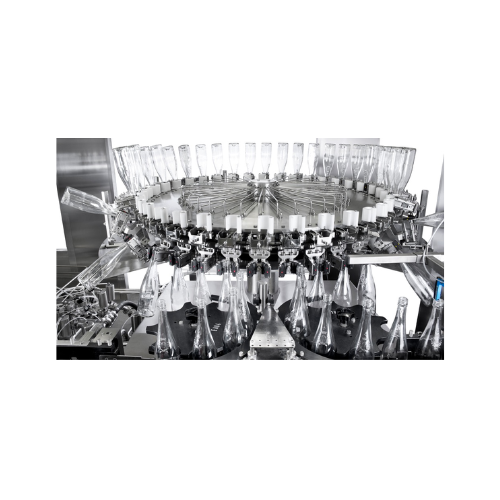

Industrial bottle rinsing systems

Ensure pristine bottle hygiene and maintain high production standards with advanced rinsing systems designed to optimize bottle preparation through versatile liquid and gas treatments.

Rinses and Sanitizes Bottles Efficiently

The rotary rinsers from Bertolaso offer an advanced solution for efficient bottle rinsing and sanitizing, crucial for beverage manufacturers and bottling companies. These systems utilize fixed or mobile nozzles for thorough cleaning—either with single or multi-stage treatments using liquid and gas. With production capacities ranging from 2,000 to 60,000 bottles per hour, they excel in high-speed, continuous operations. Ideal for a variety of applications, including wine, spirits, juices, and bottled water, the machines are designed for seamless integration into existing production lines. Built with energy-efficient rotary motion, they promote reduced energy consumption. Constructed from durable materials for optimal corrosion resistance, these rinsers support compliance with industry-specific cleaning standards. Moreover, their customizable features ensure versatility across different bottling requirements, while the robust design facilitates easy maintenance and long-term reliability.

Benefits

- Maximizes bottle throughput with capacities up to 60,000 bph for continuous high-speed operations.

- Reduces energy consumption with optimized rotary motion and multi-stage rinsing options.

- Enhances cleaning flexibility with customizable liquid and gas rinsing treatments.

- Ensures compliance with industry sanitation standards through effective bottle sanitizing.

- Lowers maintenance time and costs with robust, corrosion-resistant materials.

- Applications

- Beverages, Alcoholic drinks, Non-alcoholic drinks, Wine, Bottled water, Spirits, Juices

- End products

- Carbonated soft drink bottles, Cold-pressed juice bottles, Kombucha bottles, Wine bottles, Vodka bottles, Sparkling water bottles, Craft beer bottles, Whiskey bottles, Still water bottles, Herbal tea bottles

- Steps before

- Bottle production, Initial bottle cleaning

- Steps after

- Filling, Capping, Inspecting, Labeling, Packing

- Input ingredients

- bottles, sanitizing solution, filtered water, filtered air, inert gas

- Output ingredients

- rinsed bottles, sanitized bottles

- Market info

- Bertolaso (Omnia Technologies) is renowned for manufacturing high-quality, engineered-to-order bottling and packaging machinery, with extensive expertise in providing customized solutions for wineries and the beverage industry, ensuring efficiency, precision, and reliability in production processes.

- Production capacity

- 2, 000 to 60, 000 bottles per hour (bph)

- Rinsing type

- Fixed nozzle, Mobile nozzle

- Treatment type

- Liquid, Gas, Double treatment with liquid

- Triple treatment process

- Sanitizing solution, Filtered water, Filtered and oil-free air/inert gas

- Working mechanism

- Fixed nozzle / Mobile nozzle

- Production capacity

- 2, 000 to 60, 000 bottles per hour

- Rinsing treatments

- Single with liquid / gas, Double with liquid, Triple with liquid and gas

- Nozzle type

- Fixed / Penetrating

- Automation level

- Automated rotary system

- Nozzle type

- Fixed / Mobile

- Nozzle configuration

- Penetrating / Non-penetrating neck

- Machine capacity

- 2, 000 - 60, 000 bph

- Rinsing treatments

- Single / Double / Triple

- Nozzle Type

- Fixed / Mobile

- Treatment Type

- Single / Double / Triple

- Production Capacity

- 2, 000 to 60, 000 bph

- Integration with Bottling Lines

- Yes

- Sanitizing Solution Capability

- Yes

- Inert Gas Usage

- Yes

- Filtered Water Rinsing

- Yes