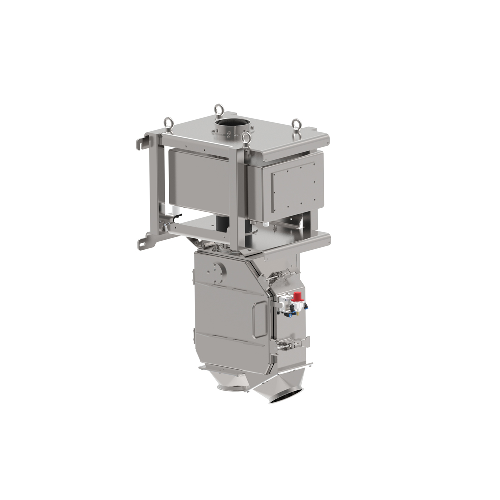

Metal detection system for powders & granules

Ensure product integrity and protect your machinery from metallic contaminants with advanced detection technology, designed to seamlessly integrate into existing production lines for efficient and precise monitoring of powdered goods and granulates.

Detects and Removes Metal Contaminants

The RAPID PRO-SENSE 6 from Sesotec sets a new standard in metal detection for free-fall applications across food, plastics, and chemical industries. It features innovative high-resolution frequency (HRF) technology, ensuring unparalleled detection sensitivity for both ferrous and non-ferrous metals, including non-magnetic stainless steel. Ideal for powdered foods and plastic granules, this equipment is designed to integrate seamlessly into continuous, high-speed processing lines. Its modular design allows easy customization, quick integration due to low installation height, and flexible configuration of reject mechanisms for specific materials. With a robust stainless steel construction, automatic learning for material conductivity, and easy-to-use GENIUS+ control interface, it allows for straightforward installation and maintenance. The system meets IFS, BRC, and FSMA standards, and is UL and CSA certified for North American markets, offering reliable compliance and operational safety.

Benefits

- Enhances product safety by efficiently detecting and removing metal contaminants.

- Reduces operational costs with quick setup and easy integration.

- Lowers maintenance demands through a modular design and auto-cleaning options.

- Increases production efficiency with high-speed, continuous operation capability.

- Ensures regulatory compliance, meeting IFS, BRC, and FSMA standards.

- Applications

- Powdered milk, Foil chips, Sugar, Wood pellets, Noodles, Chemical additives, Powdered foods, Herbs, Flour, Granola, Crisps, Salt, Tea, Plastic granulate, Fibres

- End products

- Brown sugar, Oat clusters, Baking powder, Cotton fibers, Pasta shells, Pvc granules, Infant formula, Sea salt, Wood briquettes, Bread flour, Potato chips, Green tea leaves, Aluminum foil scraps, Food preservatives, Dried basil

- Steps before

- Grinding, Drying, Ingredient Mixing, Pre-cleaning

- Steps after

- Quality Assurance, Packing, Sorting, Recycling

- Input ingredients

- plastic granulate, powdered foods, sugar, salt, chemical additives, herbs, tea, fibres, wood pellets, foil chips, granola, noodles, crisps, powdered milk, flour

- Output ingredients

- contaminant-free plastic granulate, contaminant-free powdered foods, contaminant-free sugar, contaminant-free salt, contaminant-free chemical additives, contaminant-free herbs, contaminant-free tea, contaminant-free fibres, contaminant-free wood pellets, contaminant-free foil chips, contaminant-free granola, contaminant-free noodles, contaminant-free crisps, contaminant-free powdered milk, contaminant-free flour

- Market info

- Sesotec is known for specializing in the development and manufacturing of innovative machine technology, particularly for metal detection, sorting, and separation systems used across industries such as food, plastics, and recycling, ensuring product quality and safety.

- Detection accuracy

- High scanning sensitivity for all metals

- Scanning sensitivity

- High-resolution frequency (HRF) technology

- Automation

- Auto-learn function

- Material integration

- Easy integration into existing piping systems

- Installation height

- Low installation height

- Contaminant removal

- Automatic reject mechanisms

- Control units

- GENIUS+ and PRIMUS+ with graphic LCD displays

- Metal parts

- Stainless steel 1.4301 (AISI 304)

- Certification

- UL and CSA certification

- Product compensation

- Auto-learn function

- Control system

- Modular machine design

- Reject mechanisms

- Different mechanisms based on material properties

- Signal processing

- Digital signal processing and quartz-stabilised detection frequency

- Multi-product memory

- Up to 240 products

- Self-monitoring

- Yes

- Working Mechanism

- Free-fall

- Scanning Sensitivity

- Highest for all metals

- Integration

- Easy to integrate into existing piping

- Reject Mechanism

- Automatic removal based on material properties

- Auto-learn Function

- Compensates intrinsic conductivity

- Installation Height

- Low, even with large nominal widths

- Control System

- GENIUS+ / PRIMUS+ with graphic LCD

- Material Contact

- Stainless steel 1.4301 (AISI 304)

- Certification

- UL / CSA for North American market

- Customization

- Modular machine design

- Self-monitoring

- Visual and acoustic signalling

- Abrasion resistance

- Yes

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Stainless steel 1.4301 (AISI 304)

- Biological compatibility

- Food-grade

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Low installation height

- Discharge method

- Free-fall

- Control panel type

- GENIUS+ and PRIMUS+ with graphic LCD displays

- Construction material

- Stainless steel 1.4301 (AISI 304)

- Control panel type

- GENIUS+ / PRIMUS+

- Integration possibilities

- Existing piping systems

- Modular design

- Adjustable free-fall height and contamination outlet position

- Reject mechanisms

- Standard, Round, Hopper-shaped