Fruit Juice Processing Equipment And Production

Find innovative production technology for making fruit juice and connect directly with world-leading specialists

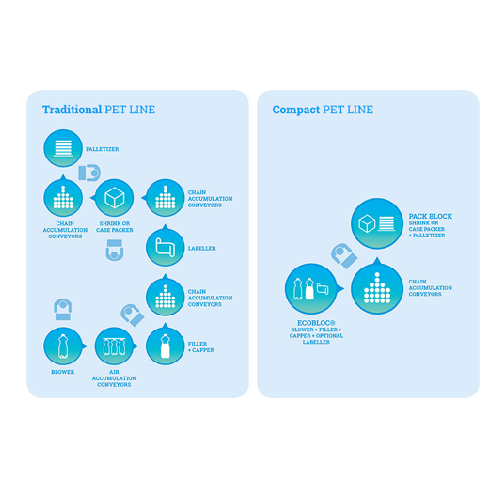

Pineapples, oranges, passion fruit, you name it. A fruit juice process begins with selecting and cleaning the raw material of your choice and goes through steps like extraction and a filtration machine until it reaches market shelves in bottles. Juice processing equipment varies according to the amount of water in the fruit.

Select your fruit juice process

Tell us about your production challenge

Starting your fruit juice production process: cleaning and extraction

The first procedure is to wash the fruits. To do this, you can choose from options like a surfing washing machine, which tumbles and clean fruits with high-press water pumps; a brushing and spraying cleaning machine, in which both processes happen at the same time; or a fruit bubble washing machine, where you drown the fruits in water and soap.

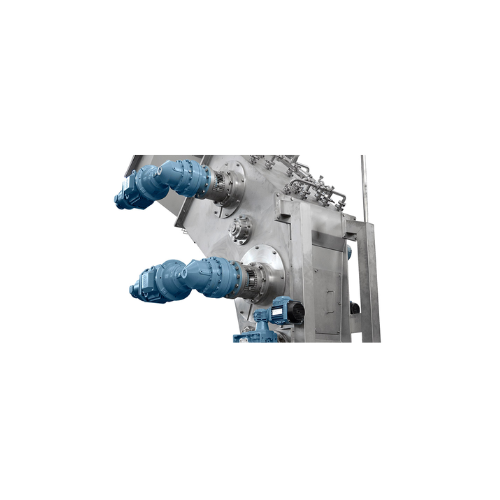

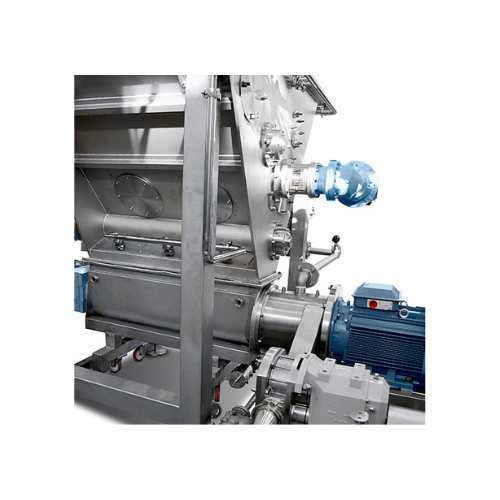

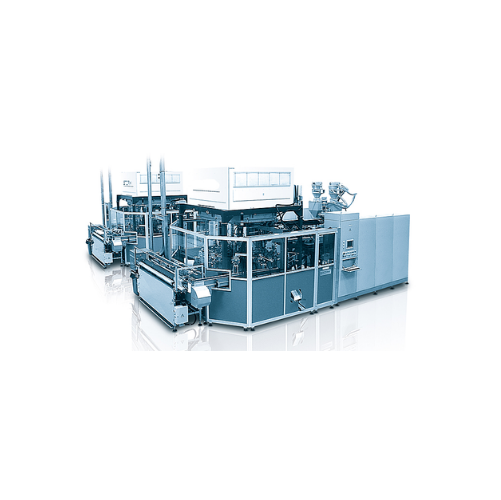

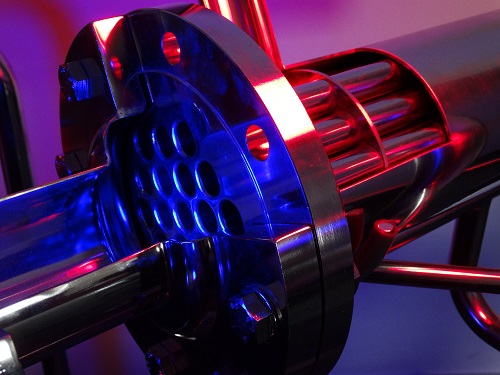

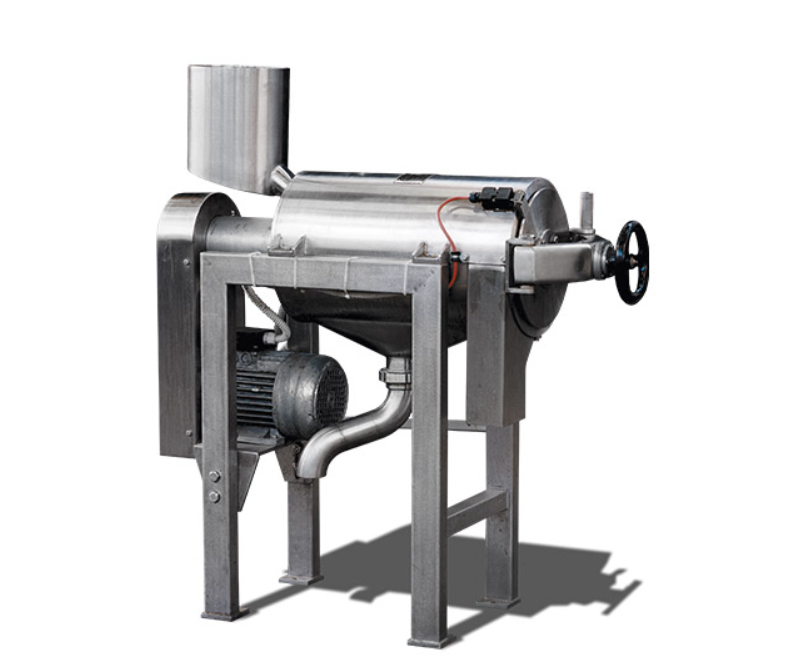

After cleaning, you need to extract the juice from the fruit. Extraction highly depends on the kind of fruit you choose, and some fruits need preparation before juice extraction. Fruits with more water content usually go through a presser line, which can conduct cold, hot and freeze pressing depending on the raw material’s temperature. Dryer fruits go through solvent extraction, where you put the juice from fruits cells in a hot water extract. Extraction can also happen with centrifuge equipment. In this case, the centrifugal force from the machine separates the juice from the flesh. Another way to extract juice is to put the fruits under enzymatic treatment. This is more common in processing plants.

Filtration, clarification and mixing of fruit juices

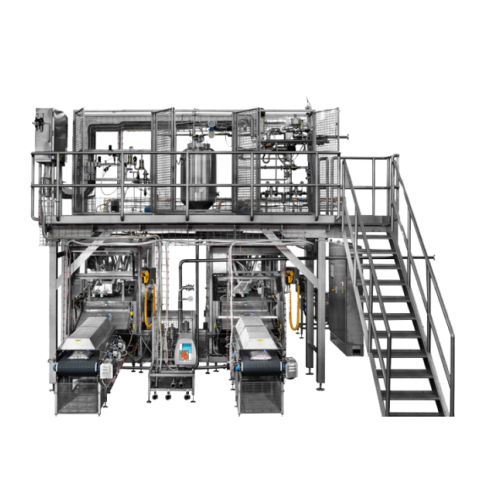

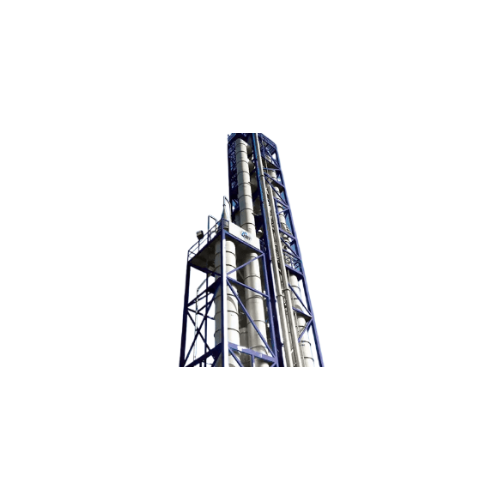

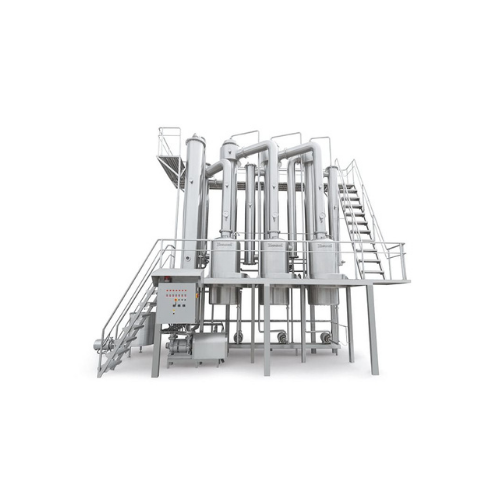

If you are making clear juice, after clarifying it to remove pectin and other carbohydrates, you need a filtration equipment system to continue the production and remove solids. In case you are producing cloudy juice, the next steps may also be filtration or centrifugation, so insoluble particles can be left out. Concentrated juices go through evaporation to remove water; they need to be reconstituted afterward to regain the flavors lost in the process.

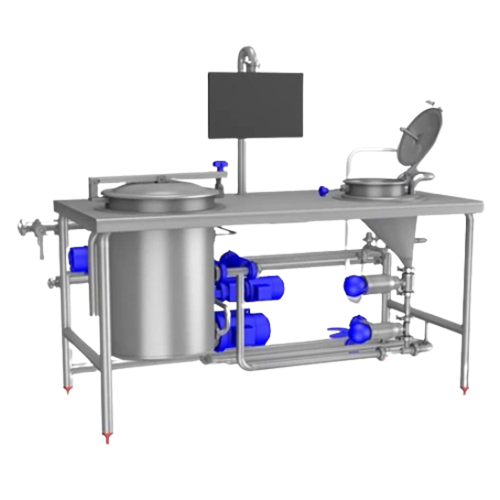

Fruit juice manufacturing methods can differ greatly depending on the type of juice you are making. And also, the type of machine that is being used. Whether it is for reconstitution of fruit concentrate or to mix other ingredients and reach a homogenized texture, juice mixing tanks can help reach an even mixture with the right dose of ingredients.

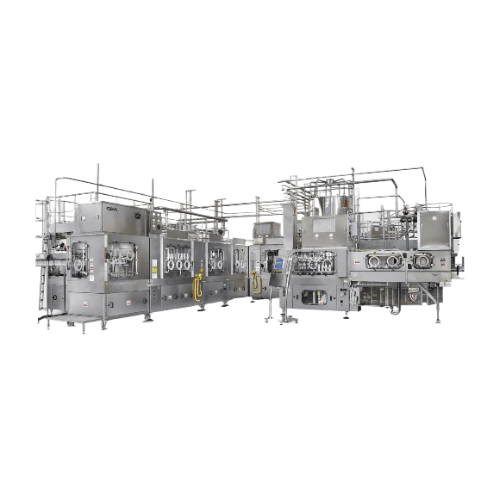

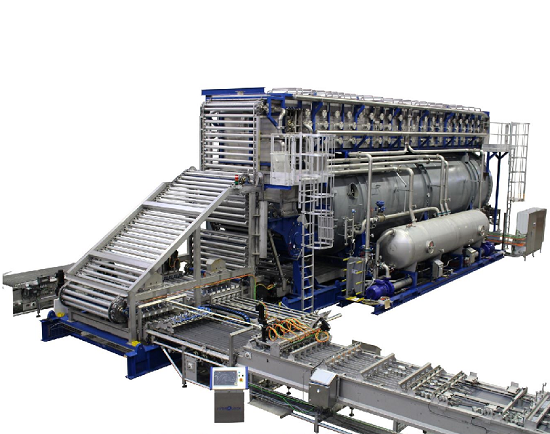

Finishing fruit juice production: pasteurization, bottling and packing

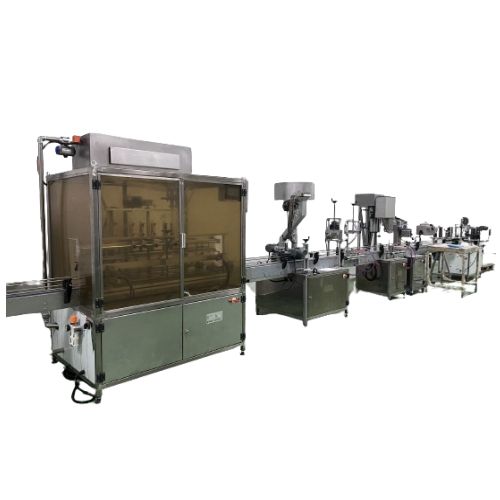

After mixing, but before filling the bottles, you need to pasteurize your fruit juice. This kills microorganisms and deactivates enzymes that can make your juice more turbid than you want it to be. Pasteurization also provides more safety for fruit juice consumption and extends its expiration date. It can also improve the quality of the end product.

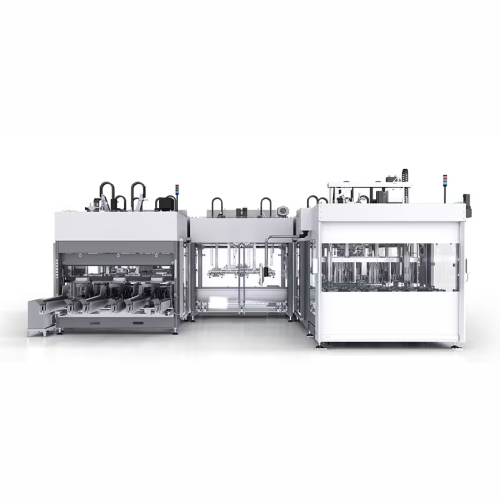

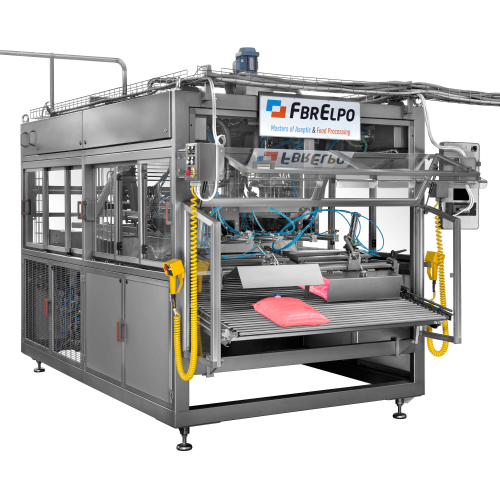

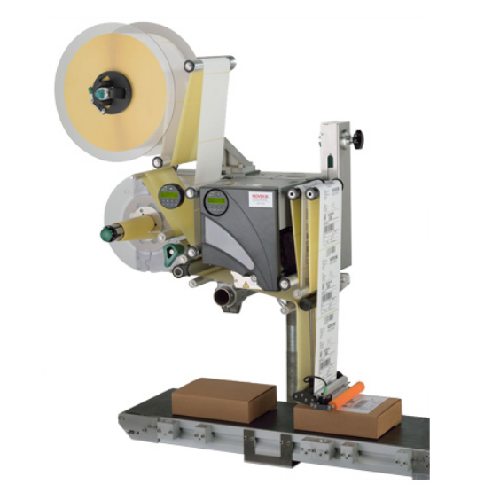

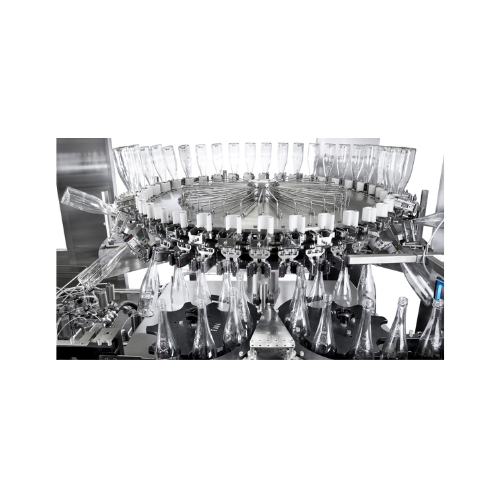

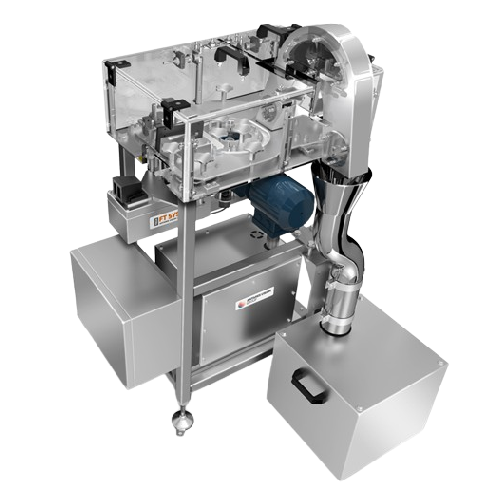

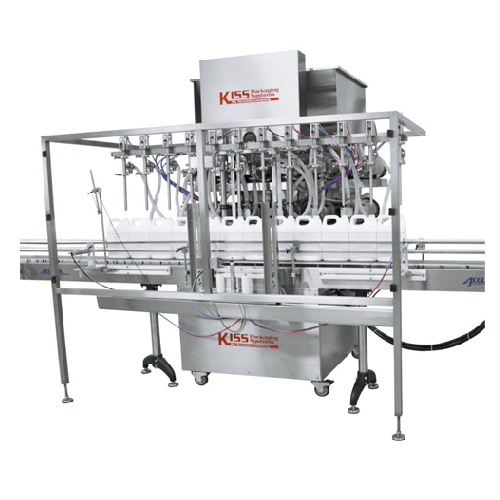

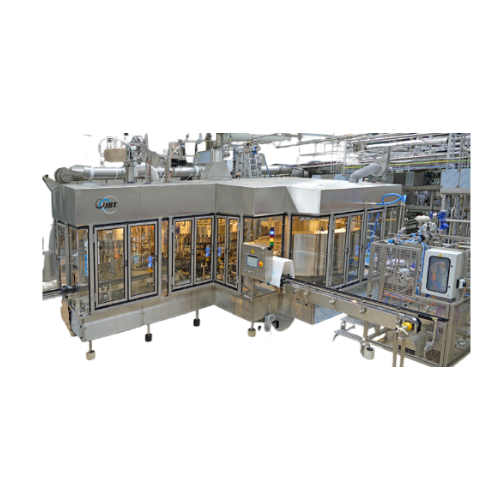

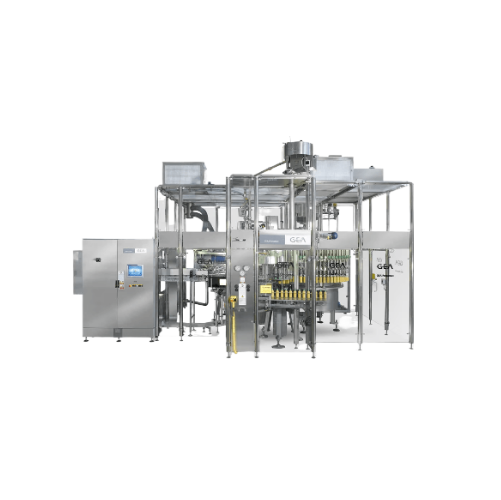

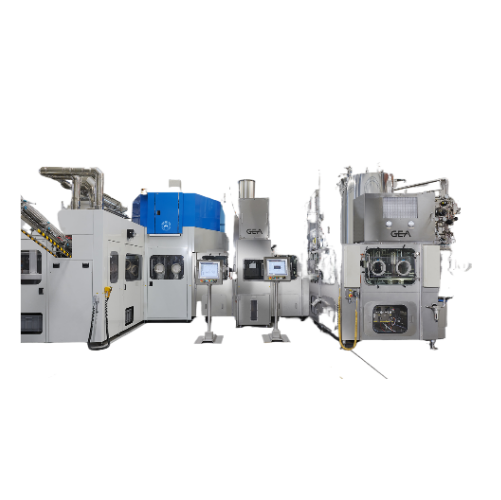

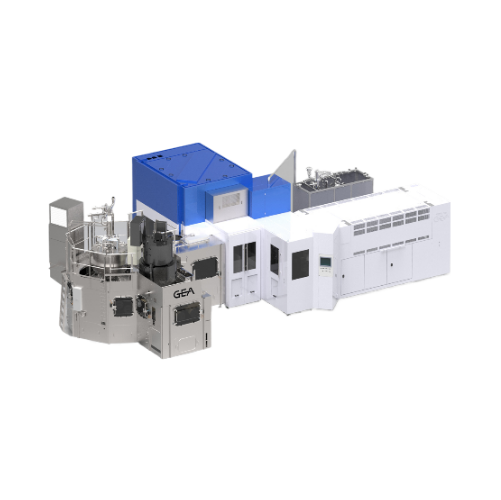

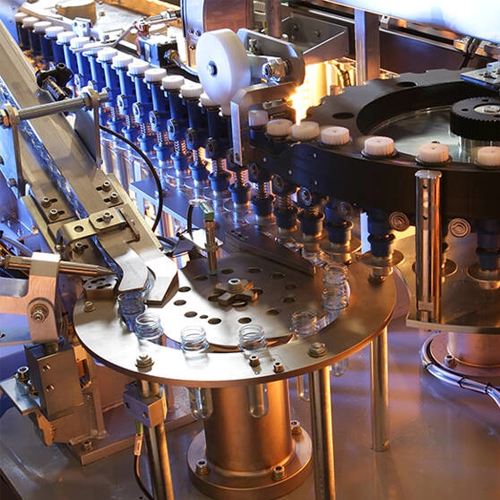

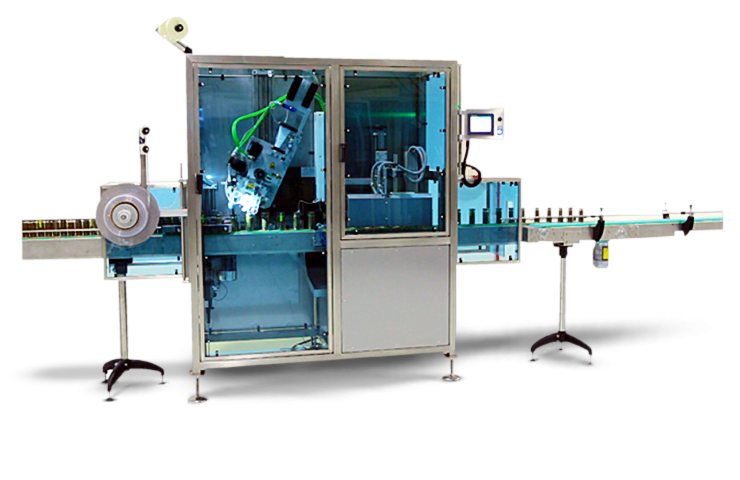

A filling system machine will bottle and cap your fruit juice. Using equipment like this requires low human control. You can regulate the amount of liquid in the bottle and the speed of filling, to avoid wasting juice. The last steps are labeling and packing your fruit juice. This is generally a separate manufacturing line in a processing plant. And will require special labeling and packing equipment.

Processing steps involved in fruit juice making

Which fruit juice technology do you need?

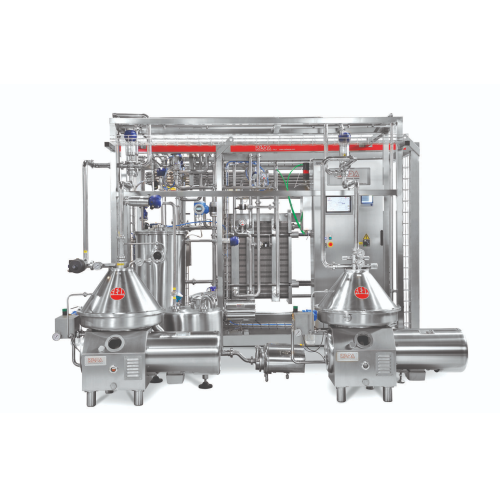

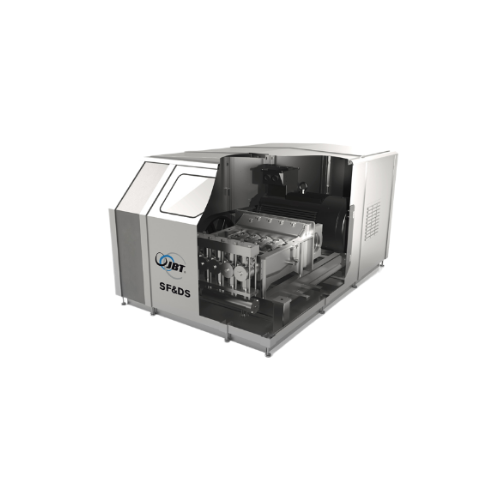

Citrus juice de-oiling separator

Achieve optimal citrus juice clarity and essential oil separation with this advanced three-...

Clarifiers for biochemical separation

Achieve seamless liquid-solid separation with high-speed disk-type clarifiers, ensuri...

Clarifier for beverages

Enhance beverage clarity and purity with high-performance centrifugal separation, expertly designed t...

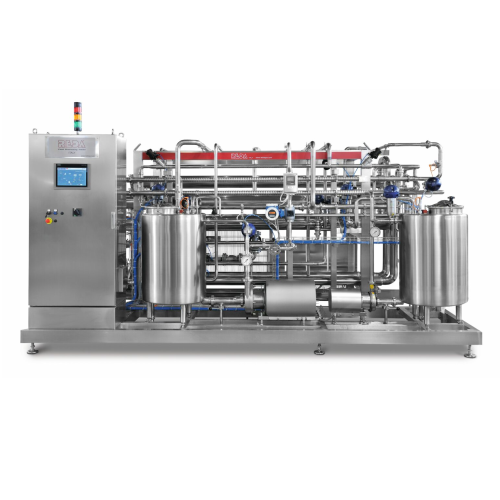

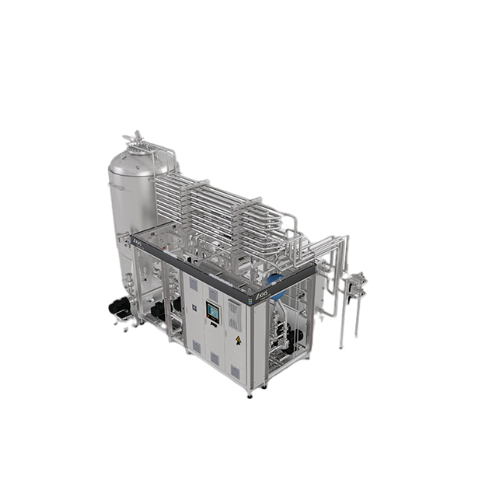

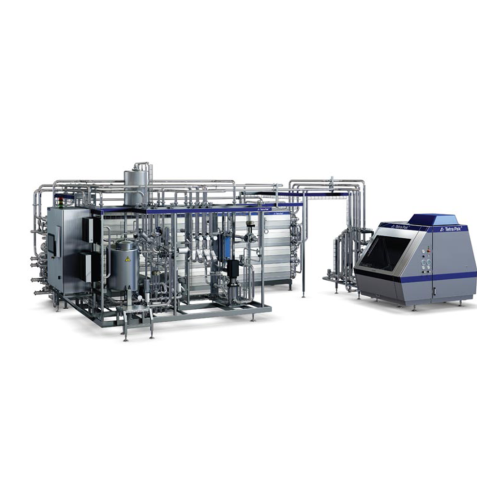

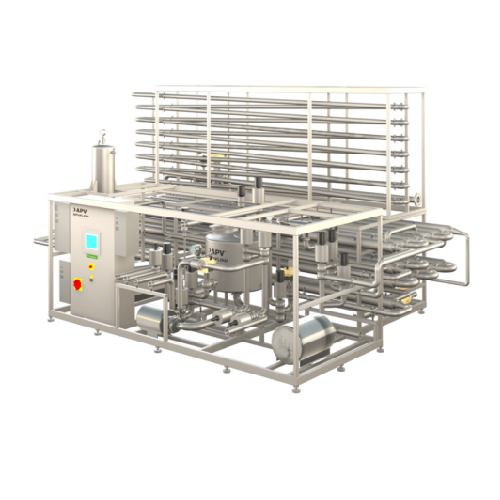

Uht sterilization for drinkable milk

Ensure long shelf-life and food safety without compromising the natural qualities of y...

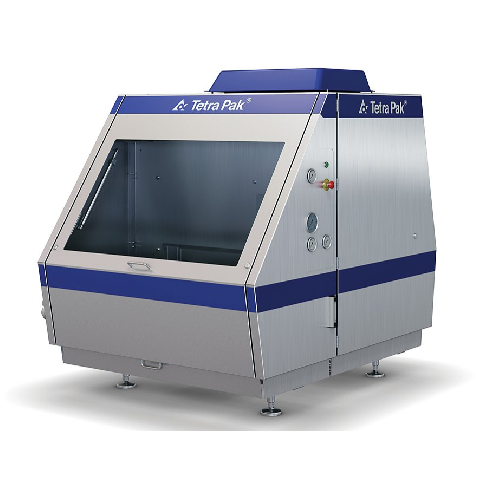

Pasteurizer for extended shelf-life (esl) milk

Extend the shelf life of milk while maintaining its taste and nutritional i...

Wine clarification system

Enhance your wine production by effectively removing unwanted solids and reducing oxidation risk, ...

Milk pasteurizer for whey and cream

Ensure optimal product safety and quality with advanced heat exchange technology, reduc...

Whey processing line

Streamline whey processing by transforming byproducts into high-value proteins, catering to diverse nutr...

Milk collection system for bulk tankers

Optimize milk transfer and storage with a reliable system that reduces discharge ti...

Milk skimming separators for dairy applications

Enhance dairy production with high-efficiency skimming separators that opt...

Milk standardization system

Achieve precise milk and cream fat standardization with this advanced inline system, optimizing ...

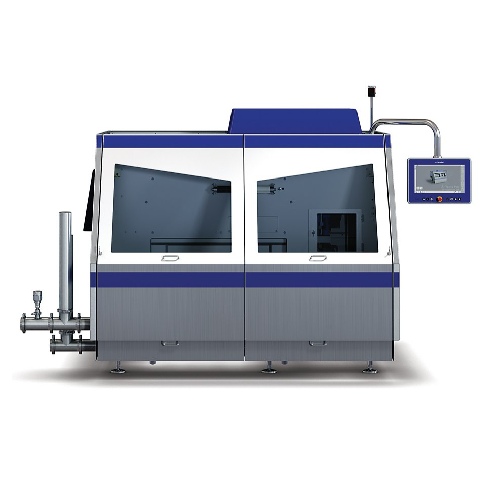

Pasteurizer for fresh milk

Ensure your dairy and beverage lines achieve optimal product safety and quality by leveraging adv...

Grape must concentration solution

Optimize the alcohol content and flavor profile of your wines by efficiently concentratin...

Membrane filtration for whey concentration

Enhance your liquid processing with advanced membrane filtration designed to im...

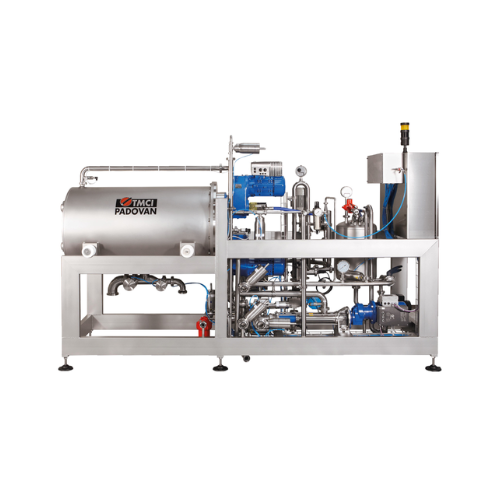

Blending and mixing unit for dairy and beverages

Achieve precise recipe control and high-quality results by seamlessly int...

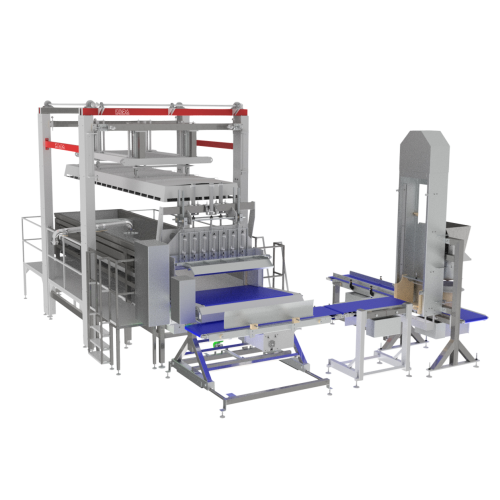

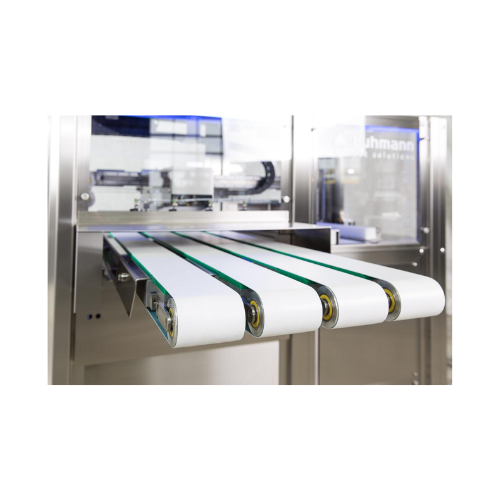

Cheese forming units for hard and semi-hard cheeses

Optimize your cheese production process with advanced moulding and pr...

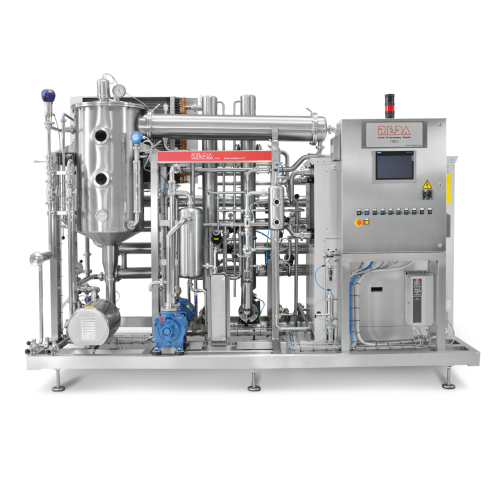

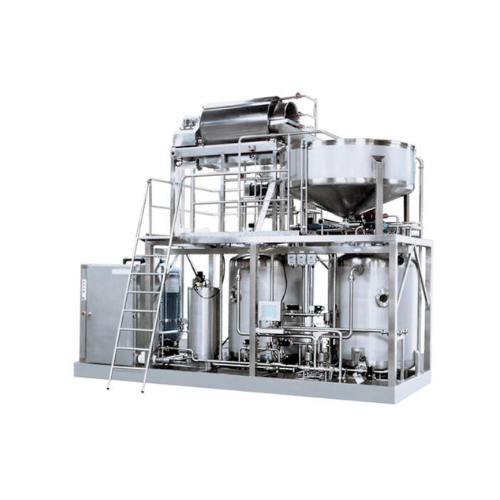

Low temperature evaporator for heat-sensitive food products

Efficiently concentrate sensitive liquid products while pres...

Wine dealcoholization system for low-alcohol wines

Struggling to meet market demands for low-alcohol wines? Achieve preci...

Milk evaporator for dairy industry

Optimize your liquid food production with precise control over evaporation processes, en...

Vacuum deaeration with aroma recovery for juices

Eliminate oxygen from liquid foods to prevent oxidation while retaining v...

Fermentation tank for yoghurt and fermented dairy products

Optimize your dairy and plant-based drink production with eff...

Bacteria removal separator for dairy products

Ensure top-quality dairy and plant-based products with reliable bacteria rem...

Brine purification system for reducing bacteria and molds

Ensure pristine brine quality by continuously removing bacteri...

Clarifier for milk and whey

Optimize dairy and beverage production by efficiently removing fine curd residuals, ensuring hig...

Juice clarification system

Ensure consistent beverage clarity with advanced separation technologies, enhancing production ef...

Curd making equipment for cheese production

Optimize your cheese production with versatile curd making equipment, designed...

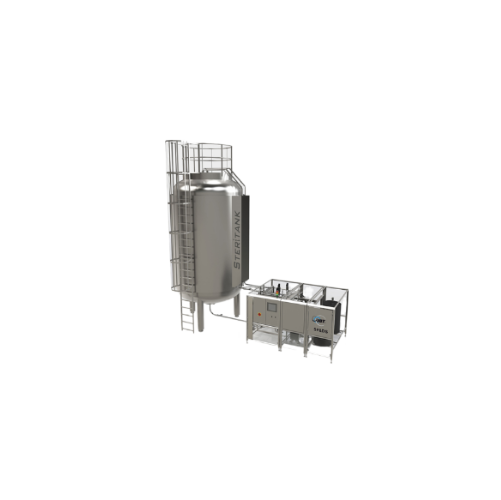

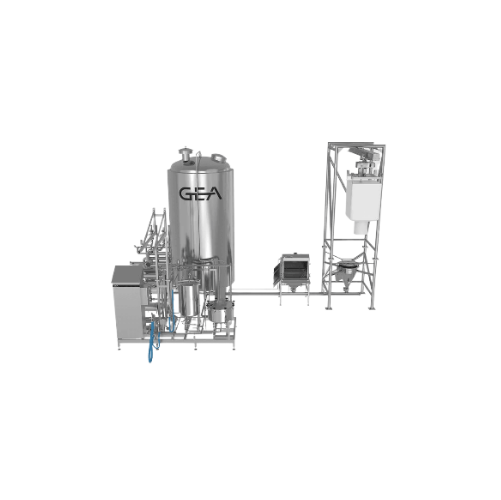

Aseptic tank for sterile liquid food storage

Ensure sterility and maximize shelf life for liquid foods by utilizing an ase...

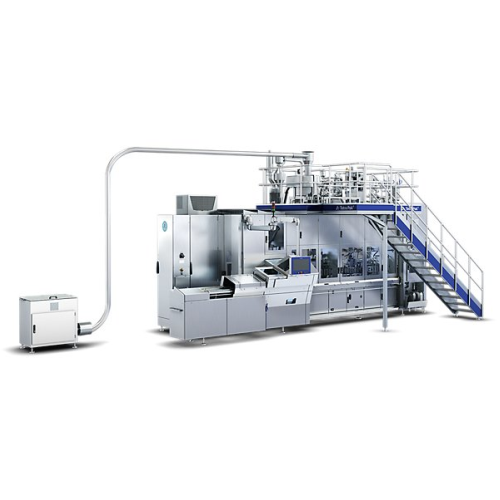

Uht sterilization for milk

Enhance your production line with advanced UHT sterilization, ensuring extended shelf-life and un...

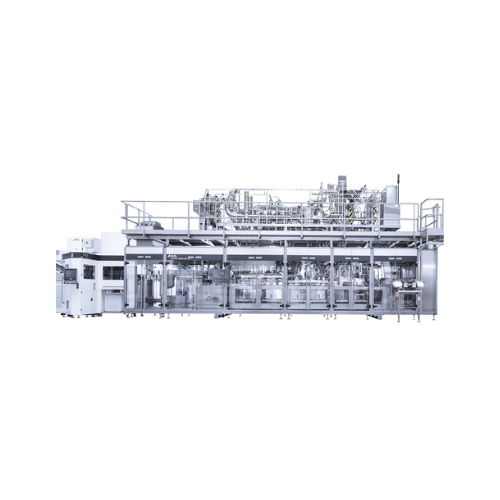

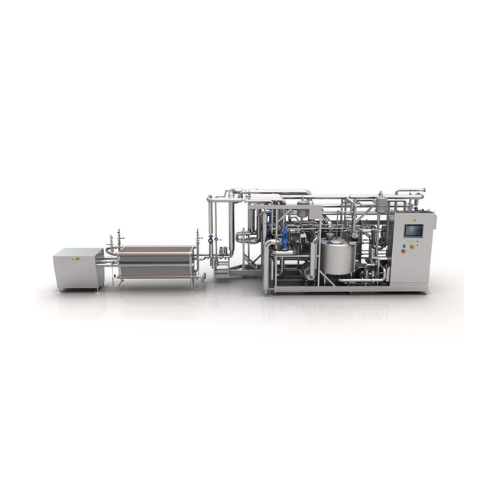

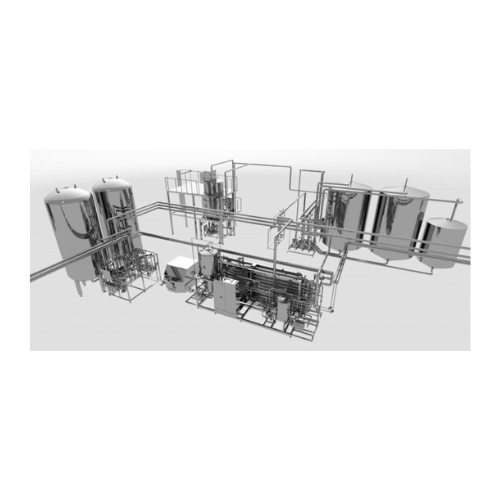

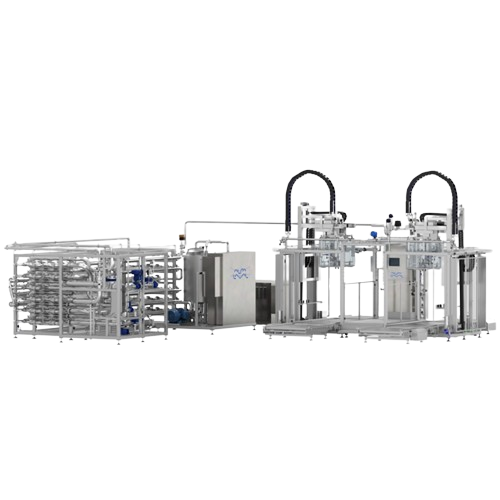

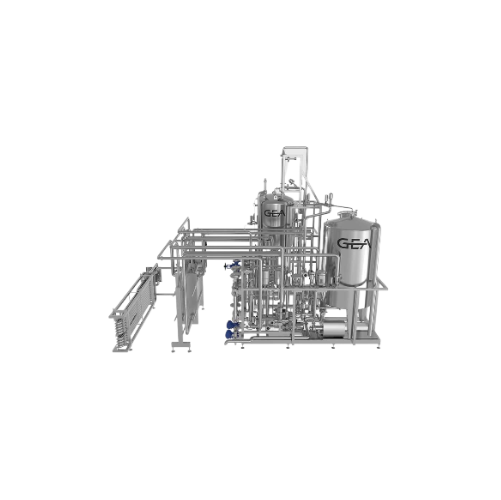

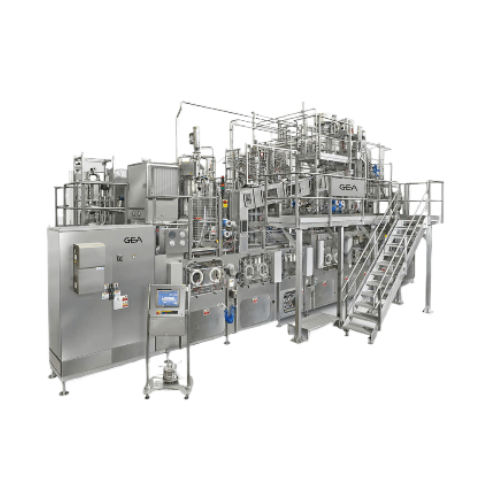

Complete milk processing lines

Optimize liquid product quality with a comprehensive processing line that integrates pasteuri...

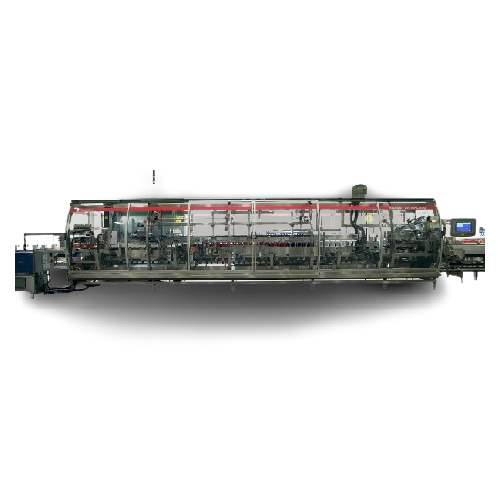

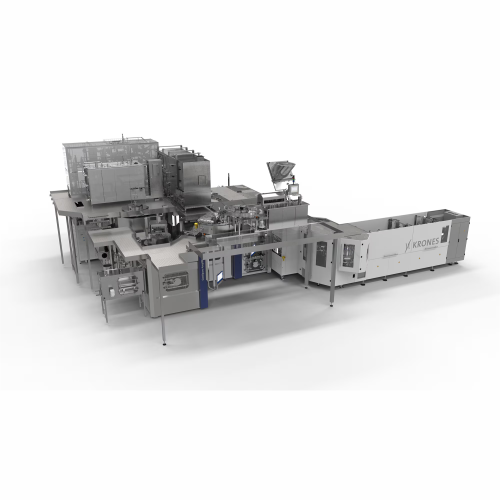

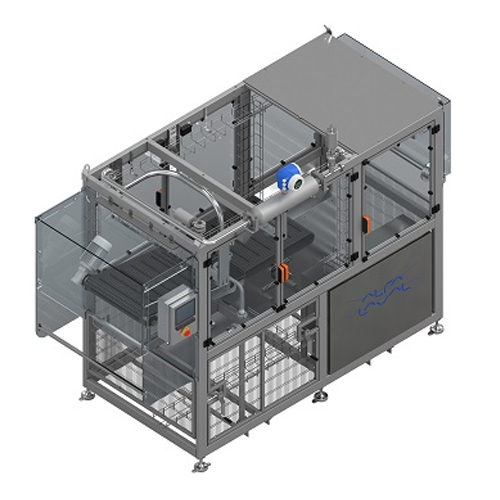

Beverage multi-pack cartoner for cans and bottles

Optimize your beverage production line with high-speed, continuous mult...

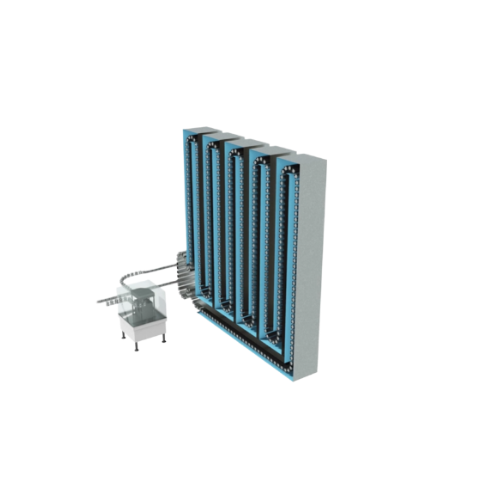

Pulsed electric field system for food preservation

Enhance your production line with technology that extends shelf life a...

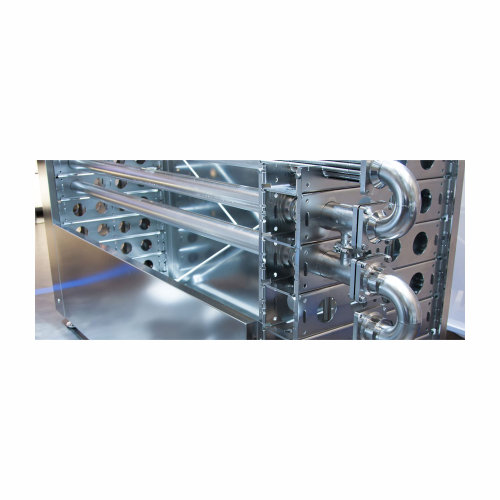

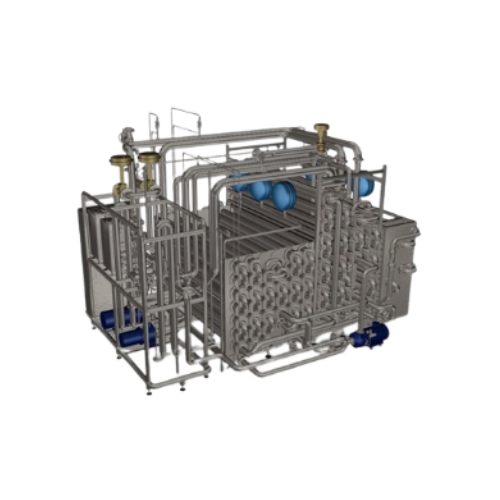

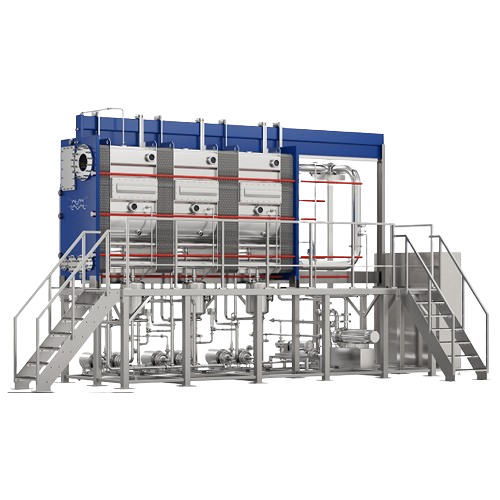

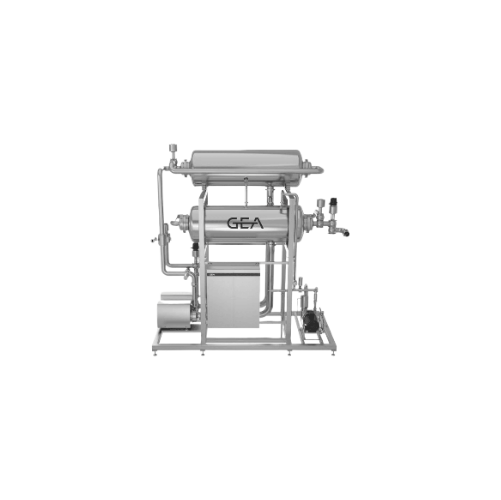

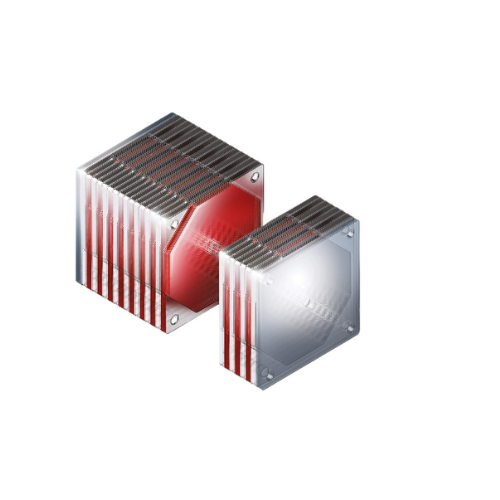

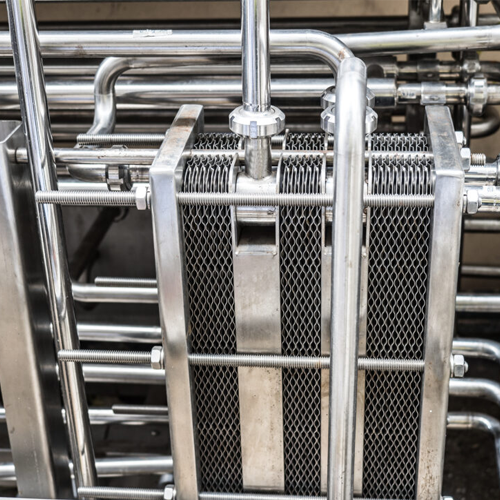

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

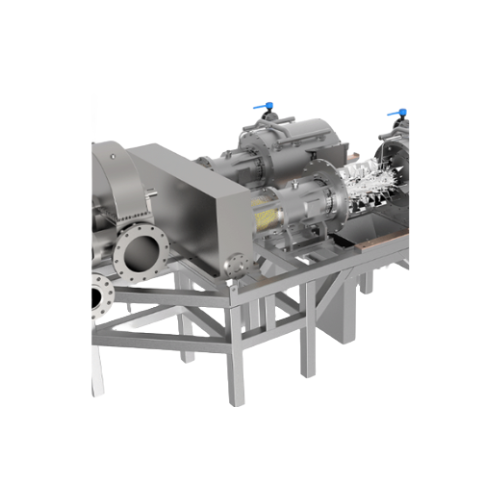

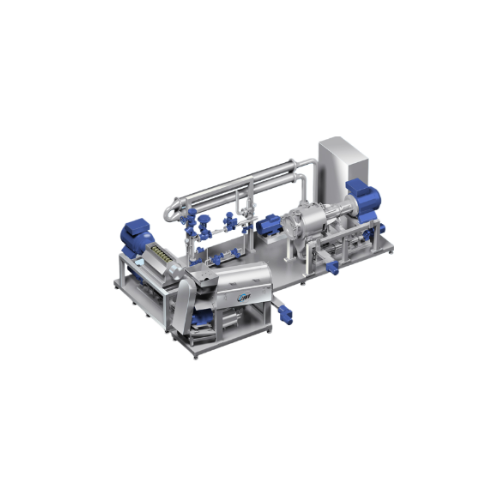

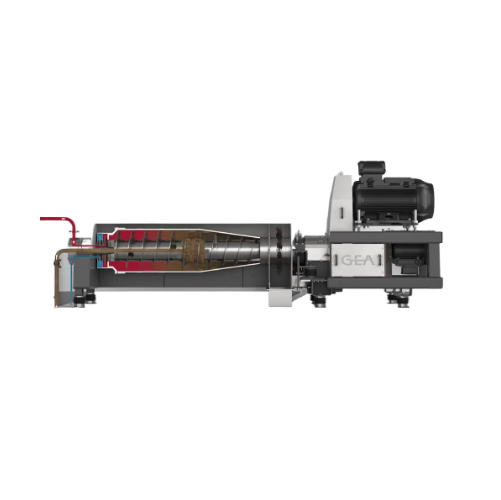

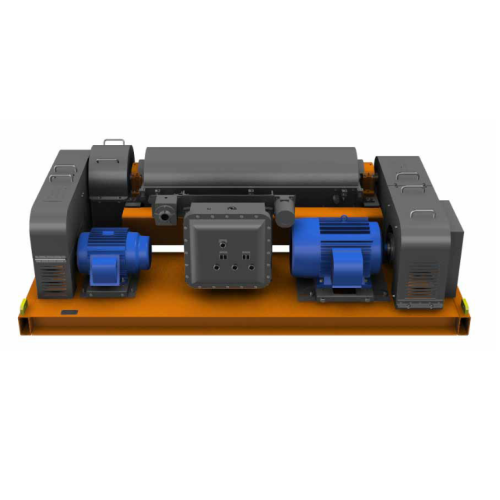

High-performance decanter centrifuge for dewatering

Achieve efficient and reliable dewatering by integrating a decanter c...

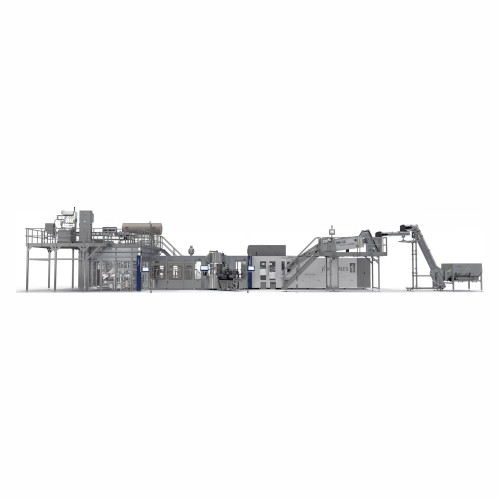

Milk powder processing plant

Achieve precise powder formulations with our state-of-the-art milk powder processing plant, ide...

Multistage mixer for emulsions and dispersions

Enhance your production with a versatile multistage mixer that ensures opti...

Multistage mixers for emulsions and dispersions

Experience efficient emulsification and dispersion processes with this ver...

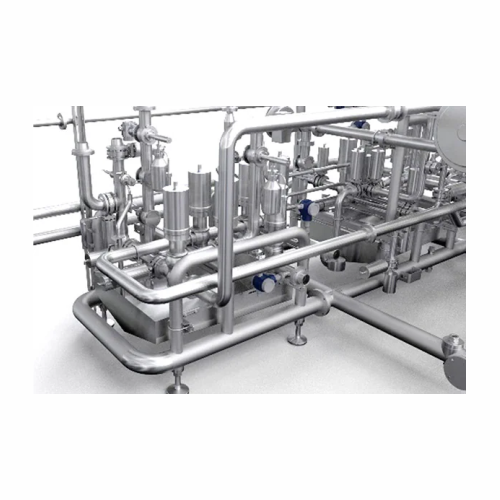

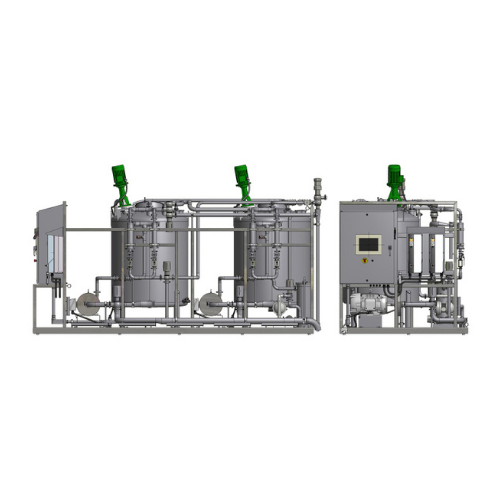

Cip systems for dairy production

Ensure consistent hygiene and sanitation levels in your production line with efficient, aut...

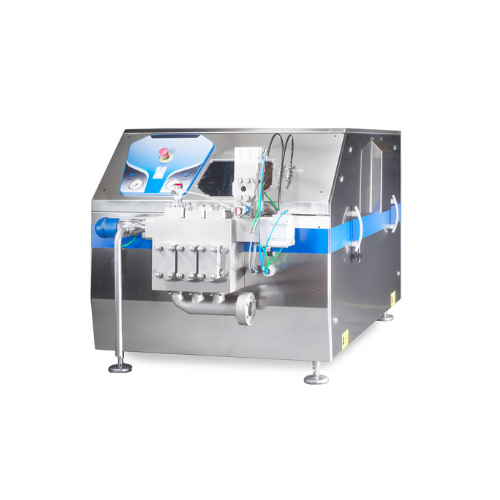

Industrial homogenizers for dairy products

Maximize consistency and quality in your production of milk products and bevera...

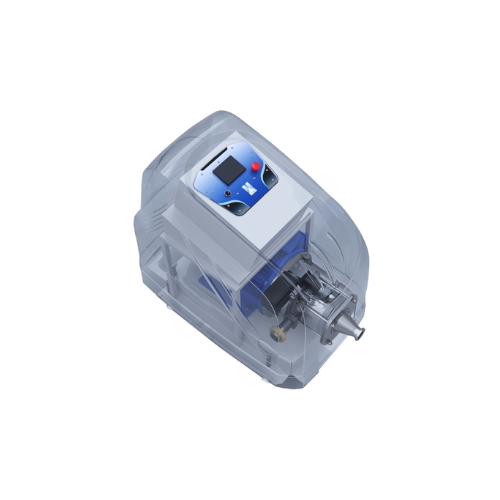

Centrifugal pumps for food & beverage and biopharmaceutical applications

Optimize your liquid transfer processes with p...

Aseptic sampling devices for biopharmaceutical applications

Secure aseptic sampling ensures your high-value biopharmaceu...

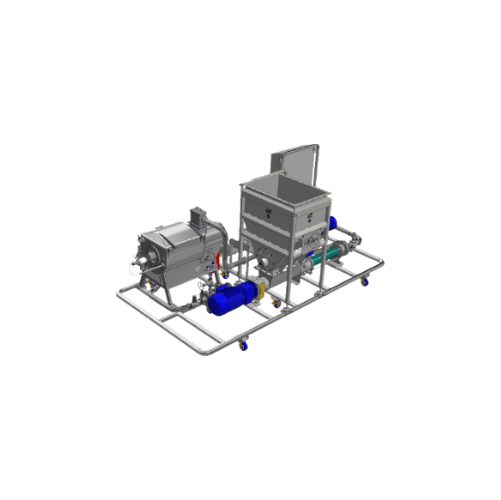

Compact cleaning in place units for food industry

Optimize your production line with a compact system designed for effici...

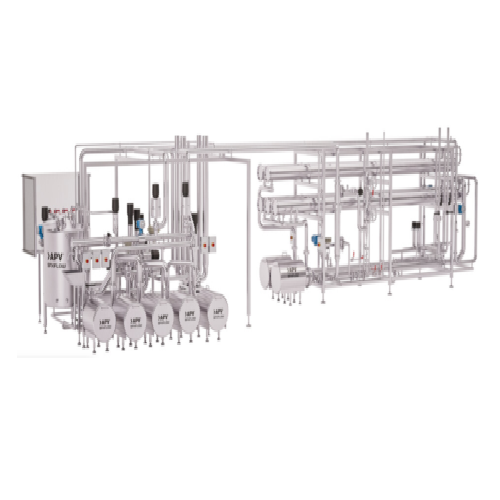

Cleaning-in-place for multiple equipment in food industry

Ensure precise hygiene and traceability with a system designed...

Stainless steel process vessels for biopharmaceutical applications

Ensure seamless mixing and sterilization with engine...

Automation for food processing

Optimize your food production with cutting-edge automation, enhancing efficiency and precisio...

Batch processing systems for industrial applications

Optimize batch production with versatile systems that enhance energy...

Cip cleaning systems for food and beverage industry

Optimize your cleaning operations with seamless Clean-in-Place and St...

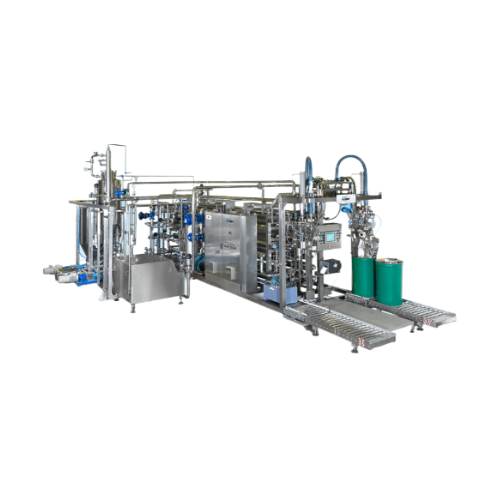

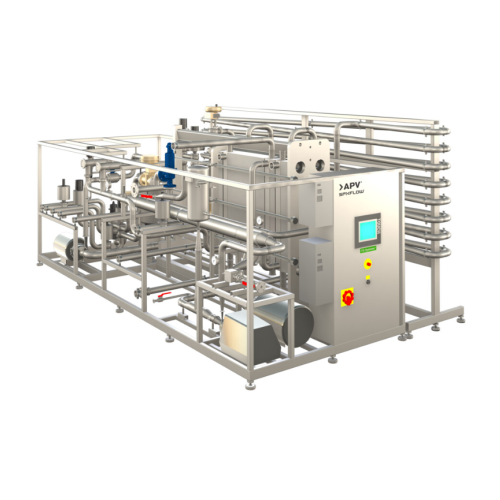

Inline processing system for food and beverage production

Optimize your production line with a versatile inline processi...

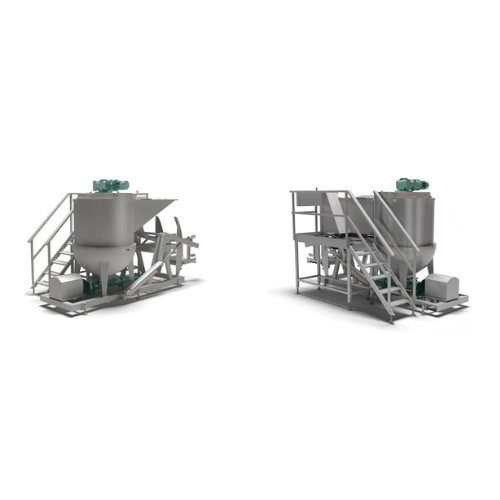

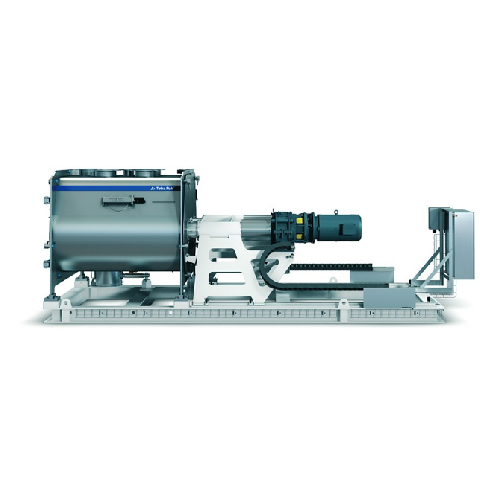

Industrial premixing system for batch and inline processing

Streamline your production with advanced premixing systems d...

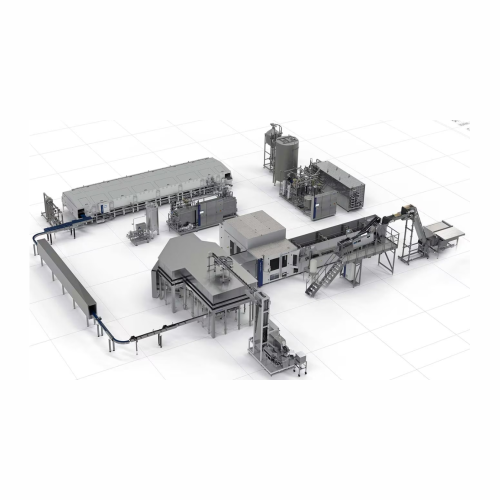

Turnkey food and beverage processing solutions

Optimize your production line with integrated processing systems designed t...

Tangential filtration system for wine production

Achieve precise filtration, purification, and concentration of compounds ...

Automatic filtration system for beverage industry

Enhance your beverage production with a multi-stage filtration system t...

Clean-in-place system for industrial cleaning needs

Optimize your production efficiency with a system that seamlessly int...

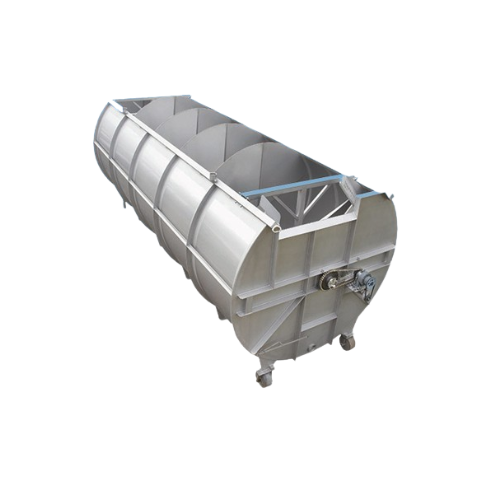

Industrial cooling vessel for ready meal components

Enhance your production with precise cooling and gentle handling of t...

Mayonnaise production system

Ensure precise emulsification for low to full-fat mayonnaise and similar cold emulsions with a ...

Aseptic storage tanks for high efficiency applications

Ensure consistent aseptic storage and efficient handling of variou...

Compact production unit for liquid food products with varied viscosities

Streamline your batch production with this ver...

Scraped surface heat exchanger for food processing

Efficiently handle temperature-sensitive food products with a compact ...

Pig systems for product recovery in food and beverage industry

Maximize yield and minimize waste with advanced PIG syste...

Hygienic fluid storage tanks for food industry

Ensure impeccable hygiene in fluid storage with our customizable tanks, des...

Aseptic thermal processor for high viscosity products

Optimize your processing of high viscosity products with precise te...

Nanofiltration and reverse osmosis for wine processing

Streamline your beverage production by effectively concentrating l...

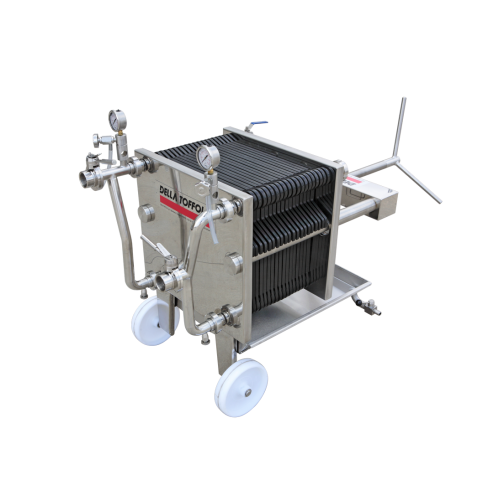

Plate and sheet filter for wine and vinegar

Optimize the filtration of liquids like wine and vinegar with this versatile s...

Plate flash pasteurizer for wine

Ensure optimal microbial inactivation while maintaining product quality with high-efficienc...

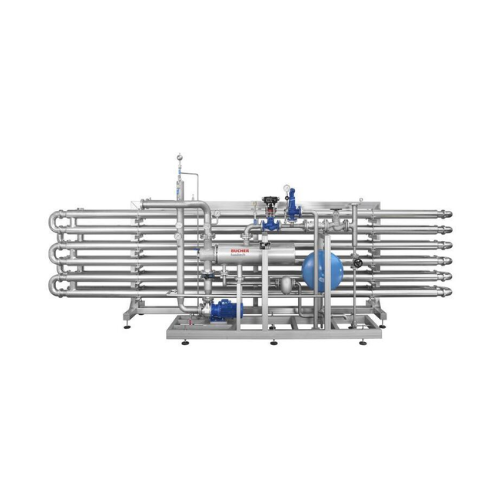

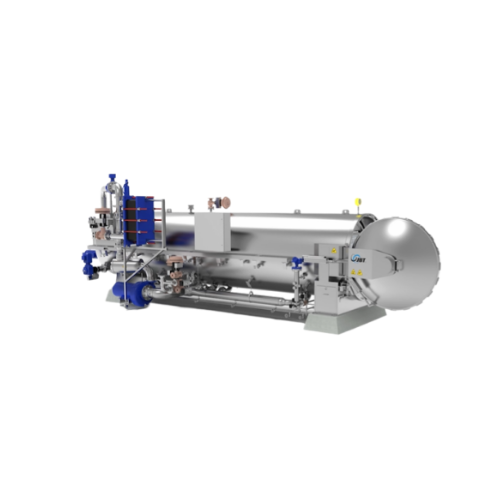

Tubular pasteurizer for wine, grape juice, and dairy

Ensure product integrity by efficiently inactivating microorganisms ...

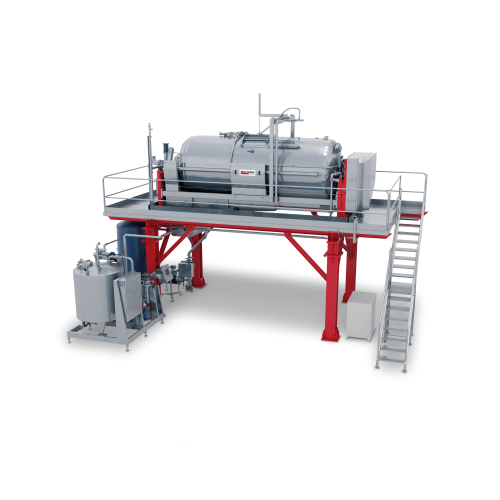

Continuous flotation unit for grape juice

Efficiently separate solids from liquids in grape and fruit juice production, ac...

Cip system for wine, grape juice, oil, and dairy

Ensure optimal hygiene and operational efficiency in processing lines wit...

Crossflow filter for wine and grape juice

Efficiently streamline your beverage filtration process with a versatile crossfl...

Desulphurizer for grape juice

Eliminate sulfur dioxide vapor release while preserving juice concentration, achieving purity ...

High solids crossflow filter for wine filtration

Optimize filtration efficiency while minimizing operational costs with th...

Evaporators for grape juice and dairy products

Optimize the concentration of grape juice and dairy products with precision...

Horizontal plates d.e. filter for wine and vinegar

Optimize filtration and purification across liquids with precision, en...

Vertical leaves pressure filter for wine and viscous liquids

Ensure optimal clarity and consistency in your liquid produ...

Ion exchange system for wine and grape juice stabilization

Enhance wine and grape juice quality by achieving consistent ...

Aseptic buffer tanks for pilot scale process lines

Ensure seamless production flow and quality control in sterile environ...

Advanced closed blending vessels for liquid food products

Enhance your production line with advanced closed blending ves...

Hygienic buffer tanks for process optimization

Enhance your production flow with hygienic buffer tanks that ensure consist...

Laboratory in-line sterilization system

Ensure precise temperature control and rapid cooling for diverse liquid application...

Small-scale scraped surface heat exchanger for high-viscosity products

For R&D teams tackling complex formulations...

Direct steam injection Uht pilot system

Elevate your production capabilities with a sanitary UHT pilot system designed for ...

Pilot system for high-viscosity product processing

Efficiently handle high-viscosity or large particle products with this...

Aseptic filler for nutraceuticals

Ensure the sterility of your liquid nutraceuticals and beverages with a versatile solutio...

Aseptic bag-in-box filler for laboratory use

Achieve aseptic filling precision on a lab-scale with a compact solution that...

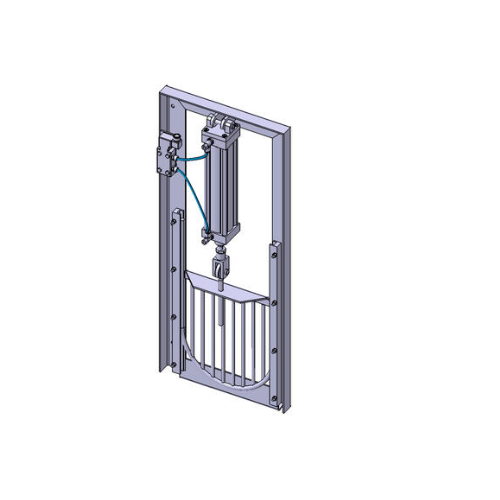

Fs closing devices for industrial packaging solutions

Streamline your packaging process with versatile closing devices, d...

Lab-scale high-pressure homogenization solution

Optimize your lab-scale production with precision homogenization, ensuring...

Pilot homogenizer for high-pressure inline homogenization

Achieve precise homogenization and emulsification across vario...

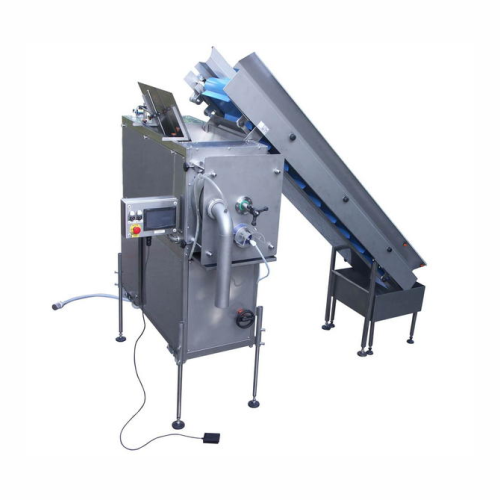

Small-scale in-container spray pasteurizer for laboratory use

Optimize your R&D processes with precise control over...

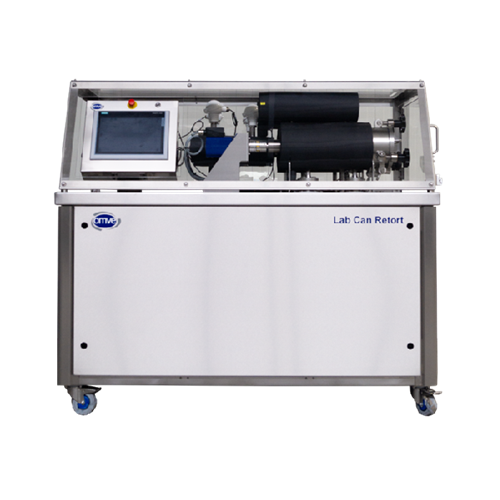

Lab can retort for precise temperature and pressure control

Achieve precision in recipe validation and packaging testing...

Batch deaerator for reduced oxidation in liquid processing

Optimize product shelf life and quality by efficiently removi...

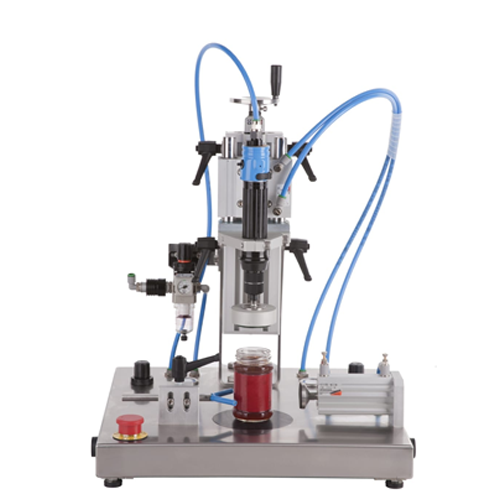

Crown cork sealer for liquid food packaging

Ensure reliable sealing for bottled beverages and dairy with a compact, table-...

Counter-pressure filler for carbonated drinks

Enhance your carbonated beverage production with advanced counter-pressure f...

Customized process plants for plant-based beverages

Efficiently scale your production of plant-based beverages with modul...

Lab-scale carbonation system for beverage filling

Streamline your beverage development with precision carbonation and ver...

Unpacker for return bottles

Effortlessly manage return bottle operations with high-speed unpacking solutions that ensure pre...

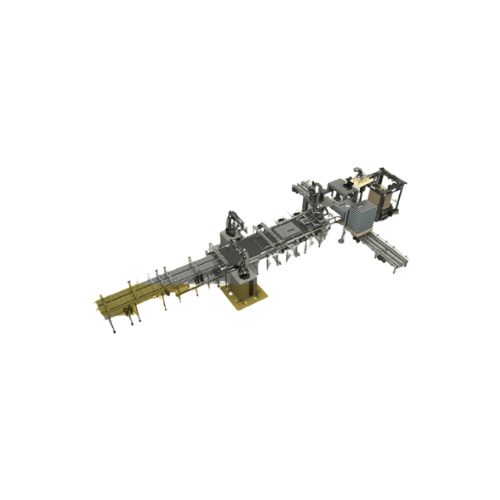

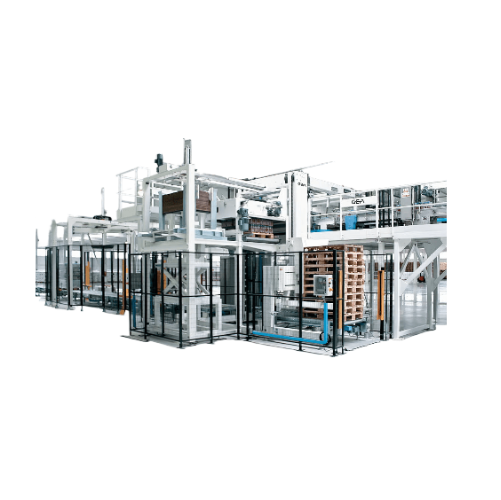

Automatic palletizer for bottle packaging lines

Streamline your bottling line with advanced palletizing solutions engineer...

Automated case erector for american cases

Streamline your packaging line by efficiently erecting American-style cases with...

Rotary weight filler for edible oil

Optimize your liquid product filling with precise weight control, ensuring high accurac...

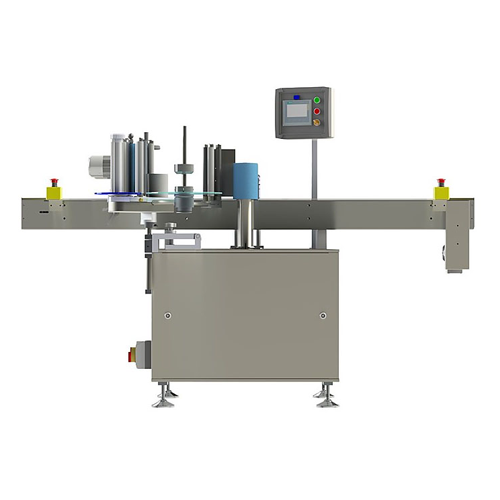

Rotary labeling solution for bottles and containers

Optimize your labeling process with high-speed precision, handling va...

Semiautomatic labelling solution for cylindrical bottles

Effortlessly apply precise labels to various cylindrical and squ...

Interlayer sheet dispenser for palletizing

Enhance your palletizing efficiency by integrating a compact interlayer sheet d...

Automatic stretch wrapper for food and beverage industry

Optimize your packaging line with a high-speed stretch wrapper t...

Medium-speed shrink-wrapping solution for various packaging types

Streamline your end-line packaging with a modular shr...

Combined packaging solution for shrink wrapping and wrap-around cartons

Elevate your packaging line with an integrated ...

Rotary weight filler for Pet and Hdpe bottles

Enhance your production line with precise weight-based filling, ensuring rap...

Depalletizer for cases and crates

Efficiently streamline your high-speed production line by seamlessly transferring cases a...

Shrink wrapping solution for low-speed packaging

Achieve seamless low-speed packaging with a shrink wrapping solution desi...

Laser diffraction particle size analyzer

Achieve precise particle size analysis with laser diffraction technology, ensuring...

Cleaning-in-place (cip) systems for hygienic processing

Elevate hygiene standards in your liquid processing line with an ...

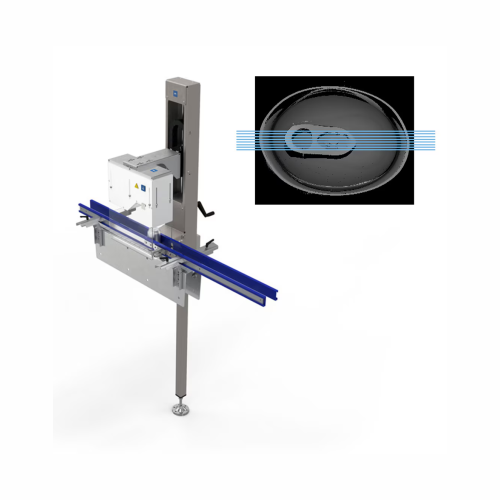

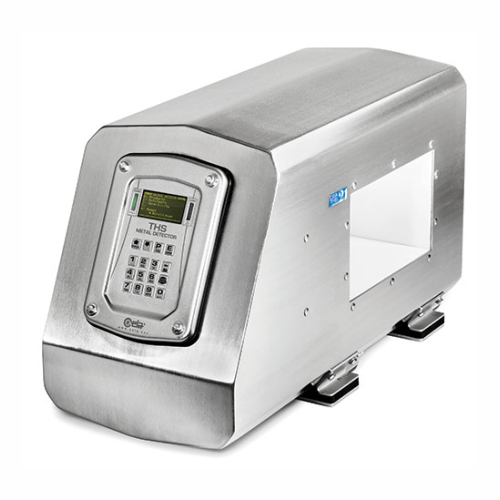

Industrial metal detector for food production lines

Ensure product safety and compliance by seamlessly detecting metal co...

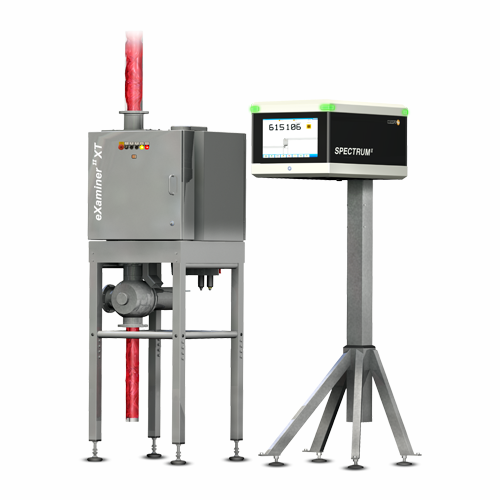

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

Cryogenic chilling systems for food processing

Efficiently maintain precise temperatures to enhance product quality and sa...

Cryogenic freezer for food industry applications

Efficiently tackle high-speed freezing and chilling challenges with a ver...

Volumetric filler for liquid and viscous products

Achieve precise and adaptable filling for a wide variety of liquid and ...

Jar sealing system for plastic and glass containers

Achieve precise and efficient sealing of plastic and glass jars with ...

4 head sealing system for plastic and glass jars

Achieve precision sealing for jars of various materials with this high-sp...

Jars and bottles rinsing solution

Ensure impeccable hygiene and particle-free cleanliness for your jars and bottles by inte...

Semi-automatic packaging system for sauerkraut and vegetables

Efficiently tackle the challenge of packing sticky product...

Automatic dosing and packing system for cabbage and sauerkraut

Streamline your vegetable processing line with a robust, ...

Inspection table for vegetables and fruits

Streamline your quality control with an efficient inspection table designed for...

Hydraulic juice press for fruit and vegetables

Streamline your juicing operations with this hydraulic solution, expertly d...

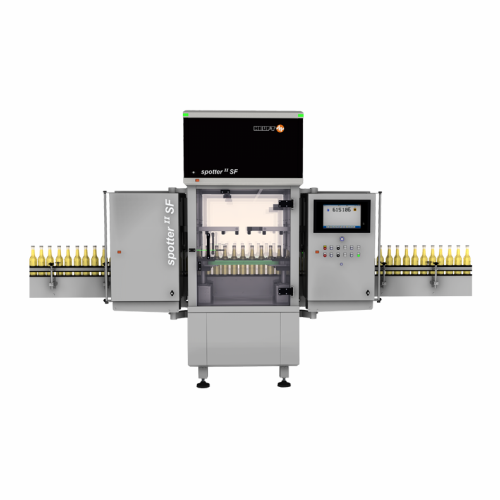

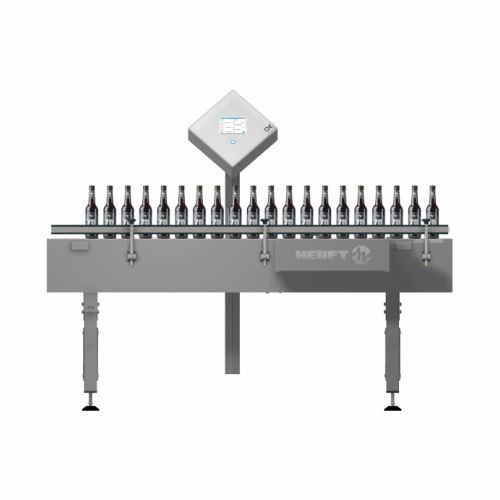

Inspection system for returnable glass containers

Ensure the safety and quality of your beverage containers with a precis...

Compact tunnel pasteuriser for beverages

Ensure beverage safety with precise pasteurisation in a compact design that integr...

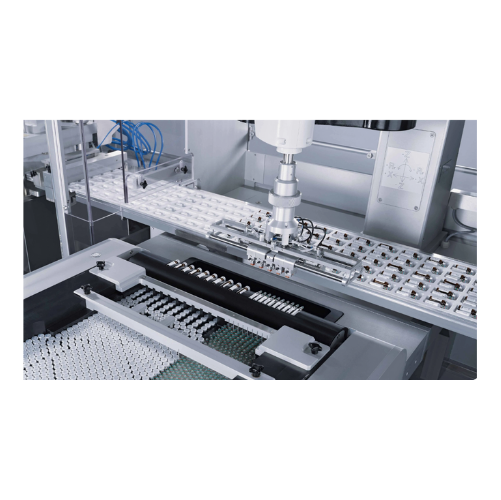

Intelligent pre-dosing system for fruit juices

Optimize your beverage production by minimizing fruit piece damage and ensu...

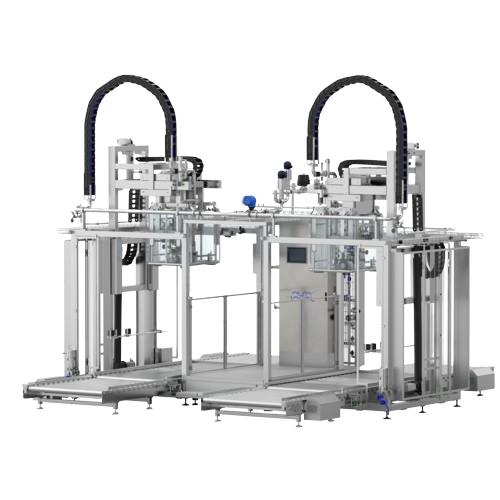

Ultrahygienic block for aseptic filling

When handling sensitive beverages, ensuring microbiological safety and quick produc...

Flash pasteuriser for juices

Ensure the highest quality of juices and beverages with a versatile system that offers precise ...

High-performance stretch blow moulding and labelling system

Maximize space and efficiency with this compact system that ...

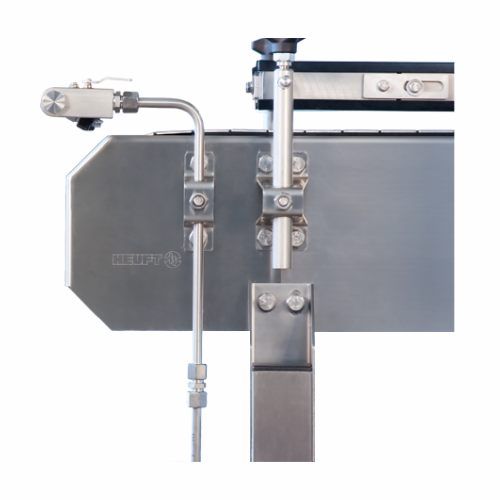

Crate washer with adaptive jetting units

Ensure consistent cleanliness of beverage crates with a washer that adapts to vary...

Container sweep-off depalletiser

Enhance your beverage production line efficiency with a high-performance depalletising solu...

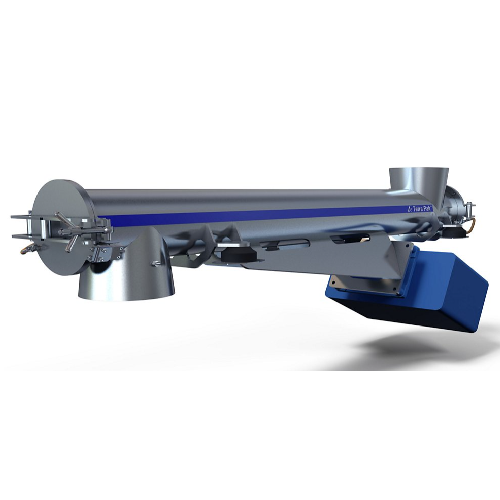

Juice product deaerator

Ensure high-quality filling without foam formation through efficient deaeration, perfect for manufact...

Palletizing grouping system for non-returnable packs

For beverage and packaging lines, precise and rapid palletizing of n...

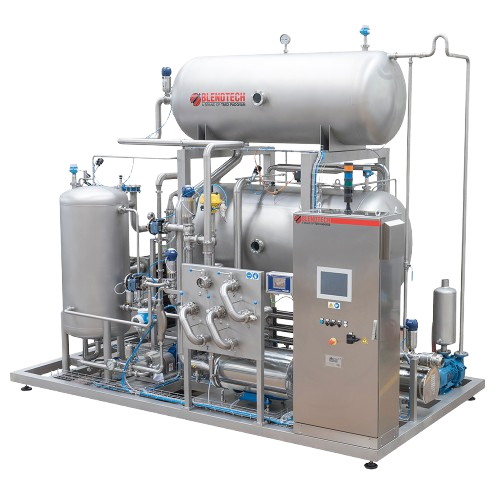

Syrup room for customized beverage ingredient preparation

Achieve unparalleled flexibility in beverage production with a...

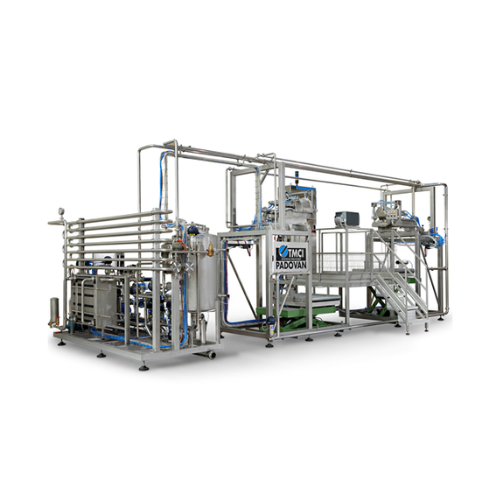

Uht system for milk products

Achieve optimal product safety and quality for dairy and plant-based beverages with precise UHT...

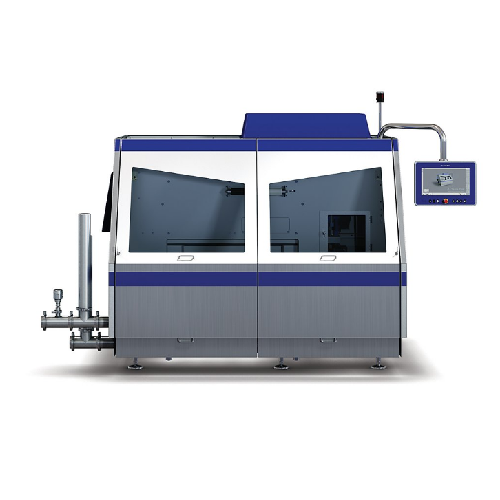

Flash pasteuriser for juice production

Ensure the microbiological safety and quality of your juice products with precise th...

Heat exchanger for beverage production

Ensure your beverages maintain their quality and safety with a versatile heat exchan...

Stretch blow moulder for Pet containers

Optimize energy efficiency and production versatility with this stretch blow moulde...

Compact fill level and cap inspection system

Ensure flawless beverage quality by integrating a compact system for precise ...

Crate washer for beverage manufacturers

Ensure thorough cleaning of beverage crates with an advanced washing system featuri...

Empty bottle inspector with deep learning

Ensure that every beverage container in your production line is pristine with cu...

Flexible packaging line for beverage production

Streamline your beverage production with a flexible system capable of hand...

Can inspection unit for quality control

Ensure the integrity of your beverage cans with precise defect detection and qualit...

Caustic residue detection for bottle washing

Ensure product purity by detecting and eliminating residual caustic in return...

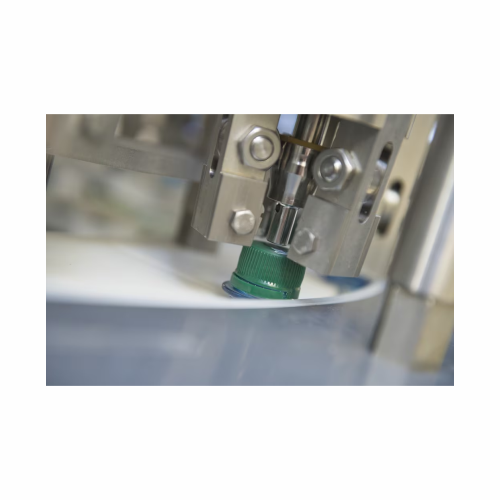

Inspection systems for fillers and cappers

Ensure precise fill levels and secure cap placements with advanced inspection s...

Leakage detection for beverage cans

Ensure each canned beverage leaves your facility ready to impress, with precise leak de...

Cip system for cleaning bottling lines and processing sections

Ensure a sterile production environment by integrating a ...

Preform and container inspection system

Ensure only flawless preforms and bottles continue in your production line with an ...

Decapper for removing screw caps

Efficiently unscrew caps from various bottle types without damaging the threads, even under...

Bottle inspection system for foreign particles detection

Ensure your beverage products remain uncontaminated with high-pr...

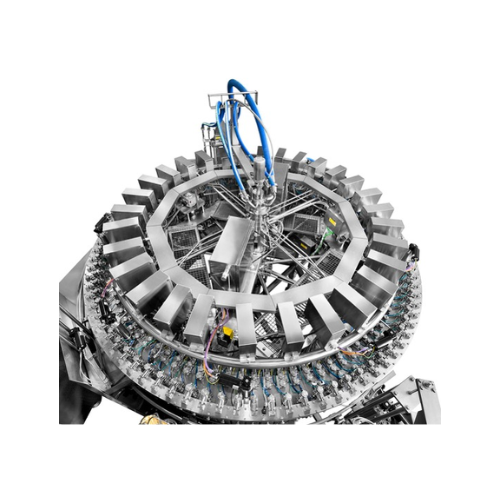

Innovative beer filling and capping technology

Revolutionize your filling process with an integrated system that combines ...

Sterile tank system for aseptic processing

Optimize your production with aseptic tank systems that ensure sterile storage ...

Aseptic bottle sterilisation system for Pet containers

Ensure aseptic integrity and high-speed efficiency in beverage pro...

Automated product change-over system

Maximize your production line efficiency by reducing downtime during product changeove...

Mixer for carbonated and non-alcoholic drink production

Efficiently mix and carbonate a variety of beverages while optimi...

Aseptic filling system for Pet containers

Ensure your beverage products maintain sterility and longevity with a high-speed...

Blow-moulder and labeller integration for Pet bottles

Streamline and enhance your PET bottle production with seamless blo...

Filler-seamer block for cans

For high-speed beverage production, this solution integrates filling, seaming, and cleaning in ...

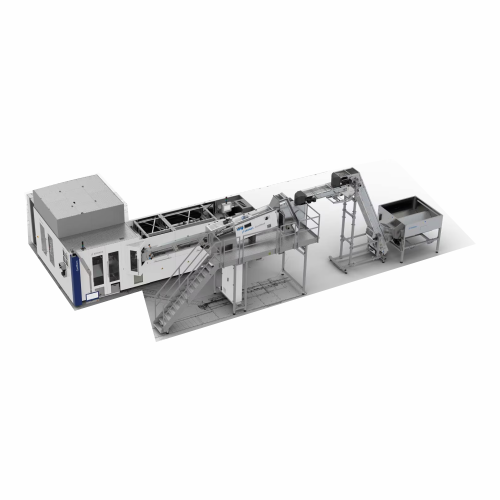

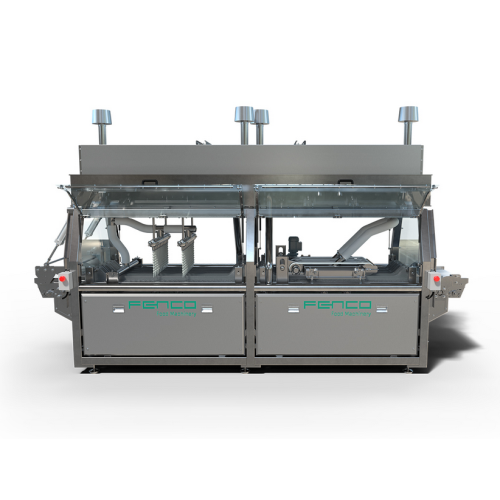

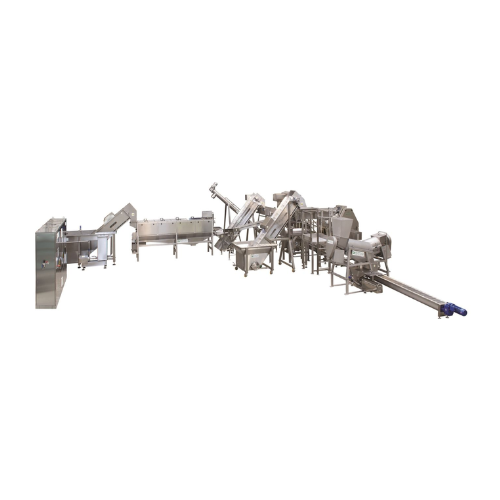

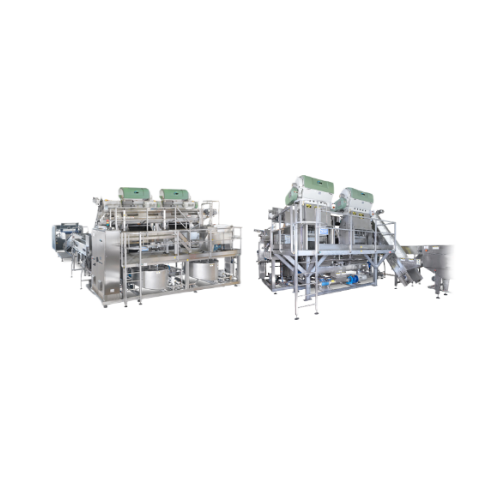

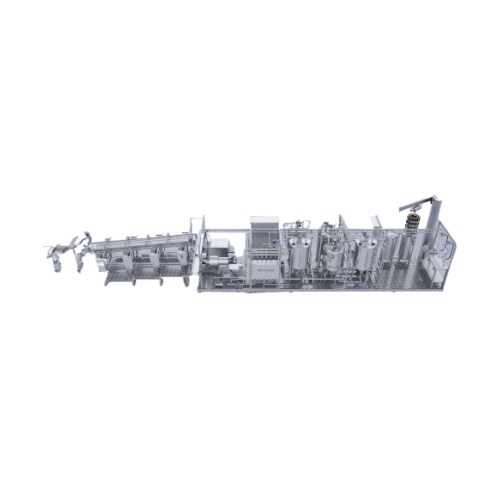

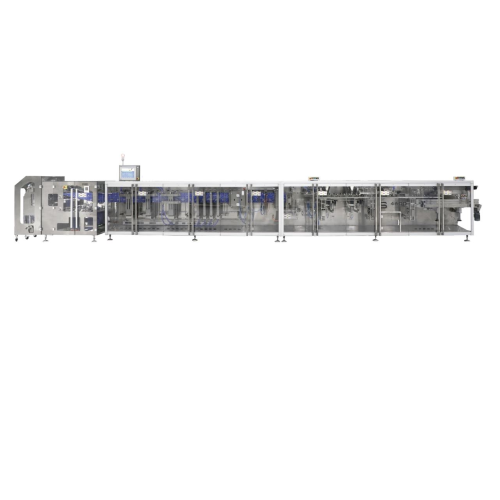

Fruit processing and packaging line

Streamline your fruit and vegetable processing with this semi-automatic system designed...

Grape destemming solution for efficient fruit processing

Streamline your fruit preparation process with a versatile machi...

Pasteurizing units for fruit and vegetable juices

Ensure your juices and purees remain fresh and safe by effectively past...

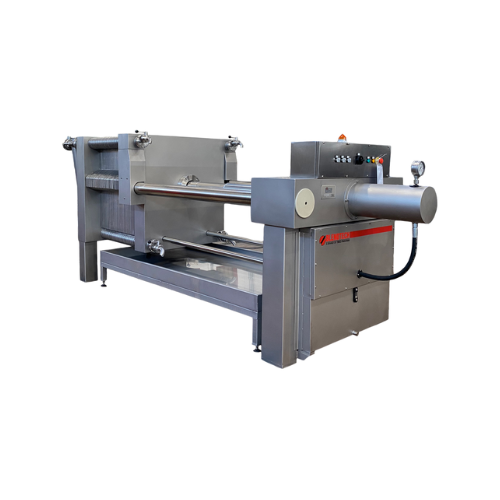

Stationary belt press for fruit juice extraction

Achieve optimal juice yield from fruits and vegetables through precise co...

Washing and grinding system for fruit and vegetables

Efficiently wash and grind fruits and vegetables to streamline your ...

Citrus fruit juicing system

Efficiently extract and refine citrus juices and oils with a streamlined system designed to hand...

Juice bottle and bag-in-box filling systems

Streamline your juice production with versatile filling solutions that accommo...

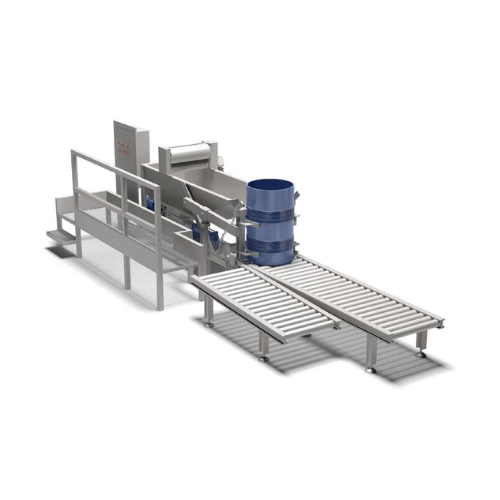

Fruit bin tipper for processing intake

Efficiently transfer fruits and vegetables from standard bins into your processing l...

Mobile juice processing units

Transform your fruit harvest into fresh, pasteurized juices directly on-site, ensuring optimal...

Ultrapure water demineralizer for critical boilers

Achieve high-purity water production with minimal chemical usage and a...

Mbr module for wastewater treatment

Optimize your wastewater management with efficient membrane bioreactors, designed to en...

Versatile syrup room systems

Streamline beverage production with a system that expertly handles dissolving, mixing, and past...

Flexible labeling system for returnable and non-returnable containers

Achieve precise labeling and enhanced alignment w...

Self-adhesive labeling for glass and Pet bottles and beverage cans

Maximize your production efficiency with a labeling ...

Flexible packaging system for beverage containers

Streamline your packaging process with a modular system that adapts sea...

Enclosed film packaging solution

Eliminate the need for corrugated trays and minimize packaging waste with a robust solution...

Demineralization and carbonation for bottled table water

Ensure consistent carbonation and precise blending for beverage ...

Batch sugar dissolver for syrup production

Streamline your syrup production with precise control over sugar dissolution, w...

Continuous sugar dissolver for syrup production

Effortlessly convert crystal sugar into high-quality syrup with a system d...

Bright beer tank cellar for beer storage

Enhance your beverage production efficiency with a fully automated solution that m...

Water deaerator for beverage production

Enhance the quality and extend the shelf life of your beverages with our cutting-ed...

Filter system for beverage stabilization and clarification

Ensure your beverages are crystal clear and stable with a ver...

Energy-efficient hot filling system for beverages

Optimize your beverage filling processes with a system that ensures pre...

Blending system for fine adjustment of original gravity in beer

Ensure precise control over your beer’s original gravity...

Continuous flash pasteurizer for beverage shelf life extension

Maximize beverage shelf life with precise microbial and e...

Blending system for deaeration and carbonation of beverages

Achieve precise blending, efficient deaeration, and accurate...

Aseptic linear filler for sensitive beverages

Experience unparalleled versatility and efficient aseptic filling with advan...

Stretch blow molding with integrated coating for Pet bottles

Enhance product longevity and quality by integrating stretc...

Pet bottle stretch blow molding with coating and filling

Extend the shelf life of your beverages and liquid products with...

Transparent glass barrier coating for Pet bottles

Ensure the longevity of sensitive beverages and liquid foods with glass...

Cold aseptic filling system for beverages

Ensure microbiological safety and high product quality with a versatile cold ase...

Carbonating solution for precise Co2 content in beverages

Enhance your beverage production with seamless CO2 integration...

Compact cleaning system in container format

Optimize your production lines with a space-saving cleaning system capable of ...

Cip cleaning system for food and beverage production lines

Ensure microbiological safety and maintain quality standards ...

Dosing and blending system for beverage production

Enhance your beverage production with a flexible system capable of pre...

Multifunctional filter system for beverages and gases

Achieve precise filtration across multiple beverage and gas mediums...

Twin-column palletizer for flexible packaging feed

Optimize your production line with flexible and high-speed palletizing...

High-performance palletizer for cans, Pet, and glass containers

Elevate your palletizing efficiency with cutting-edge ro...

Pallet stacker/destacker for separator pallets

Optimize your pallet flow with an advanced stacking and destacking system d...

High-performance distribution and combining system

Streamline your packaging operations with a versatile system designed ...

Robotic layer grouping system for container distribution

Streamline your packaging line with precise, high-speed containe...

360° palletizing and depalletizing robot

Optimize your packaging flow with a robot offering seamless 360° operation for pre...

180° palletizing robot for automated palletizing and depalletizing

Optimize your production line with a versatile solut...

Flexible tunnel pasteurizer for beverage sterilization

Maximize product safety and flexibility in your production line wi...

Pet bottle filler for hot and cold still beverages

Achieve high-speed precision in filling and capping for various bevera...

Modular labeling system for beverage containers

Easily adapt to evolving labeling needs with this flexible system, designe...

Gentle container conveyor for bottles and cans

Achieve seamless container flow with minimal noise and enhanced precision, ...

Wrap-around packer for cartons and trays

Effortlessly streamline your packaging process with a high-speed solution designed...

Multifunctional packing system for beverage containers

Maximize your facility’s packing efficiency with a versatile...

Packer and unpacker for returnable and non-returnable containers

Streamline your packaging line with a versatile machine...

Depalletizer with accurate level compensation

Optimize your high-speed assembly line with a depalletizer designed for prec...

High-speed beverage industry palletizer

Optimize your palletizing process with a flexible, high-speed solution that adapts ...

Closure inspection system for crown corks and metal caps

Ensure product integrity with high-speed 360° closure inspection...

Industrial code verification system for product packaging

Ensure flawless packaging integrity with high-speed code verif...

Closure inspection system for beverage caps

Ensure complete closure integrity in high-speed beverage production lines with...

High-precision fill level checker for beverages and containers

Ensure precise fill levels and prevent product wastage by...

Rejection system for standing bottles and cans

Ensure seamless quality control by precisely rejecting defective bottles an...

Label inspector for beverage and food containers

Ensure precise label application with high-speed inspection, crucial for ...

Pallet inspection system

Ensure the stability and integrity of diverse pallets with a high-speed inspection system that minim...

Container rejection system for high-speed operations

Ensure product safety by swiftly removing defective containers at hi...

Bottle filler for beer and soft drinks in glass bottles

Achieve precision in bottling with reduced CO2 emissions and low ...

Pvpp beer stabilization system for breweries

Reduce beer hazing and extend shelf life with this advanced stabilization sys...

Crossflow filter for liquid filtration in food industry

Enhance your liquid filtration process with a versatile crossflow...

Horizontal element kieselgur filters

Enhance your production with a filtration system that ensures effective separation of ...

Industrial sheet filter for liquid filtration

Optimize your liquid product purity with precise filtration, maintaining int...

Vacuum rotary filter for liquid filtration

Enhance your production line’s efficiency with precise filtration, ensuri...

Htst pasteurization system for liquid foods

Ensure your liquid products are safe and long-lasting with high-temperature-sh...

Industrial skids for liquid processing

Efficiently manage large-scale liquid and solid processing in your production line w...

Industrial magnetic agitator for homogenizing pharmaceutical products

Achieve precise dispersion and homogenization in ...

Portable agitator for high-speed mixing

Enhance your liquid formulation processes with an efficient solution for rapid mixi...

Powder blender for liquid mixing applications

Optimize your process with a compact blender designed to efficiently dissolv...

Centrifugal separators for dairy products

Enhance your liquid food product quality with centrifugal separators designed fo...

Automated Cip system for small facilities

Ensure impeccable hygiene with a mobile cleaning system designed to efficiently ...

Cip cleaning system for dairy industries

Ensure hygienic operation with this system, designed to maintain optimal cleanline...

Sugar dissolving system for industrial applications

Efficiently dissolve sugar and low-viscosity blends to achieve perfec...

Agitators for mixing tanks

Optimize mixing operations with versatile agitators designed for various viscosities and fluid ty...

Oxygen and carbon dioxide monitoring and elimination system

Achieve precise control over dissolved gases with a system t...

In-line additive dosing systems for beverages

Ensure precision and safety in beverage production by integrating in-line do...

Piping discharge system for product separation in transfer lines

Optimize your beverage production by preventing product...

Micro-filtration system for beverage industry

Achieve microbiological stability at cold temperatures with our micro-filtra...

Powder mixing system for beverage industry

Enhance your beverage production with an advanced powder mixing system that ens...

Wine recovery system for bottling processes

Streamline bottling operations by recovering and re-dosing valuable wine, redu...

Co2 dosing system for effervescent beverage bottling

For beverage manufacturers requiring precise carbonation, this solut...

Automated system for cleaning in place (cip)

Ensure thorough, efficient cleaning of your production equipment with a syste...

Intermittent motion cartoner for pharma packaging

Streamline your packaging line with versatile cartoning solutions that ...

Linear labelling system for vials and bottles

Streamline your labelling process with a compact solution designed for preci...

Rotary capper for round and irregular shaped containers

Efficiently cap round and irregular containers with precision and...

Rotary unscrambler for plastic bottles

Streamline your bottling process with a solution that efficiently sorts, orients, an...

High-speed drift-dwell motion doypack forming system

Optimize your liquid packaging efficiency with a dual-motion system ...

Form fill and seal solution for liquid and pasty products

Enhance your production efficiency with high-speed forming, fi...

Top loading case packer for loose or bundled bottles

Effortlessly handle and pack both standard and uniquely shaped bottl...

Over wrapping solution for foodstuffs and beverages

Optimizing film over wrapping for challenging thin materials, this co...

Cup forming, filling, and sealing solution

Optimize your cup production with a compact solution designed for precise formi...

Bottle bundling and shrink wrapping system

For high-speed beverage packaging, streamline your process with advanced bundli...

Rotary doypack packaging system for various materials

Enhance your packaging line with versatile doypack machines designe...

High-pressure homogenizers for liquid products

Achieve consistent emulsions and stable dispersions with high-pressure homo...

Homogenizer for high-pressure homogenization

Optimize your production with high-pressure homogenization, essential for ach...

High-pressure homogenizer for food and pharmaceuticals

Achieve unparalleled consistency and stability in emulsions and di...

Homogenizers for high-pressure applications

Achieve unparalleled product consistency and stability with precision-engineer...

High-pressure homogenizers for dairy and food products

Achieve consistent texture and stability in your liquid products w...

High-pressure homogenizers for dairy and beverage industries

Achieve precise emulsion stability and consistent particle ...

Hydrogen compression solution for refueling stations

For operations demanding efficient hydrogen compression, this modula...

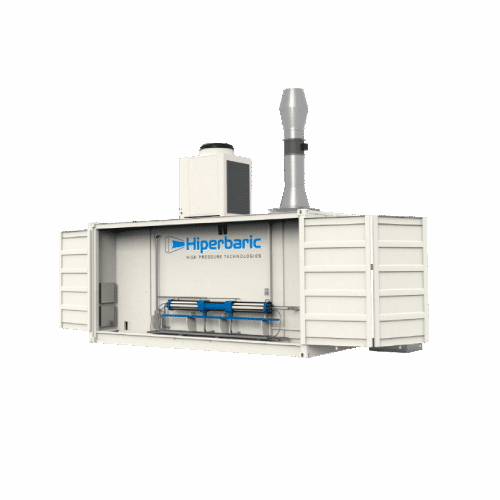

High pressure processing for bulk liquid beverages

Streamline your liquid processing with high-pressure in-bulk technolog...

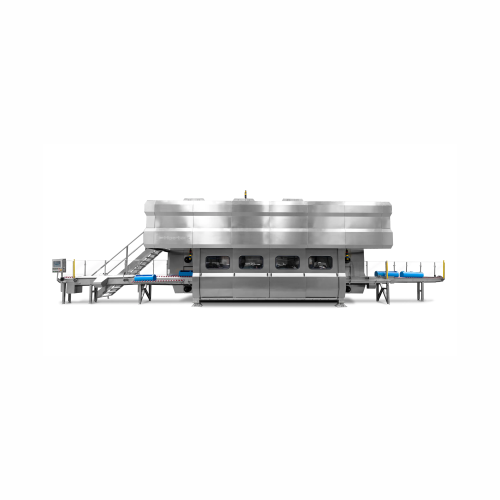

High pressure food processing system

Achieve extended shelf life and enhanced food safety with a cutting-edge high-pressure...

Hpp system for small-scale food production

Enhance food safety and prolong shelf life with this compact high pressure proc...

Compact full product inspection system for pharmaceuticals

Easily detect fill level inaccuracies, closure misalignments,...

Leak detection for pharmaceutical containers

Ensure the integrity of your liquid products in high-speed production by dete...

Full container check for fill level and closure inspection

Ensure the integrity of your liquid products with this advanc...

Leak detection system for plastic containers

Ensure product integrity and prevent costly recalls with this advanced system...

Pulsed x-ray foreign object inspection for food packaging

Ensure your packaged goods are free from dangerous contaminant...

Foreign object detection for packaged and unpackaged food

Ensure the integrity of packaged and unpackaged foods by detec...

Pipeline inspection for liquid and paste-like products

Ensure your liquid and paste-like products are free from foreign o...

Final product inspection system for pharmaceutical containers

Ensure the integrity and precision of packaged pharmaceuti...

Full container inspection for glass and Pet bottles

Ensure the highest product quality by detecting foreign objects and m...

Closure inspection for beverage containers

Ensure the integrity of your bottled products with precision closure inspection...

Automatic leakage detection for Pet bottles

Ensure the integrity of bottled beverages by detecting even the smallest leaks...

Semi-modular labeller for precise beverage bottle labelling

Achieve millimeter-precision bottle labelling with seamless ...

Versatile labeller for food industry

Enhance your packaging line with a versatile labelling machine capable of applying wra...

Labelling solution for food and beverage containers

Optimize your packaging line with precision labelling technology that...

Foreign object inspection for full containers

Detect and remove minute foreign objects from liquid and paste-like products...

X-ray assisted empty bottle inspection

Enhance your production line with advanced X-ray and optical technology to ensure pr...

Fill level and closure inspection system

Ensure precise fill levels and secure closures in high-speed liquid packaging envi...

Final container inspection for beverages

Ensure flawless product presentation and secure branding by detecting misaligned l...

Full container inspection system

Ensure the quality and safety of your products with a compact solution that performs precis...

Conveyor system for efficient container transport

Optimize your filling line with a versatile container transport system ...

Empty bottle inspection for beverages

Ensure high quality control and prevent contamination in beverage production lines wi...

Empty bottle inspector for beverage industry

Ensure flawless quality control by thoroughly inspecting empty bottles for de...

Ferrous-in-foil metal detection system

Enhance quality control for foil-packaged goods with precise ferrous metal detection...

X-ray inspection system for contaminant detection

Detect and eliminate foreign contaminants in a wide range of food produ...

X-ray inspection system for low-density foreign objects

Enhance your inspection capabilities with advanced X-ray technolo...

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

Multi-spectrum metal detector for food industry

Achieve unmatched detection accuracy in your food processing line with thi...

Bucket conveyor for wet and dry free-flowing products

Seamlessly elevate, lower, or convey free-flowing products without ...

X-ray inspection system for identifying foreign bodies in food products

Ensure precise detection of foreign materials i...

X-ray inspection system for detecting foreign objects in food products

Ensure product safety and quality by detecting e...

Industrial heat recovery system

Transform exhaust heat from fryers into usable energy, reducing operational costs and boosti...

Incline transfer conveyors for dry, fresh, and frozen food products

Efficiently transfer a variety of solid and granule...

Thermal treatment units for wine processing

Optimize your wine and spirits production with precise temperature control, en...

Juice storage tank with hygienic and cooling options

Ensure optimal freshness and stability of juices and beverages with ...

Stainless steel buffer tanks for food, pharma, and cosmetics

Ideal for maintaining process fluidity, these stainless ste...

Industrial continuous distillation system

Enhance product purity and efficiency with a robust continuous distillation syst...

Stainless steel chocolate tank for storage and processing

Efficiently control temperature and consistency for chocolate ...

Centrifugal disc filter for solid-liquid separation

Optimize solid-liquid separation in your processing line with an adva...

2-phase separator for clarifying liquids

Efficiently refine and clarify liquids while minimizing waste. This 2-phase separa...

Industrial belt press for fruit and vegetable processing

Optimize your juice yield and reduce drying costs in starch and ...

Efficient drying solution for food packaging pouches

Optimize your packaging line with precise moisture control, ensuring...

System for receiving, sorting, and destoning fruit

Enhance your fruit and tomato processing efficiency with an integrated...

Aseptic sterilizer for fruit-based products

Ensure product safety and extend shelf life with advanced sterilization techno...

Industrial dicer and peeler for fruit processing

Achieve seamless integration in your processing line with a dicing and pe...

Enzyme inactivators for tomato processing

Efficiently inactivate enzymes to preserve nutritional value and organoleptic qu...

Forced circulation evaporators for tomato concentration

Achieve significant energy savings and enhance production efficie...

Tomato juice extractor

Achieve optimal juice extraction with efficient separation and minimal waste—ideal for producers aimin...

Tomato receiving and sorting system

Ensure top-quality tomato products by efficiently handling unloading, washing, and sort...

Aseptic sterilizers for tomato products

Ensure your tomato-based and fruit products remain safe and shelf-stable with advan...

Aseptic filler for bag-in-box packaging

Achieve unparalleled product safety and quality in liquid packaging with our advanc...

Fruit juice pre-concentrator

Enhance your juice concentration process with a system that increases brix levels efficiently, ...

Enzymatic inactivators for fruit juice extraction

Optimize your fruit juice extraction process by ensuring precise contro...

Evaporator for pulpy juice concentration

Achieve efficient concentration with reduced energy consumption, thanks to innovat...

Juice extractor for fruit and vegetable processing

Maximize juice yield and enhance pulp quality with high-performance ex...

Aseptic filler for large bags

Ensure safe and sterile packaging of liquid and slurry products in large formats with this ase...

Sterilizer for liquid and viscous products

Effortlessly process and sterilize diverse liquid products, from concentrated j...

Aseptic filling system for bag-in-box packaging

Efficiently fill a range of liquid products into pre-sterilized bags while...

Aseptic filler for bag in box packaging

Optimize your bag-in-box packaging process with high-speed aseptic filling, ensurin...

Aseptic bag-in-box filler for juices and purees

Enhance your filling operations with a high-speed aseptic solution designe...

Aseptic filler for liquids and semi-concentrates

Ensure maximum sterility and precision when filling liquids, concentrates...

Self-adhesive labeling system for unstable cylindrical containers

Ensure precise labeling of unstable cylindrical conta...

Self-adhesive labeling for multi-format containers

Ensure precision on diverse container shapes with a high-speed, self-a...

Linear self-adhesive labeller for cylindrical and flat containers

Optimize your labelling process with precision applic...

Cold glue label applicator for pre-cut labels

Optimize your packaging line with high-speed labeling for a variety of conta...

Rotary hot melt labeller for pre-cut labels

Achieve precise high-speed labelling of diverse containers with enhanced adhes...

High-speed labeling heads for industrial applications

Enhance your production line efficiency with high-speed labeling he...

Fermenter for microbial fermentation processes

Optimize your fermentation and biopharmaceutical production with stainless ...

Liquid food filling solutions

Maximize efficiency in your packaging line with versatile filling machines designed for precis...

Conical powder mixer for uniform powder blending

Achieve consistent powder blending while preserving the integrity of deli...

Stainless steel fermentation tanks

Optimize your fermentation efficiency with stainless steel tanks that provide precise te...

Ultraclean aseptic storage tanks for hygienic liquid food

Ensure your liquid products remain uncontaminated and maintain...

Automated cleaning in place (cip) systems for beverage processing

Optimize your production with automated CIP systems t...

Pulsed electric field system for olive oil processing

Enhance extraction efficiency and product quality with this advance...

Compact pulsed electric field treatment for french fries

Reduce oil absorption and enhance product texture with this inno...

Pulsed electric field treatment for roots, tubers, and fruits

Enhance your production line with advanced pulsed electric...

Cell disintegration measurement tool for food products

Ensure precise measurement of cell disintegration across food prod...

Modular pulsed electric field system for food processing

Enhance your food processing efficiency with a modular system th...

Precision quality control for potato and vegetable cutting

Optimize cutting precision and improve product quality by ins...

Evaporation plant for liquid mixtures

Achieve precise thermal separation of multi-component liquid mixtures, optimizing con...

Reverse osmosis with remineralization for drinking water production

Enhance your beverage production with precise water...

Crossflow filtration with ceramic membranes for wines

Enhance filtration efficiency and durability with ceramic membranes...

Rotary vacuum filters for wine and lees filtration

Achieve high-precision liquid filtration and separation with continuou...

Rotary vacuum filters for wine and beverage filtration

Efficiently filter and clarify wines, juices, and industrial fluid...

Industrial sheet filters for diverse liquid filtration applications

Achieve precise liquid filtration with adaptable sh...

Nanofiltration systems for water pretreatment

Achieve precise water quality with advanced nanofiltration systems designed ...

Reverse osmosis systems for industrial water treatment

Achieve optimal water purification in beverage production lines wi...

Fully automatic continuous flow wine press

For winemakers seeking to optimize operations, this advanced pneumatic pressing...

Industrial crossflow filters with ceramic membranes

Achieve precise filtration with robust ceramic membranes, ideal for h...

Electronic filling system for non-carbonated beverages

Optimize your bottling process with precision filling technology t...

Gravity filling systems for still beverages

Ensure precise and clean filling for still beverages with gravity systems that...

Hot beverage gravity filling system

Ensure precise hot filling of beverages with gravity-fed accuracy, handling liquid temp...

Wine clarification flotator

Achieve superior wine clarity efficiently by integrating a single-tank flotation solution that s...

Continuous wine flotation unit for must clarification

Enhance your must clarification process with a continuous flotation...

Continuous flotation units for wine clarification

Optimize your wine and juice production with our advanced flotation uni...

Continuous sugar dissolving system for beverage production

Effortlessly transform granulated sugar into a consistent, hi...

Concentrate drum emptying system

Efficiently extract every drop of fruit concentrate from your drums with precision and ease...

Kieselgur filter for beer filtration

Achieve crystal-clear beer without compromising flavor through efficient kieselgur fil...

Sheet filters for wine and beer filtration

Enhance your filtration process with reliable sheet filters designed for high-q...

Automated Cip systems for beverage and food industry

Ensure high hygiene standards in your production line with advanced ...

Dilute-phase conveying solution for powder handling

Efficiently transfer powders and granules with robust leak containmen...

Inline high-shear mixer for powders and liquids

Achieve efficient mixing and homogenization in your production line with a...

Mixer for low to medium viscosity products

Optimize your mixing, dosing, and homogenization processes with a versatile mix...

Inline high shear mixing unit for low to medium viscosity products

Achieve precise emulsification and size-reduction wi...

Vacuum high shear mixer for medium to high viscosity products

Achieve flawless blending and air-free consistency in visc...

Bigbag discharge system for food, chemical, and pharmaceutical industries

Ensure precise and dust-free handling of bul...

Bigbag filling system for powder and bulk materials

Ensure precise and dust-free bigbag filling with this versatile syste...

Freeze dryer for high sugar or acid content products

Achieve precise moisture control for challenging high sugar or acid ...

Industrial low temperature freeze dryer for high sugar or acid content products

For processing challenging high sugar ...

Low temperature freeze dryer for high sugar or acid content products

Perfect for producing freeze-dried goods from food...

Tunnel pasteurizer for beverages

Optimize your beverage production with precise pasteurization control, ensuring product qua...

Premix system for carbonated beverages

Ensure precise carbonation and blending for your beverage lineup with this advanced ...

Liquid confectionery metering system

Effortlessly integrate precision and flexibility in candy production by accurately met...

Robotic palletizer for material handling

Experience seamless and efficient palletizing with advanced robotic solutions desi...

Robotic handling systems for beverage containers and bins

Streamline your container handling with precision-engineered r...

Industrial can seamers for food and beverage packaging

Streamline your canning process with precision seaming solutions d...

Industrial spiral freezing system

Optimize your food processing line with a reliable spiral system, designed to efficiently...

Sterilizers and pasteurizers for industrial food processing

Optimize thermal processing for viscous foods and beverages ...

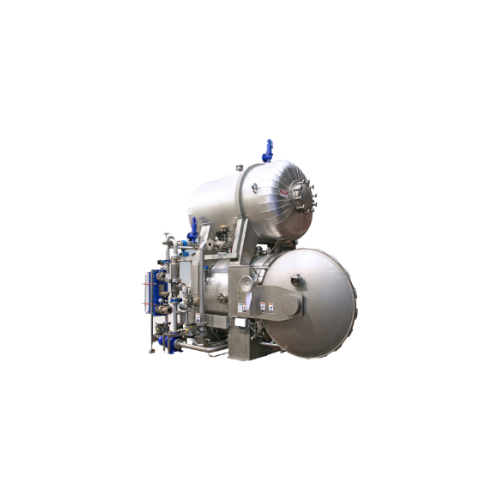

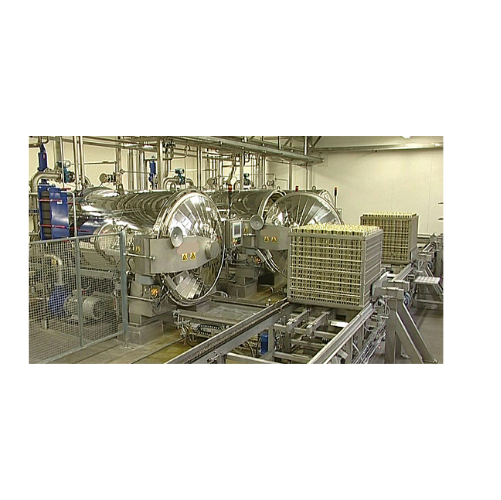

Batch retorts for food sterilization and pasteurization

Achieve optimal sterilization and pasteurization of packaged food...

Powder dissolution unit for beverage production

Achieve precise and rapid dissolution of powders like sugar and acids, opt...

Tomato processing crushing mill

Optimize your production line with efficient chopping and refining, ensuring uniformity and ...

Robotic depalletizers for bins

Efficiently optimize your warehouse space while ensuring precise and adaptable material handl...

Enzymatic inactivation system for fruits and vegetables

Achieve optimal product quality by maintaining vivid color, robus...

High-precision rotary weight filler for edible oils and sauces

Achieve exceptional filling precision with solutions desi...

Self-adhesive labelling system for bottles

Enhance your bottling line with a versatile labelling system that supports medi...

Compact wet glue labeling system for low volume production

Achieve precise, high-quality labeling with compact machinery...

High-speed wet glue labelling system

Ensure precise labelling on diverse bottle types with our versatile rotary labelling s...

Compact combined labelling solution for bottling lines

Optimize your bottling line with a versatile, compact labelling so...

Combined wet glue and self-adhesive labeling system

Achieve seamless labeling with combined wet glue and self-adhesive te...

Self-adhesive labeling system for bottles

Streamline your bottling operations with high-precision labeling that enhances p...

Semi-automatic filler for bag-in-box packaging

Streamline your liquid packaging process with a versatile filler that integ...

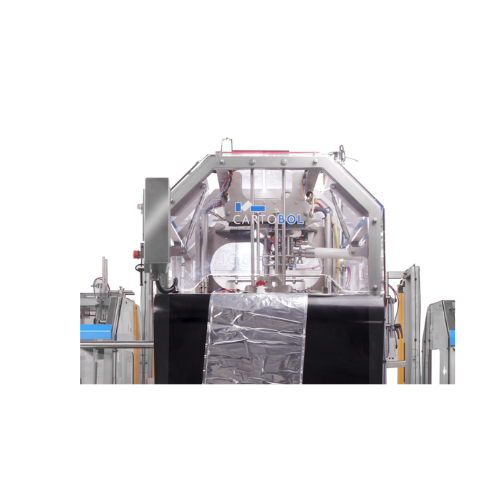

Bag-in-box carton erector

Experience seamless carton erection with advanced servomotor technology, enhancing both efficiency...

Automatic palletiser for bag-in-box packaging line

Streamline your packaging process with a cartesian palletiser designed...

200l buffer tank for bag-in-box fillers

Ensure precise filling and consistent flow control with this stainless steel buffer...

Bag-in-box fully automatic filling line

Streamline your liquid packaging operations with a modular system designed to enhan...

Buffer tank for bag-in-box filling

Optimize your liquid packaging with precise flow control and pressurization, ensuring st...

Manual bag-in-box filling solution

Streamline your liquid packaging with a compact, easy-to-operate filling system that sim...

Manual filling system for bag-in-box packaging

Streamline your liquid filling process with a manual system designed for pr...

Semi-automatic aseptic filler for single bags

Ensure aseptic integrity and flexibility for your liquid and semi-liquid pro...

Shrink-sleeve application system for packaging

Enhance your packaging line with efficient, precise shrink-sleeve applicati...

Rotary continuous motion bottle cleaning solution

Ensure pristine product integrity by effectively eliminating particles ...

Storage tanks for wine preservation

Ensure optimal preservation of beverages with robust storage solutions featuring precis...

Cross-flow lees filter for wine and juice lees

Optimize your beverage filtration process by ensuring high-quality output a...

Thermostabilizer for beer and wine sterilization

Ensure biological stability in beverages by efficiently inactivating yeas...

Vacuum concentrator for juice and chemical processing

Reduce energy and concentration costs significantly while enhancing...

Tray lid packer & case erector for packaging lines

Efficiently manage packaging lines by seamlessly integrating tray lid ...

Robot module for aligning sorting and loading products

Optimize your packaging line with a versatile robot module that al...

American case packer & case erector for Rsc cartons

Streamline your end-of-line packaging by efficiently erecting and pac...

Conveyor system for aligning, sorting, and transporting products

Streamline your packaging line by efficiently aligning,...

Parallel evaporation system for laboratory sample preparation

Achieve precise sample concentration and drying with autom...

Cross-flow filtration unit for clarifying juice and wine

Achieve optimal clarity and yield with this semicontinuous cross...

Ion exchange system for fruit juices and syrups

Enhance juice quality and optimize sugar processing with efficient ion exc...

Commercial juice mixing station

Streamline your beverage production with precise mixing and dosing, ensuring consistently hi...

Mash heater for core fruits and berries

Improve juice extraction and color yield in your fruit processing line with this in...

Aseptic filtration system for juice production

Ensure the microbiological quality and turbidity of juices and concentrates...

Industrial pasteurizer for juice, dairy, and vegetable purees

Ensure product safety and extend shelf life with this comp...

Crusher system for frozen juice processing

Effortlessly process frozen juices and concentrates by efficiently crushing, me...

Pneumatically controlled dosing slide for pome fruit silos

Ensure consistent and controlled fruit discharge in your proc...

Drum dumper for emptying liquid juice drums

Streamline liquid juice extraction by efficiently emptying and transferring dr...

Tubular falling film evaporator for fruit juice concentrates

Optimize your fruit juice concentration process with seamle...

Citrus juice extractor

Achieve unparalleled juice purity and essential oil separation with a system that elevates your fruit ...

Grinding mill for apple and pear mash

Optimize your fruit and vegetable processing with a high-speed, energy-efficient grin...

Hydraulic press for juice extraction from apples

Optimize juice yield and purity with a robust hydraulic pressing system, ...

Cross-flow filtration for wine and fruit juice

Achieve high-quality filtration and purification for liquid and slurry prod...

Industrial Cip system for fruit juice production lines

Ensure optimal hygiene and operational efficiency with advanced CI...

Grinding mill for apples and pears

Optimize juice yield with tailored grinding for a variety of fruits and vegetables, ensu...

Adsorber for haze stabilisation in clear fruit juices

Achieve precise haze stabilization and debittering in fruit juices ...

Measuring mixer for small grain samples

Optimize the precision of your formulation processes with a solution designed for p...

Evaporator for juices and purees

Efficiently concentrate liquid products like apple juice, tomato puree, and chocolate sauce...

Evaporators for fruit and vegetable juices and purees

Optimize your juice and puree production with advanced evaporators ...

Vacuum degasser for juices and purees

Enhance the quality of your liquid products with efficient degassing and flavor recov...

Storage tank for dairy products and juices

Designed for optimal preservation and hygiene, these storage tanks prevent sedi...

Pasteuriser and cooler for fruit and vegetable juices

Ensure optimal thermal treatment for your fruit and vegetable produ...

Pasteurizer and sterilizer for fruit and vegetable juices

Ensure the safety and quality of your fruit and vegetable juic...

Fruit and vegetable washing solution with agitating action

Experience efficient dirt removal and product agitation for f...

Aseptic filling system for fruit juices and nectars

Effortlessly integrate aseptic filling into your beverage production ...

Syrup room for beverage production

Optimize your beverage production with advanced syrup room solutions, offering precise c...

Industrial sugar dissolver for soft drink and juice production

Effortlessly produce high-quality sugar syrup essential f...

Tunnel pasteurizer, heater, recooler for fruit juices and soft drinks

Optimize your beverage production with a versatil...

Ultrafiltration for fruit juices and nectars

Optimize your juice and nectars production with precise ultrafiltration, ensu...

Horizontal plate filtration for fruit juices

Ensure optimal clarity in beverage production with a filtration unit that exp...

Diatomaceous earth pressure filter for fruit juices and soft drinks

Achieve exceptional clarity and taste in your bever...

Plate and sheet filter for fruit juices

Ensure precision and clarity in your beverage production by utilizing this advanced...

High solids crossflow filter for fruit juices and nectars

Eliminate the challenges of suspended solids in beverage produ...

Deaeration system for fruit juices and soft drinks

Enhance your beverage quality by efficiently deaerating and carbonatin...

Enzyme inactivation for fruit juices and nectars

For fruit juice and nectar production, ensuring product quality starts wi...

Microfiltration system for fruit juice and soft drinks

Ensure optimal purity and flavor retention in your beverages with ...

Mixer-pasteurizer-carbonator for soft drinks and juices

Optimize your beverage production with a versatile system that se...

Plate flash pasteurizer for fruit juices and soft drinks

Ensure the purity and safety of your beverages with precision th...

Tubular pasteurizer for fruit juices and nectars

Preserve flavor and ensure safety in your beverage production with high-e...

Blending system for fruit juices and soft drinks

Optimize your beverage production with precise blending and carbonation, ...

Aroma-batch blender for beverage production

Optimize your beverage formulation process with precise aroma dosing and effic...

Batch blenders for fruit juices and nectars

Achieve precise ingredient ratios and uniform mixing in beverage production wi...

Carbonators for fruit juice and soft drinks

Achieve optimal carbonation in your beverages with precise CO2 dosing equipmen...

Syrup clarification for fruit juices and soft drinks

Enhance the clarity and quality of your beverages by efficiently rem...

Cleaning in place for fruit juices and soft drinks

Ensure maximum hygiene and reduce downtime in your beverage production...

Desulphurizer for fruit juices and nectars

Enhance beverage quality by efficiently removing sulphur dioxide from fruit jui...

Evaporators for fruit juices and syrups

Optimize your beverage production line with advanced evaporators designed to effici...

Apple processing equipment for juice and puree production

Efficiently process apples and pears into high-quality juice a...

Fruit juice extraction technology for Nfc and freshly squeezed juices

Optimize your juice production with advanced extr...

Juice reconstitution equipment for concentrated juice

Revolutionize your beverage production with advanced equipment desi...

Laboratory homogenizer for pharmaceutical and biotech applications

Achieve precise homogenization for your laboratory n...

High-pressure homogenizer for dairy and food production

Optimize your product consistency and stability with a high-press...

Industrial homogenizer for high pressure applications

Achieve consistent product texture and stability for your emulsions...

Industrial homogenizers for high-pressure applications

Optimize homogenization with high-pressure solutions designed for ...

No-oxygen wine filler

Ensure product integrity with advanced no-oxygen filling systems, designed to preserve delicate flavors...

No-oxygen filler for wine bottling

Enhance liquid bottling with seamless integration that minimizes oxygen exposure, ensuri...

High-capacity no-oxygen wine filler

Ensure optimal flavor retention and prevent oxidation in your bottling process with adv...

Industrial solutions for cap closures on bottles and containers

Achieve precise sealing for diverse bottle types with ou...

Industrial capping systems for bottling lines

Optimize your bottling process with versatile capping solutions designed for...

Industrial bottle cap closer for various caps

Ensure seamless closures for liquid products with versatile equipment design...

Cork and cap closures for bottling industry

Enhance your bottling efficiency with versatile corking and capping solutions ...

Colloidal mill for industrial homogenization

Achieve consistent emulsification, size reduction, and uniform particle distr...

Laboratory homogenizer for dairy and biotech applications

Ensure precise particle size reduction and consistent texture ...

Smoothies production line for fruits and vegetables

Optimize your smoothie production with a line designed for efficient ...

Industrial liquefying and crunching solution for frozen fruits and vegetables

Efficiently transform frozen produce int...

Industrial bottle rinsing systems

Ensure pristine bottle hygiene and maintain high production standards with advanced rinsi...

Crunching and dosing solution for frozen fruits and vegetables

Streamline your processing line with a versatile system d...

Colloidal mill for fine grinding and homogenisation

Optimize your liquid and semi-solid processing by achieving precise p...

Alternate movement bottle filling and capping system

Enhance your production line with a versatile filling and capping so...

Cip cleaning system for industrial processing lines

Ensure thorough removal of residue and contaminants from your product...

Co2/o2 beverage filling device

Ensure precise beverage analysis by maintaining carbonation integrity with a system that tran...

Packaged beverage analyzer for alcohol and Co2

Ensure precise beverage analysis with a streamlined solution that integrate...

Packaged beverage analyzer for beer, wine, and cider

Ensure precision in beverage quality control with rapid, direct samp...

Preform inspection system for blown containers

Ensure defect-free blown containers and minimize line jams with a robust pr...

Special checkweighers for industrial applications

Enhance your production line efficiency by precision weighing your prod...

Thread neck inspection for beverage bottles

Ensure bottle closure integrity by detecting subtle thread defects, such as cr...

Fill level inspection system for beverage bottling

Ensure compliance and optimize quality control with a system that accu...

Empty can inspection system for beverage industry

Quickly identify defects in empty cans to ensure quality and safety bef...

Co2 monitoring for dairy product contamination

Ensure product safety by rapidly detecting microbial contamination in dairy...

Full label inspection system for not-oriented containers

Ensure precise label application and integrity on any container ...

Oxygen concentration analyzer for beverage bottles

Accurately measure oxygen levels in your bottled beverages with non-de...

Gas analyzer for beverage bottle vacuum level

Ensure precise vacuum level measurement in bottle headspace with non-destruc...

Leak detection system for cans

Ensure the integrity and shelf-life of canned goods with precise leak detection, pressure mea...

Cap inspection and fill level inspection system for beverage containers

Ensure precise cap application and fill level m...

Cap quality inspection system for beverage industry

Ensure flawless cap performance and prevent production disruptions wi...

Combi x-ray and checkweigher for vertical products

Ensure accurate weight control and safety by detecting foreign bodies ...

Empty bottle inspection system for beverage industry

Enhance your production line’s efficiency by detecting defects...

Application angle inspection for Pet bottle caps

Ensure perfect cap alignment on PET bottles to prevent leaks and ensure e...

Blown bottle inspection system

Ensure the integrity and quality of your plastic containers with a high-speed inspection syst...

Decanter centrifuge for food industry separation

Achieve precise separation and ensure optimum product quality with our ad...

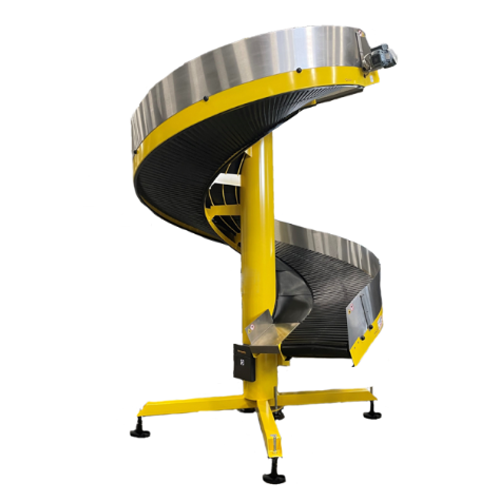

Spiral conveyor for logistics and packaging

Ensure seamless elevation and transportation of diverse products with this ver...

Narrow belt spiral conveyor for small packages

Optimize your production flow with this compact spiral conveyor system, des...

Modular conveyor system for internal unit load transport

Optimize your production line with a versatile conveyor system t...

Curved conveyor for logistics and packaging

Efficiently tackle space constraints in your production line with a flexible c...

Controlled spiral conveyor for logistic centers

Efficiently manage parcel flow and minimize product damage with this spira...

Spiral conveyor for repeating size cases

Optimize your line’s efficiency by elevating rigid items at higher inclines,...

Plate type pasteurizer for juice and tea drinks

Ensure optimal heating, sterilization, and cooling for juice and tea produ...

Semi-automatic Pet bottle blow molding solution

Optimize your production with precise and efficient blow molding for creat...

Semi automatic Pet bottle blow molding for 5l bottles

Maximize production efficiency by precisely forming PET containers ...

Semi automatic Pet bottle blow molding solution

Streamline your production with a semi-automatic solution designed for eff...

Semi automatic Pet bottle blow molding system

Enhance your production efficiency with a versatile blow molding system that...

Small bottle linear type beverage filling production line

Optimize your bottling efficiency with a high-speed solution d...

Automatic Pet bottle blowing solution

Achieve precise PET bottle molding with high-speed, automated operations that seamles...

Automatic wrap around hot melt glue labeling for Pet bottles

Enhance your production efficiency with a glue labeling sol...

Servo type Pet bottle blowing molding solution

Optimize your production with high-speed PET bottle molding, designed to st...

Industrial air cooled chiller for carbonated beverages

Optimize your beverage production with precise temperature control...

Automatic beverage bottle shrink packaging solution

Optimize your beverage packaging process with advanced shrink wrappin...

Automatic bottle cold glue labeling solution

Achieve precise labeling for diverse container types, enhancing your producti...

Automatic bottle self adhesive labeling solution

Enhance your production line with precision labeling for diverse containe...

Double sides adhesive sticker labeling solution

Achieve seamless and precise double-sided labeling on bottles and containe...

8000bph fruit juice filling system

Optimize your beverage production line with a high-speed fruit juice filling system, des...

Turnkey filling lines for packaging solutions

Optimize your production line with our turnkey filling solutions, designed t...

Centrifuge for citrus juice clarification

Optimize your juice production line with advanced centrifuge technology that ens...

Starch processing decanter centrifuge

Optimize starch and protein recovery with a versatile decanter centrifuge, ensuring h...

Centrifuge separator for food and beverage clarification

Ensure high efficiency and minimal product loss in your producti...

Bag-in-box filling solution for non-aseptic products

Maximize your production line’s efficiency with a high-speed f...

Plate heat exchanger sterilizer for food products

Ensure consistent product quality and microbiological stability in your...

Aseptic tank module for liquid food storage

Ensure safe storage of sterilized liquid foods with a customizable tank module...

Foodec decanter centrifuge for food processing

Achieve high yields and clear liquid separation in your food processing lin...

Climbing film plate evaporator for food industry

Efficiently concentrate heat-sensitive liquids while minimizing product e...

Forced circulation evaporator for high viscosity liquids

Optimize your production by efficiently concentrating viscous an...

Thousand-litre aseptic filler

Ensure the aseptic filling of bulk liquid and viscous food products, reducing contamination ri...

Aseptic processing equipment for food products

Optimize aseptic processing to ensure microbiological stability and product...

Automated Cip station for brewery cleaning

Ensure thorough hygiene and product integrity in your brewing process with a ve...

Gasketed plate heat exchangers for hygienic applications

Ensure optimal hygiene and thermal efficiency in your processing...

Gasketed plate heat exchanger for hygienic applications

Achieve precise temperature control for sensitive products with a...

High pressure gasketed plate heat exchangers for carbonated beverages

When ensuring high-pressure handling in your past...

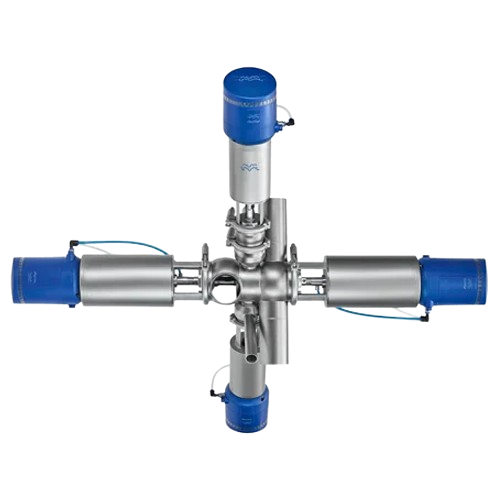

Aseptic mixproof valve for sterile processing

Ensure absolute product safety and optimize cleaning efficiency in sterile p...

Mixproof valve for cleaning-in-place control

Streamline your cleaning processes and ensure product safety with a versatile...

Double seat valve for hygienic processing

Eliminate cross-contamination risks and enhance efficiency with a modular valve ...

Air-operated single-seat valves for food and beverage industries

Achieve precise flow control and elimination of downtim...

Single seat valve for hygienic applications

Ensure optimal hygiene and safety with a versatile pneumatic valve designed to...

Aseptic magnetic mixer for hygienic production

Experience seamless mixing to the last drop with advanced levitating impell...

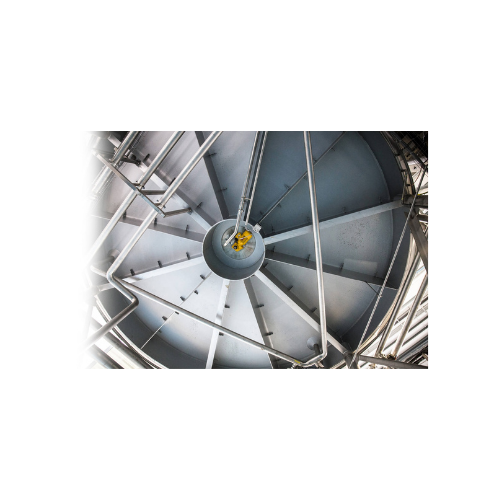

Rotary jet head tank cleaning system for food and beverage industry

Reduce your tank cleaning costs by up to 70% with a...

Automated butterfly valve actuator for hygienic processing

Streamline your flow control operations with a robust and mai...

Automated powder induction and dispersion system for industrial mixing

Achieve rapid and efficient incorporation of pow...

Atmospheric powder induction system

Enhance your mixing efficiency with a system designed for rapid powder induction and th...

Low-shear portable mixer

For processes demanding strict hygiene, this mixer eliminates rust and chipped coatings by offering ...

Bag and pouch filling solution for liquid products

Efficiently package diverse liquid products with precision and speed, ...

Filler and capper for bottles and jars

Optimize your production with a compact filling and capping solution that delivers f...

Automatic flowmeter filler for liquid packaging

Streamline your liquid production with precise filling capabilities, reduc...

Benchtop screw capper for diverse bottle sizes

Ensure precision and efficiency in your capping process with this adaptable...

Drum decanting unit for high viscosity liquids

Efficiently decant high viscosity liquids like solvent-based paints and ess...

Semi-automatic flowmeter boom filler for large volume containers