valves, designed to efficiently intercept and discharge powders and granules in continuous and manual operations, ensuring consistent flow and optimal process integration.

Controls and Intercepts Material Flow

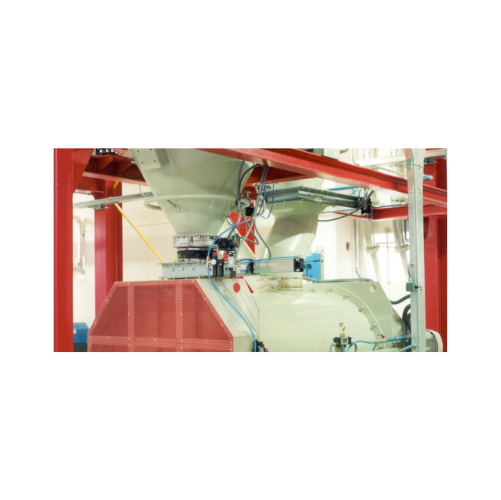

The Butterfly Valves VFS from WAMGROUP offer reliable interception and discharge solutions for powdery and granular materials in various industries. These valves are constructed with high-pressure aluminum alloy die-cast semi-bodies and feature a SINT polymer composite or stainless-steel disc, ensuring durability and corrosion resistance. They are essential for processes requiring material flow control, such as construction, feed, food, plastics, and chemicals industries. The VFS valves handle the interception of gravity-fed or pneumatically conveyed materials effortlessly, accommodating a range of operations from continuous to high-speed. Designed for integration, they fit beneath hoppers, bins, silos, and conveyors, and are compatible with upstream and downstream processes in your production line. Additionally, their dust-tight and pressure-proof design up to 0.2 bar ensures operational efficiency and safety. Enjoy low maintenance costs and easy disc interchangeability, with options for food-grade applications to meet industry standards.

Benefits

- Enhances material processing efficiency with precise flow control.

- Minimizes maintenance downtime with easy-to-replace components.

- Provides seamless integration with existing hoppers, bins, and conveyors.

- Reduces operational costs due to durable, abrasion-resistant design.

- Offers flexibility for various applications with interchangeable discs and material options.

- Applications

- Lime, Cosmetics, Soap, Drymix building materials, Minerals, Chocolate, Cement, Granular materials, Rubber, Resin, Cocoa, Animal feed, Pasta, Sugar, Varnish, Biscuit, Fertilizer, Rice, Plastics, Salt, Pharmaceuticals, Paint, Coffee, Flour, Detergent, Gypsum, Powdery materials, Breweries

- End products

- Steps before

- Grinding, Mixing, Bulk Solids Conveying, Pneumatic Conveying

- Steps after

- Packing, Dust Filtration, Bulk Solids Loading, Silo Safety Monitoring

- Input ingredients

- powders, granules, dry materials, gravity-fed materials, pneumatically conveyed materials

- Output ingredients

- intercepted materials, regulated material flow

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Pressure

- Up to 0.2 bar (2.9 PSI)

- Material

- Aluminium alloy, SINT polymer, Cast iron, Stainless steel

- Seal Type

- Elastomer seal, FDA/EN-approved

- Flange Type

- Top flange (V1FS), Identical top and bottom flange (V2FS)

- Abrasion Resistance

- High

- Disc Materials

- Cast Iron, SINT engineering polymer, Stainless steel

- Application

- Powders, Granules

- Weight

- Lightweight

- Assembly

- Easy to handle

- Delivery Time

- Ex-stock

- Certification

- ATEX-certified

- Compliance

- EN 1935/2004 standards

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Abrasion resistance

- Yes

- Cleanability

- Yes

- Corrosive resistance

- Yes, stainless steel version available

- Density/particle size

- Applicable to powders, granules

- Discharge method

- Gravity-fed / Pneumatic conveying

- Disc material

- Cast iron / SINT polymer / Stainless steel

- Seal type

- Elastomer (standard or food-grade)

- Valve construction

- High-pressure aluminum alloy die-cast semi-bodies

- Size Options

- V1FS with top flange

- V2FS with identical flanges

- Disc material

- Cast iron / SINT polymer / Stainless steel

- Seal material

- Pre-stressed elastomer / FDA/EN-approved integral seal

- Configuration type

- Flexible sleeve attachment / Duct interception