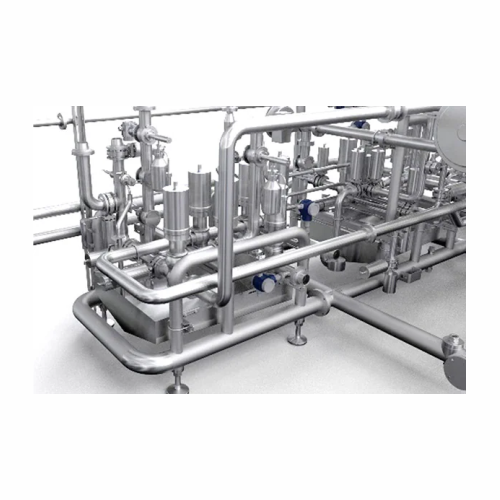

Flash pasteuriser for juices

Ensure the highest quality of juices and beverages with a versatile system that offers precise pasteurisation, carbonation, and efficient heat recovery, seamlessly integrating into your existing production line.

Processes and Pasteurises Liquids with Precision

The VarioFlash J flash pasteuriser from Krones is a versatile solution designed for the demanding needs of the food and beverage industry. It excels at ensuring microbiological safety by utilizing a hygienic plate heat exchanger system. This flash pasteuriser supports a wide range of applications, from orange juice and carbonated soft drinks to high-gravity lagers and sorghum beer, with an impressive throughput of 7,500 to 60,000 liters per hour. The integration of carbonation modules directly within the heating system is particularly notable, offering precise CO2 dosing and reducing the footprint compared to standalone solutions. Energy efficiency is enhanced thanks to a patented “Eco-hygienic Sleep Mode,” which minimizes energy and water consumption, alongside internal heat recovery of up to 95%. The design facilitates easy maintenance with features such as quick-change axial face seals and an intelligent buffer tank that balances production fluctuations. Made to integrate seamlessly into your production line, the VarioFlash J supports continuous, high-speed operations, making it ideal for juice producers and beverage manufacturers aiming for excellence in liquid product processing.

Benefits

- Enhances product quality with precise temperature control and carbonation integration.

- Minimizes operational costs through up to 95% heat recovery and efficient energy use.

- Ensures high microbiological safety with reliable pasteurization and redundant monitoring.

- Reduces downtime with quick changeovers and intelligent design for easy maintenance.

- Offers production flexibility with a scalable throughput of 7,500 to 60,000 liters per hour.

- Applications

- Juice, Sorghum beer, High-gravity brewing, Carbonated soft drinks (csd)

- End products

- Apple juice, Fermented sorghum beer, Citrus carbonated drinks, Cola beverages, Orange juice, Grape juice, Diet sodas, Strong ales, Craft barley beers, High-gravity lagers

- Steps before

- Juice extraction, Filtration, Homogenization

- Steps after

- Filling, Capping, Labeling, Packaging

- Input ingredients

- juice, carbonated soft drinks (CSD), sorghum beer, high-gravity brewing

- Output ingredients

- pasteurised juice, pasteurised CSD, pasteurised sorghum beer, pasteurised high-gravity beer

- Market info

- Krones is renowned for its expertise in manufacturing beverage and liquid food processing and packaging equipment, offering comprehensive solutions that include filling, packaging technology, and processing systems, and is reputed for innovation and quality in the industry.

- Output range

- 7, 500 to 60, 000 litres per hour

- Microbiological safety

- Line sterilisation and variable PU control

- Heat exchanger type

- Hygienic plate heat exchanger

- Heating control

- Redundant temperature control

- Buffer tank

- Integrated

- CO2 dosing accuracy

- ≦ 0.08 g/l

- Change-over time

- 30 minutes

- Energy recovery

- Internal heat recovery of up to 95 percent

- Standby mode

- "Eco-hygienic sleep mode"

- Footprint

- Considerably smaller due to integrated systems

- Product quality preservation

- High-precision PU control

- Product type compatibility

- Juice and CSD

- Output range

- 7, 500 to 60, 000 litres per hour

- Eco-hygienic sleep mode

- Stand-by operation for minimal energy and water consumption

- Line sterilisation and variable PU control

- Ensures highest microbiological safety

- Connection method

- Direct connection via swing bend panel or valve manifold

- Product buffer capability

- Integrated buffer tank

- Product heating control

- Hygienic plate heat exchanger with redundant temperature control

- Quick change-over

- Axial face seals with moveable pump slides

- Integrated carbonation

- Module directly in the heating system

- Product deaeration

- VarioSpin compact vacuum-assisted deaerator

- Abrasion resistance

- Yes

- Biological compatibility

- Food-grade materials

- Cleanability

- CIP/SIP compatible

- Corrosive resistance (e.g. acids)

- Stainless steel

- Density/particle size

- 0.5–2.5 g/cm³ / Suitable for various particle sizes

- Fields of Application

- Juice and CSD

- Machine footprint

- Considerably smaller footprint due to integrated carbonation module

- Control panel type

- Direct connection or via swing bend panel or valve manifold

- Compact footprint

- All-in-one system with no additional buffer tank needed

- Discharge method

- Direct connection via swing bend panel or valve manifold

- Design Features

- Intelligent design for easy maintenance

- Integration Possibilities

- Swing bend panel or valve manifold

- Heat Exchanger Type

- Plate heat exchanger

- Control Panel Type

- HMI with electronic data writer

- Buffer Tank Integration

- Integrated buffer tank for process decoupling

- Additional Module

- Integrated carbonation module